Description

The ABB TP858 is a high-performance industrial operator panel from ABB’s Automation Builder ecosystem,designed for seamless integration with AC 800M controllers and System 800xA process automation platforms.Featuring a bright 10.4-inch TFT color display with resistive touchscreen,it delivers intuitive HMI visualization,real-time alarm management,and secure access control for complex industrial processes in power,oil&gas,water,and manufacturing environments.

Application Scenarios

At a Scandinavian district heating plant,operators struggled with slow response times and limited diagnostics on aging monochrome panels during winter peak loads.After upgrading to the ABB TP858,they gained full-color trend graphs,one-touch valve control,and integrated alarm prioritization—reducing mean time to respond(MTTR)to pressure anomalies by 65%.The panel’s rugged design also withstood constant condensation in the boiler room without failure.This case demonstrates how the ABB TP858 transforms operator efficiency from reactive troubleshooting to proactive process oversight.

Parameter

Main Parameters Value/Description

Product Model TP858

Manufacturer ABB

Product Category Industrial Touchscreen Operator Panel(HMI)

Display Size 10.4 inches(diagonal)

Display Type TFT color LCD with resistive touchscreen

Resolution 640×480 pixels(VGA)

Backlight Life≥50,000 hours

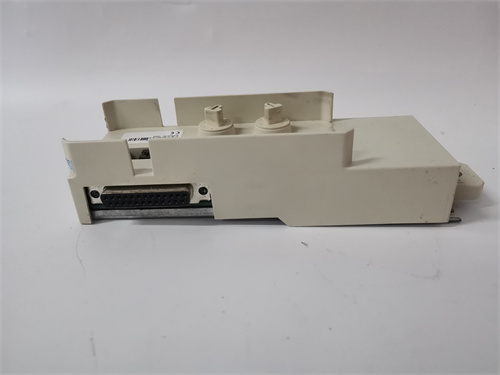

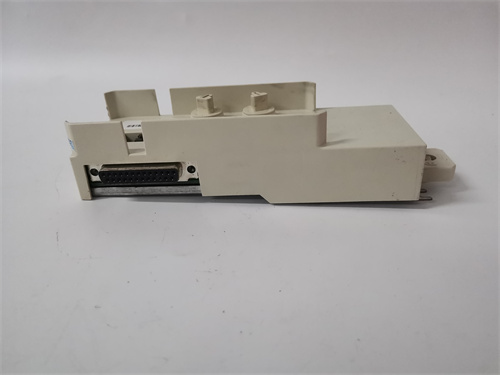

Communication Interfaces 2×Ethernet(10/100 Mbps),1×RS-485(Modbus RTU),1×USB 2.0

Supported Protocols ABB AC 800M OPC,Modbus TCP/RTU,PROFIBUS DP(via gateway)

Processor Embedded ARM-based CPU with real-time OS

Memory 128 MB flash,64 MB RAM

Environmental Rating IP65 front protection(dust/water resistant),NEMA 4X compliant

Operating Temperature 0°C to+50°C

Mounting Panel mount(flush or surface),VESA-compatible optional

Technical Principles and Innovative Values

Innovation Point 1:Native Integration with System 800xA and AC 800M–The ABB TP858 uses ABB’s proprietary communication stack to exchange data directly with AC 800M controllers without OPC middleware,ensuring sub-second update rates and synchronized alarm states across enterprise-wide 800xA systems.

Innovation Point 2:Dual-Ethernet Architecture for Segregated Traffic–One Ethernet port handles real-time control data;the other supports engineering uploads,diagnostics,or connection to plant IT networks—enhancing cybersecurity without compromising performance.

Innovation Point 3:Ruggedized Design for Harsh Environments–With IP65-rated front sealing and conformal-coated PCBs,the ABB TP858 operates reliably in high-humidity,dusty,or washdown areas where consumer-grade HMIs fail prematurely.

Innovation Point 4:Lifecycle Compatibility Across ABB Ecosystems–Projects developed in Automation Builder can be deployed unchanged across TP851(7″),TP858(10.4″),and TP861(15″)panels—accelerating design reuse and reducing training costs.

Application Cases and Industry Value

In a Middle Eastern desalination facility,the ABB TP858 replaced multiple standalone gauges and push-button stations on reverse osmosis skids.Operators now monitor permeate flow,reject pressure,and energy recovery efficiency on a single screen,with color-coded alerts for membrane fouling.Maintenance teams use the USB port to export historical logs for predictive analysis,cutting membrane replacement costs by 15%.Similarly,at a North American pulp mill,the ABB TP858 provides localized control of digester temperature and liquor circulation during network outages—thanks to its ability to cache recent setpoints and maintain basic functionality offline.

Related Product Combination Solutions

ABB AC 800M PM864A:Primary controller fully compatible with TP858 via native protocol.

ABB System 800xA:Enterprise platform where TP858 serves as a local operator node.

ABB TP851:Compact 7″version for space-constrained cabinets;shares same software base.

ABB CI854A:PROFIBUS communication module enabling TP858 integration with legacy I/O.

ABB Automation Builder:Unified engineering tool for HMI screen design,tag linking,and deployment.

ABB TB850:Mounting kit for flush installation in stainless steel panels.

ABB CP600 series:Next-generation HMI family(successor);TP858 projects can be migrated via conversion tools.

ABB DI880/DO880:Digital I/O modules often controlled via TP858 interface in local panels.

Installation,Maintenance,and Full-Cycle Support

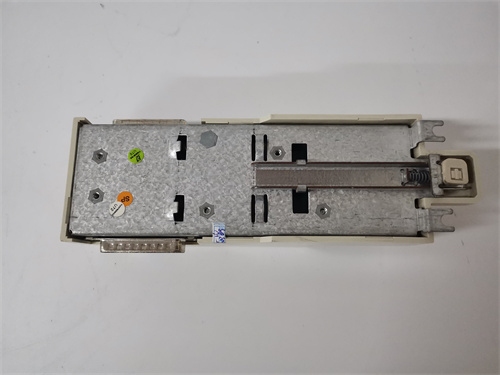

The ABB TP858 installs via standard panel cutout(288×228 mm)with included mounting brackets.Wiring uses screw terminals for power and communication,and configuration is performed through Automation Builder—allowing drag-and-drop screen creation with pre-built ABB faceplates for motors,valves,and tanks.During operation,the panel supports runtime diagnostics,including communication status,memory usage,and touchscreen calibration alerts.

We provide comprehensive support throughout the product lifecycle—from compatibility checks with your AC 800M firmware version to post-deployment screen optimization and spare unit provisioning.Every ABB TP858 we supply undergoes full functional validation:touchscreen accuracy test,Ethernet ping to simulated AC 800M,display uniformity check,and boot-up sequence verification.All units are factory-cleaned,ESD-protected,and backed by a 12-month warranty.

Contact us for a customized solution—whether you’re modernizing an existing ABB control system or deploying a new skid with local HMI needs,the ABB TP858 delivers proven reliability,seamless integration,and operator-centric design that keeps your process visible,controllable,and safe.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: