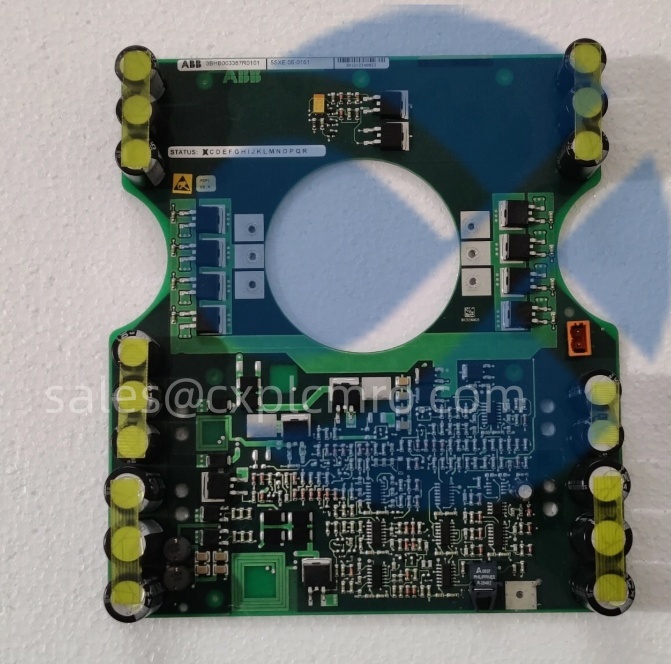

Product Description

Brand:ABB

Model:3BHB003387R0101

Series:ACS 6000 Medium Voltage Drive Components

Function:IGBT Gate Drive Unit

Core Role:Provides isolated,protected switching signals for high-power IGBTs in medium voltage variable frequency drives.

ABB 3BHB003387R0101is a high-performance,high-isolation IGBT Gate Drive Unitspecifically engineered for ABB’s ACS 6000series of medium voltage(MV)variable frequency drives.It acts as the critical interface between the drive’s low-voltage control electronics and the high-voltage,high-current IGBT(Insulated Gate Bipolar Transistor)power modules.Its function is to receive low-power control signals,amplify and isolate them,and deliver the precise voltage and current required to reliably switch the IGBTs on and off,directly impacting the quality,efficiency,and reliability of the output waveform to large motors.Genuine ABB component,essential for drive availability and performance.

Application Scenarios

In a critical induced draft(ID)fan application at a 600 MW coal-fired power plant,the fan motor is controlled by an ABB ACS 6000medium voltage drive to optimize combustion efficiency.The drive’s inverter section uses multiple high-voltage IGBTs,each requiring a perfect gate signal to switch thousands of volts and hundreds of amps.The ABB 3BHB003387R0101gate drive unit is mounted directly on each IGBT submodule.It receives a fiber-optic command from the drive’s control system and generates a robust,precisely timed+15V/-15V gate signal.More importantly,it continuously monitors the IGBT’s health in real-time.During a grid disturbance that causes a transient motor fault,the IGBT experiences a sudden current surge.The 3BHB003387R0101’s integrated Vce(sat)desaturation(DESAT)protectiondetects the abnormal voltage across the IGBT within 2-3 microsecondsand executes a controlled,soft shutdown,preventing a destructive failure that could take the fan—and potentially the entire boiler unit—offline for weeks.For the plant’s reliability engineer,the 3BHB003387R0101is not just a driver;it is the guardian of a multi-million-dollar asset.Its failure could lead to a cascade destruction of IGBTs,resulting in over$250,000 in parts and labor and catastrophic production loss.Its robust design and predictive diagnostics are paramount for maintaining base-load power generation.

Key Parameters

Parameter

Value/Description

Product Model

3BHB003387R0101

Manufacturer

ABB

Product Category

IGBT Gate Drive Unit/Interface Board

Target System

ABB ACS 6000 Series Medium Voltage Drives

Input Signal

Fiber-optic signal for control and status feedback,ensuring complete galvanic isolation.

Output Signal

Isolated gate drive voltage,typically+15V(ON)and-8V to-15V(OFF).

Isolation Voltage

Very High(typically 6-10 kV or more),suitable for medium voltage applications(2.3kV,3.3kV,4.16kV systems).

Protection Features

DESAT(Desaturation)Protectionfor short-circuit/overcurrent,Undervoltage Lockout(UVLO)for supply monitoring,Over-temperature monitoring.

Switching Speed

Optimized for the specific IGBT module,balancing switching losses and electromagnetic interference(EMI).

Power Supply

Requires isolated auxiliary DC supplies(e.g.,+24V input,internally converted to+/-gate voltages).

Feedback Signals

Provides status feedback(Ready,Fault,IGBT Temp)via the fiber-optic link to the main control board.

Status Indicators

LEDs for power status,fault indication,and communication activity.

Mounting

Directly attached to or integrated within the IGBT power submodule or press-pack package.

Primary Function

Safe switching,real-time protection,and status monitoring for a single high-power IGBT or IGBT pair.

Technical Principles and Innovative Values

The ABB 3BHB003387R0101is a pinnacle of high-power electronics design,where precision control meets rugged protection in the most electrically hostile environment inside a drive.Its innovations are focused on guaranteeing absolute reliability for the most expensive components in the system.

Innovation Point 1:Advanced,Multi-Layer Protection for Catastrophic Fault Prevention

The core intelligence of the 3BHB003387R0101lies in its multi-faceted,hardware-based protection suite.The DESAT protectionis the most critical.It monitors the collector-emitter voltage(Vce)of the IGBT during its on-state.Under a short-circuit condition,Vce rapidly increases(“desaturates”).The driver’s dedicated high-voltage diode and comparator circuit detect this within microseconds—orders of magnitude faster than software—and initiates a two-stage soft turn-off.This controlled shutdown reduces the di/dt and the resulting voltage spike(L*di/dt),minimizing stress on the IGBT and preventing failure.Combined with UVLO(which disables the driver if gate power is low,preventing linear mode operation)and over-temperature monitoring,it creates a nearly failsafe environment for the IGBT.

Innovation Point 2:High-Noise-Immunity Design and Galvanic Isolation

Operating in a cabinet with 6kV+voltage swings and high dv/dt,noise immunity is non-negotiable.The use of fiber-optic communicationfor the control signal provides perfect galvanic isolation and is completely immune to electromagnetic interference.The driver board itself employs meticulous layout with guard rings,isolated power supplies using high-frequency transformers,and shielding to prevent parasitic coupling.The negative turn-off voltage(e.g.,-15V)is crucial to counteract the”Miller effect,”where rapid voltage changes on the collector can induce enough current through the gate-collector capacitance to falsely turn the IGBT back on,potentially causing a shoot-through fault in the bridge.

Innovation Point 3:Comprehensive Diagnostics and Predictive Capabilities

This driver is an intelligent sensor,not just a switch.It continuously monitors its own health and the IGBT’s operating parameters.It reports back”Driver Ready,””IGBT Healthy,””Fault,”and often”IGBT Junction Temperature”(derived from a built-in NTC thermistor or the Vce(sat)at low current)to the main controller.This allows the drive’s diagnostic system to log trends.A gradually increasing thermal resistance or a slight change in Vce(sat)can indicate degrading solder joints or bond wires inside the IGBT module,enabling predictive maintenance.The drive can schedule a replacement during the next planned outage,avoiding a catastrophic in-service failure.

Innovation Point 4:Optimized for Serviceability and System Integration

Designed for the modular ACS 6000,the 3BHB003387R0101is part of a replaceable power submodule.This modularity is a huge maintenance advantage.Instead of troubleshooting individual components on a large PCB,technicians can replace the entire IGBT submodule(including the driver)as a unit,dramatically reducing Mean Time To Repair(MTTR).The driver is configured and tested as a matched set with its IGBT,ensuring optimal switching characteristics and reliability from the factory.

Application Cases and Industry Value

Case Study:LNG Pipeline Compressor Drive Protection

A major natural gas pipeline used an ABB ACS 6000drive to control a 15MW compressor station.The drive operated flawlessly for years until a sudden upstream pipeline pressure surge caused the compressor to approach surge conditions,creating a massive,instantaneous torque reversal and current spike on the motor.

Inside the drive,the 3BHB003387R0101gate driver on the affected IGBT leg detected the resulting DESAT condition.Within microseconds,it clamped the gate voltage and began its soft-shutdown sequence.Simultaneously,it sent a hardware fault signal back to the control system.The main drive controller received the fault,tripped the input breaker,and isolated the section.

Post-event analysis was telling:The IGBT module protected by that specific 3BHB003387R0101driver survived without damage.The diagnostic log showed a clean”DESAT Fault”on a specific phase,timestamped to the microsecond.In contrast,a similar event on a competitor’s drive at another station,lacking such fast protection,had resulted in the explosion of multiple IGBT modules,causing a 6-week outage for rebuild.

The value delivered was monumental:1.Asset Protection:The driver’s ultra-fast protection saved an IGBT submodule worth over$40,000.2.Minimized Downtime:Because the fault was contained,technicians replaced the single driver/IGBT submodule(a spare part held on-site)during a planned 8-hour maintenance window two days later.The alternative could have been a multi-week,unplanned outage.3.Precose Fault Analysis:The precise diagnostic data allowed engineers to understand the root cause(pipeline surge)and implement control system changes to prevent recurrence.The pipeline operator stated,”The intelligence and speed of the ABB gate driver turned a potential disaster into a manageable maintenance event.It proved its worth a hundred times over.”

Related Product Combination Solutions

The 3BHB003387R0101is an integral part of a high-power drive’s power stack.Key related components include:

ABB IGBT Power Submodule/Press-Pack:The high-voltage,high-current IGBT that the 3BHB003387R0101directly drives and protects.They are a matched pair.

ABB ACS 6000 Main Control Unit(e.g.,NAMC-11):The central controller that generates the original PWM signals sent via the fiber-optic network to the gate drivers.

ABB Fiber-Optic Interface Board:Distributes the light signals from the controller to the individual gate driver units in the inverter tiers.

ABB Gate Power Supply Unit:Provides the isolated low-voltage power(e.g.,+24V)to each gate driver board within the power stack.

ABB Current Sensor Module:Measures the output phase current.The DESAT protection in the driver is a local,hardware backup to the current-based protection in the main controller.

ABB Clamping/Snubber Circuitry:Works in conjunction with the driver’s soft-shutdown to limit overvoltage spikes during switching or faults.

ABB Cooling System(Water/Air):Critical for maintaining the driver and IGBT within their thermal operating limits.The driver’s temperature feedback is a key input for cooling control.

ACS 6000 Diagnostic and Service Tool:Software used to monitor the status and fault history of all 3BHB003387R0101drivers in the system.

Installation,Maintenance,and Full-Cycle Support

Installation&Handling(CRITICAL):This is a static-sensitive and voltage-critical component.Always use an ESD wrist strap and handle the board by its edges.Installation is typically part of replacing an entire IGBT submodule.Ensure all power is disconnected,DC links are discharged,and safety locks are applied.The driver is often connected via a multi-pin connector to the IGBT.Alignment is crucial;bent pins can cause catastrophic failure.Reconnect fiber-optic cables carefully,ensuring they are clean and fully seated.Never power a drive after IGBT/driver replacement without first performing a thorough static functional testof the driver using a specialized tester to verify proper output voltages and protection logic.

Testing&Commissioning:After hardware installation,the drive system performs automated startup tests.These include checking the insulation resistance of the DC bus and IGBTs,and verifying communication with all gate drivers.Use the drive’s service software to monitor the status of each 3BHB003387R0101;they should all report”Ready.”A low-power voltage test(applying a reduced DC bus voltage)is often performed to validate switching in all inverter legs before full power is applied.

Routine Maintenance&Predictive Diagnostics:There is no scheduled maintenance for the driver itself.The focus is on its operating environment.Monitor cooling system performancereligiously;over-temperature is a primary stressor.Use the drive’s built-in diagnostic functions to periodically log and trend the IGBT junction temperatureand DESAT event countersfor each driver.A gradual rise in operating temperature for a specific IGBT/driver pair can indicate a failing thermal interface.Keep the drive cabinet clean and ensure air filters are changed regularly.

Troubleshooting:A faulty driver will typically cause a hardware fault(e.g.,”SHORT CIRCUIT,””DRIVER FAULT”)on a specific inverter cell.The drive diagnostics will pinpoint the cell and leg.Do not attempt to repair the driver board.The standard procedure is to replace the entire IGBT submodule(including the driver).Before replacement,use a multimeter to check for obvious shorts across the IGBT terminals.Our technical support can guide you through the diagnostic logs to confirm the driver is the root cause before committing to a costly submodule replacement.

Our Commitment:We supply 100%genuine,factory-tested ABB 3BHB003387R0101IGBT Gate Drive Units.Given its critical role,each unit we source is verified for authenticity and comes from certified supply channels.We recommend pairing it with a genuine ABB IGBT submodule for guaranteed performance and safety.We provide a 12-month warrantyand can offer expert guidance on drive system diagnostics and safe handling procedures for these sensitive components.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: