Description

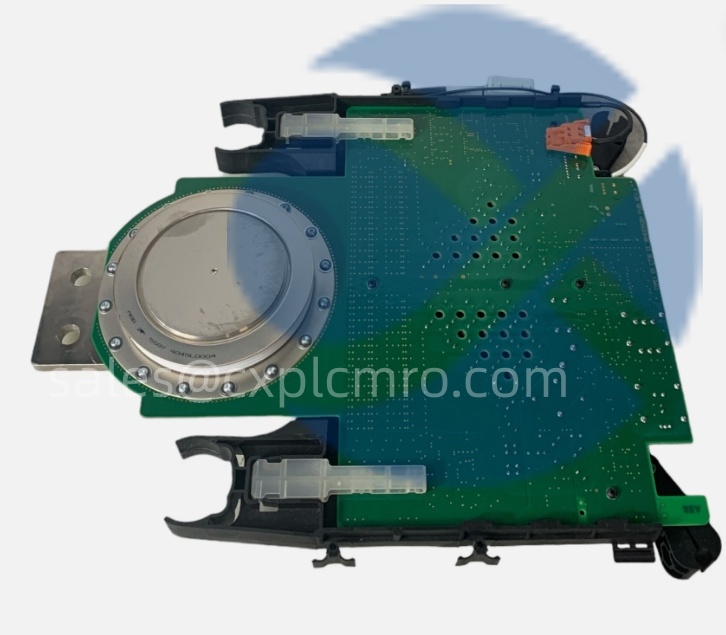

The ABB 3BHB021400R0002 is the model number for the PM866AK01,a high-end programmable automation controller(PAC)in ABB’s AC 800M family,featuring enhanced processing power,large memory,and native support for redundancy and industrial communication protocols.Paired with the ABB 3BHE039203R0101,which corresponds to the TB850A,a 16-slot S800 I/O baseplate with integrated power management and hot-swap capability,this combination forms a robust,scalable control backbone for complex industrial systems.

Together,they enable seamless integration of analog,digital,and specialty I/O modules—delivering deterministic performance,cybersecurity readiness,and decades-long lifecycle support.

Application Scenarios

At a greenfield LNG liquefaction facility in Qatar,engineers needed a control system capable of managing over 12,000 I/O points across cryogenic compressors,flare systems,and safety shutdown logic—all while meeting SIL 3 requirements.They selected redundant ABB 3BHB021400R0002 PM866AK01 controllers mounted on 3BHE039203R0101 TB850A baseplates distributed across 28 I/O cabinets.The TB850A’s hot-swap functionality allowed technicians to replace failed DI/DO modules during live operation,while the PM866AK01’s dual-core processor executed safety and basic process control in parallel without jitter.During commissioning,the system achieved<5 ms scan time for critical loops and zero unplanned outages in its first year—proving that scalability and reliability can coexist.

Parameter

Main Parameters Value/Description

Product Model(Controller)3BHB021400R0002(PM866AK01)

Product Model(Baseplate)3BHE039203R0101(TB850A)

Manufacturer ABB(Hitachi Energy)

Product Category AC 800M Programmable Controller+S800 I/O Baseplate

CPU Architecture Dual-core 1 GHz ARM Cortex-A9,1 GB DDR3 RAM,4 GB flash

Redundancy Support Yes—full hot-standby with<10 ms switchover(requires RLM01)

Communication Interfaces 2×10/100/1000 Mbps Ethernet(PROFINET,Modbus TCP,Ethernet/IP),serial port

I/O Baseplate Slots 16 slots—supports all S800 I/O modules(AI,AO,DI,DO,specialty)

Hot-Swap Capability Yes—field modules can be replaced without powering down the baseplate

Power Input 24 V DC(redundant power inputs supported via dual PSU connection)

Diagnostic Features Per-slot LED status,module presence detection,thermal&overcurrent monitoring

Operating Temperature 0°C to+60°C(conformal-coated PCB;extended temp options available)

Mounting Standard 35 mm DIN rail;compatible with ABB cabinet systems

Certifications IEC 61508(SIL 3 ready),CE,UL,ATEX(when installed in certified enclosures)

Technical Principles and Innovative Values

Innovation Point 1:Unified Hardware Platform for Basic&Safety Control

The PM866AK01(3BHB021400R0002)runs both standard PLC logic and certified safety applications(via AC 800M Safety Option)on the same hardware—eliminating separate safety controllers and reducing engineering complexity.

Innovation Point 2:Intelligent Power Management on TB850A

The 3BHE039203R0101 TB850A features independent power domains per slot group,current limiting,and automatic fault isolation.If a short occurs in one module,adjacent channels remain powered—maximizing availability.

Innovation Point 3:Deterministic Multi-Protocol Communication

Unlike generic industrial PCs,the PM866AK01 uses hardware-accelerated protocol stacks,ensuring PROFINET IRT and Modbus TCP coexist without timing interference—critical for motion and process synchronization.

Innovation Point 4:Lifecycle Security&Firmware Integrity

Both units support secure boot,encrypted firmware updates,and role-based access—ensuring compliance with IEC 62443 cybersecurity standards throughout their 15+year operational life.

Application Cases and Industry Value

In a European steel mill modernizing its continuous caster,the legacy DCS was replaced by an AC 800M system built around PM866AK01 controllers and TB850A baseplates.The caster requires microsecond-level coordination between mold oscillation,spray cooling,and strand pulling.The 3BHB021400R0002 delivered consistent 2 ms scan cycles across 3,200 I/O points,while the 3BHE039203R0101’s hot-swap feature reduced maintenance downtime by 75%.Annual production increased by 120,000 tons due to fewer breaks and higher casting speeds.

In another case,a U.S.biopharma plant deployed this duo for aseptic filling lines requiring FDA 21 CFR Part 11 compliance.The audit trail,electronic signatures,and secure data logging—enabled by the PM866AK01’s embedded historian and the TB850A’s reliable I/O capture—passed FDA inspection on the first attempt.

Related Product Combination Solutions

ABB RLM01(3BDZ000398R1)–Redundancy link module for pairing two 3BHB021400R0002 controllers

ABB DI820(3BSE022170R1)–16-channel digital input module fully compatible with 3BHE039203R0101

ABB AI810(3BSE008515R1)–High-accuracy analog input card for temperature/pressure signals

ABB CI874(3BSE043844R1)–PROFINET IO Controller module for connecting remote I/O

ABB PSU851(3BSE013207R1)–Redundant 24 V DC power supply for TB850A baseplate

ABB Control Builder M–Engineering suite for programming,diagnostics,and HMI integration

ABB DATX110/DATX120(3ASC25H209/3ASC25H210)–Terminal bases for simplified field wiring to I/O modules on TB850A

ABB Panel PC or Compact HMI–Operator interface tightly integrated with PM866AK01 via OPC UA

Installation,Maintenance,and Full-Cycle Support

Installing the 3BHB021400R0002 and 3BHE039203R0101 begins with DIN-rail mounting in a ventilated,EMI-shielded enclosure.The TB850A connects to redundant 24 V DC supplies via spring-clamp terminals,while the PM866AK01 links to the baseplate via a high-density backplane connector.Fiber or copper Ethernet cables connect to enterprise and field networks using shielded RJ45 or SC connectors.

Maintenance is streamlined by comprehensive diagnostics:the TB850A indicates module presence,power faults,and communication errors via LEDs,while the PM866AK01 logs events in non-volatile memory.Hot-swap allows I/O replacement during operation,and firmware updates can be performed remotely with rollback capability.

Every 3BHB021400R0002 and 3BHE039203R0101 unit we supply undergoes functional burn-in testing,including redundancy failover,I/O stress,and thermal cycling.All are genuine ABB products with full traceability,backed by a 12-month warranty and direct access to ABB-certified automation specialists for lifecycle support—from design to decommissioning.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: