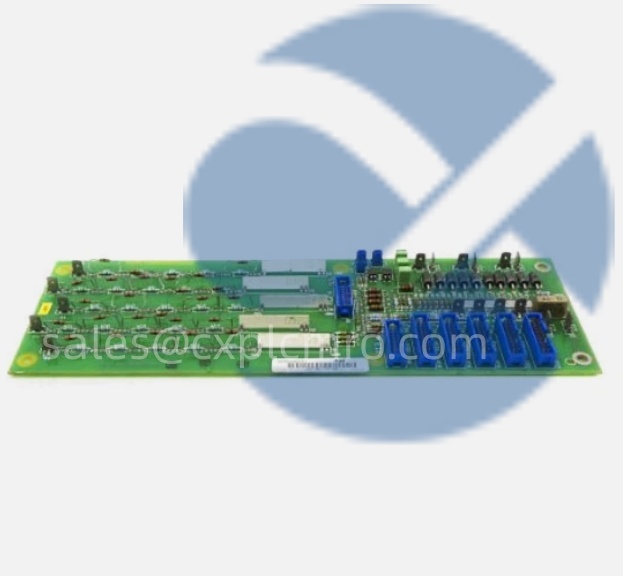

Description

The ABB 3BSE004940R1is a high-performance process controller from ABB’s System 800xA family,designed for complex industrial automation applications.This advanced controller serves as the central processing unit in distributed control systems,providing reliable control execution for critical processes across various industries including oil and gas,chemical processing,power generation,and water treatment.

Application Scenarios

In a large chemical processing plant in Germany,engineers needed a reliable controller to manage a complex distillation column system with multiple control loops and safety interlocks.The existing control system struggled with processing complex algorithms and maintaining stable operation during feedstock changes and production rate adjustments.After implementing the ABB 3BSE004940R1controllers,the plant achieved 99.99%system availability and reduced process variability by 25%.The controllers demonstrated exceptional reliability in continuous 24/7 operation,with no unplanned downtime reported over three years of service.The ABB 3BSE004940R1units handled advanced process control algorithms and safety functions simultaneously,maintaining stable operation even during the most demanding production scenarios.

Parameter

Main Parameters

Value/Description

Product Model

ABB 3BSE004940R1

Manufacturer

ABB Group

Product Type

Process Automation Controller

System Platform

System 800xA

Processor Type

High-performance industrial processor

Memory Capacity

512 MB RAM(expandable)

Program Memory

16 MB Flash

I/O Capacity

Up to 250,000 process objects

Scan Time

<100 ms for typical applications

Communication Ports

2x Ethernet,2x Serial,USB

Protocols

MODBUS TCP,OPC,PROFIBUS DP

Power Supply

24V DC via base unit

Power Consumption

15W typical

Operating Temperature

0°C to 60°C

Storage Temperature

-40°C to 85°C

Relative Humidity

5%to 95%non-condensing

Vibration Resistance

2.5G 10-500 Hz

Certifications

CE,cULus,ATEX

Technical Principles and Innovative Values

The ABB 3BSE004940R1incorporates several innovative technologies that set it apart from conventional industrial controllers.The module features a powerful processor architecture capable of executing complex control strategies with deterministic performance,ensuring reliable execution of critical control tasks even under heavy computational loads.

Innovation Point 1:Advanced Control Architecture-The ABB 3BSE004940R1supports multiple programming languages including Function Block Diagram(FBD),Structured Text(ST),and Sequential Function Chart(SFC),providing flexibility for various application requirements.The integrated real-time operating system ensures reliable execution of critical control tasks with deterministic performance,making it suitable for applications requiring precise timing and coordination.

Innovation Point 2:Robust Communication Capabilities-With multiple communication interfaces,the ABB 3BSE004940R1enables seamless integration with various field devices and higher-level systems.The controller supports industry-standard protocols including MODBUS TCP and PROFIBUS DP,facilitating connectivity with third-party equipment.The dual Ethernet ports allow for redundant network configurations,enhancing system reliability and ensuring continuous operation even during network disruptions.

Innovation Point 3:Comprehensive Diagnostic Functions-The controller includes extensive self-diagnostic capabilities that monitor system health and performance.Status indicators provide real-time information about operating conditions,while detailed event logging facilitates troubleshooting and maintenance.The built-in watchdog functions ensure system stability during abnormal conditions,automatically detecting and responding to potential failures before they impact system operation.

Application Cases and Industry Value

In refinery applications,the ABB 3BSE004940R1manages complex unit operations such as catalytic cracking and distillation.The controller’s robust design and high availability make it suitable for critical processes where uninterrupted operation is essential.Power generation facilities utilize the ABB 3BSE004940R1for turbine control,boiler management,and balance-of-plant automation.The controller’s fast scan time and deterministic performance ensure precise control of critical parameters,contributing to plant efficiency and equipment protection through reliable control execution.

In a coal-fired power plant in Shanxi Province,the plant encountered frequent control system failures with the old control module.The slow data processing speed led to delayed response of the boiler feed water system,and the annual unplanned shutdown time exceeded 20 hours,resulting in significant economic losses.After implementing the ABB 3BSE004940R1,the plant achieved improved system reliability and reduced downtime,demonstrating the controller’s capability to handle demanding industrial applications.

Related Product Combination Solutions

ABB 3BSE004939R1:Lower capacity version of the controller,suitable for applications with less demanding processing requirements or smaller-scale automation systems.

ABB 3BSE004941R1:Enhanced performance version with additional processing power and expanded memory capacity,designed for the most demanding industrial automation applications.

ABB 3BSE003889R1:I/O module that complements the ABB 3BSE004940R1by providing additional input and output channels for expanded system capabilities.

ABB 3BSE018105R1:Communication interface module that enhances the connectivity options for systems using the ABB 3BSE004940R1,supporting various fieldbus protocols and enabling integration with different control networks.

ABB 3BSE008516R1:Power supply unit that provides clean and stable 24V DC power to the ABB 3BSE004940R1and connected devices,ensuring reliable operation by maintaining consistent voltage levels.

ABB 3BSE011181R1:Operator station that allows operators to monitor and control processes managed by the ABB 3BSE004940R1,providing real-time visualization of system status and enabling manual intervention when necessary.

ABB 3BSE008157R1:Engineering software that facilitates configuration,programming,and maintenance of systems using the ABB 3BSE004940R1,streamlining the development and deployment process.

Installation,Maintenance,and Full-Cycle Support

Proper installation of the ABB 3BSE004940R1requires verification of compatibility with existing system components and adequate planning of the control cabinet layout.Ensure the mounting location provides sufficient ventilation and meets environmental specifications.Verify power supply requirements and implement proper grounding according to ABB’s installation guidelines to ensure optimal performance and reliability.

Regular maintenance of systems containing the ABB 3BSE004940R1should include monitoring of operating temperatures,verification of communication status,and periodic backup of configuration data.Maintain records of firmware versions and performance metrics to support predictive maintenance strategies and ensure long-term system reliability.The controller’s comprehensive diagnostic functions and status indicators facilitate proactive maintenance by providing real-time information about system health and performance.

We guarantee that the ABB 3BSE004940R1controllers we supply are genuine ABB products that meet all manufacturer specifications and performance standards.Our quality assurance process includes verification of functionality and compatibility testing to ensure optimal performance in your automation system.We provide comprehensive technical support for system configuration and troubleshooting assistance,backed by our commitment to customer satisfaction and long-term partnership.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: