Product Description

Description:

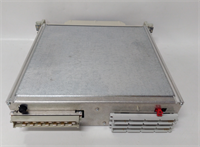

This comprehensive bundle comprises three critical components from ABB’s Advant OCS(Open Control System)platform:the 216NG63Acontroller,the HESG441635R1power supply module,and the HESG216879/Kbase unit.Together,they form a complete control engine for mid-range automation applications,delivering reliable process control and data handling capabilities.This integrated solution ensures seamless operation in demanding industrial environments.

Application Scenarios:

In a pharmaceutical manufacturing facility requiring precise batch process control,maintaining recipe integrity and compliance with FDA 21 CFR Part 11 regulations is paramount.The ABB Advant OCS platform,built around the 216NG63Acontroller,manages complex sequencing,temperature control,and material tracking.The HESG441635R1power supply ensures clean,stable power to the processor even during minor voltage fluctuations,preventing uncontrolled shutdowns that could ruin a batch worth thousands of dollars.The HESG216879/Kbase unit provides the robust physical and electrical backbone,allowing for the integration of additional I/O modules like analog and digital cards.A real-world case involved a biotech company that upgraded its fermentation control system using this bundle,resulting in a 15%reduction in batch cycle time and eliminating data integrity alarms caused by their previous unstable control hardware.

Parameter:

Main Parameters

Value/Description

Primary Model

216NG63A(Controller Module)

Power Supply Model

HESG441635R1

Base Unit Model

HESG216879/K

Manufacturer

ABB

System Platform

Advant OCS/MOD 300

Controller Type

AC 410 Series Process Controller

Memory Capacity

Sufficient for complex logic and data logging

Power Input

115/230V AC(for HESG441635R1)

Communication

MasterBus/Plant Network Connectivity

I/O Compatibility

Wide range of S800 I/O modules

Operating Temperature

0°C to 60°C

Certifications

cULus,CE,ATEX options

Technical Principles and Innovative Values:

This component set represents a modular,distributed control philosophy that was advanced for its time and remains robust today.

Innovation Point 1:Decoupled Redundancy Architecture.A key strength of this platform is its flexible redundancy.The 216NG63Acontroller can be configured in a 1:1 hot-standby pair.In this setup,if the primary controller fails,the secondary 216NG63Atakes over control seamlessly without process disruption.The HESG441635R1power supply can also be paired redundantly,and the entire assembly slides into the HESG216879/Kbase unit,which facilitates the inter-module communications for this switchover.This provides fault tolerance at both the processing and power levels,a critical feature for continuous processes.

Innovation Point 2:Integrated System Diagnostics.The 216NG63Acontroller,in conjunction with the base unit,provides extensive diagnostic capabilities that are accessible from the operator station.It can monitor its own health,the status of the HESG441635R1power supply,and the communication links to I/O modules.This proactive monitoring allows maintenance teams to identify and replace a failing power supply or controller during a planned outage,thereby avoiding unplanned downtime.This predictive maintenance capability is a significant operational advantage.

Innovation Point 3:Scalable I/O Structure.The HESG216879/Kbase unit is not just a passive carrier;it is an intelligent part of the system that manages the data exchange between the 216NG63Aprocessor and the various I/O modules(e.g.,analog input,digital output cards)that plug into it.This creates a scalable local cluster where I/O processing is distributed,reducing the load on the main controller and improving overall system speed and determinism.

Application Cases and Industry Value:

Case 1:Power Plant Water Treatment System Modernization.A coal-fired power plant needed to upgrade the control system for its chemical feed and water purification system without a complete rip-and-replace of existing field wiring.The team used the ABB 216NG63Acontroller bundle as a direct replacement for an older,obsolete controller.The HESG216879/Kbase unit accepted the existing I/O cards,minimizing retrofit time and cost.The new system,powered by the reliable HESG441635R1,provided more precise control of chemical dosing,reducing chemical consumption by 7%and improving effluent quality to meet new environmental standards.

Case 2:Offshore Platform Compressor Control.On an offshore gas platform,space and reliability are at a premium.The platform’s export gas compressor anti-surge and sequencing control was managed by a system centered on the 216NG63A.The robustness of the HESG441635R1power supply in dealing with variable generator power and the high availability of the controller platform were critical.The system’s reliability prevented compressor surges that could lead to trip events and production shutdowns,each costing hundreds of thousands of dollars per day in lost production.

Related Product Combination Solutions:

To build a fully functional control station,this core bundle integrates with:

SD 822/SD 823Analog I/O Modules:For connecting 4-20 mA process signals(inputs)and outputting control signals to valve positioners.

SD 831Digital Input Module:For reading contact closures from switches and relays.

SD 832Digital Output Module:For commanding solenoid valves,motor starters,and alarms.

HESG216877/KExpansion Base Unit:To increase the I/O capacity of the 216NG63Acontroller.

HESG447000Communication Module(e.g.,for Profibus DP):To network the Advant station with third-party devices like variable frequency drives.

216VC62Aor 216UA61Communication Interface:For connecting to the higher-level Advant Station operat or interface.

Installation,Maintenance,and Full-Cycle Support:

Installing this controller bundle requires careful planning.First,the HESG216879/Kbase unit is securely mounted on the DIN rail in the control cabinet.The HESG441635R1power supply is then inserted into its designated slot and wired to the AC mains via an appropriately rated circuit breaker.Finally,the 216NG63Acontroller module is carefully aligned and pressed into the base unit until the locking lever engages.Configuration is performed using ABB’s control builder software,where the controller type and I/O configuration are defined.

Routine maintenance primarily involves monitoring the system’s diagnostic pages for any early warnings from the 216NG63Aor the HESG441635R1power supply.For critical applications,keeping a pre-configured spare 216NG63Acontroller on site allows for rapid replacement in the event of a failure,minimizing downtime.We provide all components in this bundle as original ABB equipment.Each unit undergoes testing to verify functionality prior to shipment.We offer a 12-month warranty and technical support to assist with compatibility verification and integration guidance for your specific Advant OCS application.

Contact us for a complete solution to maintain or upgrade your critical process control system with genuine,tested ABB components.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: