Description

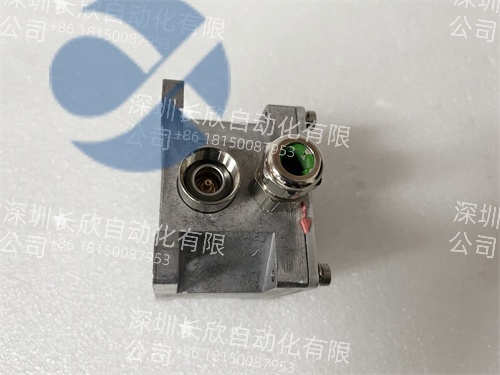

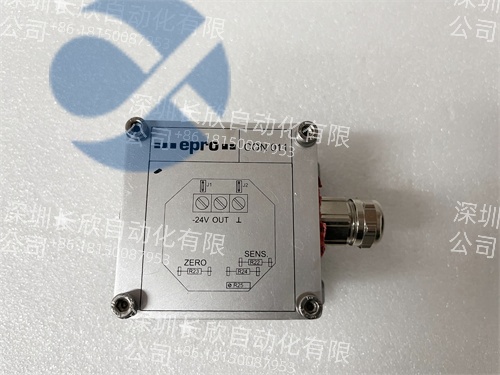

The EPRO CON021is a specialized converter module manufactured by epro GmbH(now part of Baker Hughes Bently Nevada),designed for the PR 6423 series of eddy current proximity probe systems.This industrial-grade module serves as the critical signal conditioning interface,converting raw sensor signals from proximity probes into precise,standardized measurements of shaft vibration and position for machinery protection and condition monitoring.

Application Scenarios

In a critical natural gas compressor station,the high-speed rotor’s radial vibration must be constantly monitored.A sudden increase in vibration amplitude could indicate developing imbalance,misalignment,or bearing wear.If undetected,this can escalate into a catastrophic failure,causing weeks of downtime,costly repairs,and significant revenue loss.The EPRO CON021is deployed as the essential translator in this protective system.It takes the high-frequency,low-voltage signal from the non-contact eddy current probes mounted near the compressor shaft and converts it into two key,industry-standard outputs:a DC voltage proportional to the average gap(position)and an AC voltage proportional to the dynamic vibration(peak-to-peak displacement).This reliable,conditioned signal feeds directly into a monitoring system like the MMS 6000,enabling both real-time protection trips and trend analysis for predictive maintenance,safeguarding millions of dollars in capital equipment.

Parameter

Main Parameters

Value/Description

Product Model

EPRO CON021

Manufacturer

epro GmbH(Baker Hughes Bently Nevada)

Product Category

Proximity Probe Converter/Signal Conditioner

Compatible System

PR 6423…Series Proximity Probes&MMS 6000/MMS 3000 Monitoring Systems

Function

Converts raw eddy current probe signal to Gap DC(-2 to-18V)and Vibration AC(0 to-20V pk-pk)outputs.

Input

Raw signal from PR 6423 series proximity probe(connected via coaxial cable).

Gap DC Output

-2 V to-18 V DC,linearly proportional to the average distance between the probe tip and the shaft(typically 0.5 to 2.0 mm).

Vibration AC Output

0 to-20 V peak-to-peak AC,proportional to the dynamic vibration displacement of the shaft.

Frequency Response

Typically 0 to 10,000 Hz.Captures both slow-roll and high-frequency vibration components.

Linearity

High linearity across its specified measuring range.Ensures accurate representation of shaft motion.

Power Supply

Requires±15 V DC or+24 V DC supply(depending on version).Standard industrial control voltages.

Mounting

Designed for DIN rail mounting or panel mounting.Facilitates easy installation in control cabinets.

Connections

Screw terminal blocks for power,input,and outputs.Provides secure and reliable connections.

Technical Principles and Innovative Values

Innovation Point 1:Dedicated Signal Demodulation for Dual-Parameter Extraction.The core innovation of the EPRO CON021lies in its precise analog signal processing.An eddy current probe’s output is a radio frequency(RF)signal whose amplitude is modulated by the distance to the conductive target(the shaft).The module expertly demodulates this signal.It separates the slowly varying average distance(the DC component,representing the static gap or position)from the rapidly varying component caused by shaft vibration(the AC component).Providing these two distinct,conditioned outputs from a single sensor is highly efficient,reducing wiring and sensor count while delivering comprehensive data for both protection(vibration)and alignment/clearance monitoring(gap).

Innovation Point 2:Robust Industrial Design for Critical Environments.This converter is built to perform reliably in electrically noisy industrial settings near high-power machinery.Its circuitry is designed with filtering and shielding to reject electromagnetic interference(EMI)that could corrupt the sensitive probe signal.The use of robust terminal blocks and a sturdy housing ensures long-term connection integrity despite vibration transmitted through the cabinet.This focus on inherent reliability makes it a trusted component in safety-critical machinery protection systems,where a false signal or failure could have severe consequences.

Innovation Point 3:Seamless Integration into Standardized Monitoring Architectures.The EPRO CON021is not a standalone device;it is a key building block within epro’s and compatible third-party monitoring ecosystems.Its standardized output voltages(-2 to-18V DC for gap,0 to-20V AC for vibration)are designed to be directly compatible with the input cards of monitoring systems like the epro MMS 6000,MMS 3000,or other PLC/DCS analog input modules.This plug-and-play compatibility simplifies system engineering,reduces integration time,and ensures that the high-fidelity data from the probe is accurately delivered to the system responsible for making protection decisions.

Application Cases and Industry Value

Case Study:Hydroelectric Turbine-Generator Protection.A large hydroelectric plant was experiencing intermittent alarms on one of its main turbine-generator units.The alarms suggested high vibration,but were sporadic and difficult to diagnose.The signals from the existing EPRO CON021converters feeding the vibration monitors were analyzed in detail.By examining both the AC vibration output and the DC gap voltage,engineers noticed a correlation:the vibration spikes occurred simultaneously with subtle,rapid shifts in the DC gap reading.This pattern pointed not to a mechanical fault,but to an electrical issue—likely small discharges(arcing)in the generator affecting the eddy current probe’s field.This precise diagnosis,enabled by the converter’s clear separation of dynamic and static signals,prevented an unnecessary and costly mechanical inspection.Instead,the generator’s electrical system was serviced during a planned outage,resolving the root cause and securing the unit’s reliable operation.This demonstrates the module’s value in enabling accurate diagnostics,preventing misguided maintenance,and protecting revenue.

Related Product Combination Solutions

A complete machinery monitoring point centered on the EPRO CON021typically involves these components:

EPRO PR 6423…:The specific eddy current proximity probe(e.g.,PR 6423/000-030)that provides the raw signal.

EPRO PR 9268/…:A related seismic velocity sensor,often used alongside proximity probes for casing vibration.

EPRO MMS 6310:A monitoring module in the MMS 6000 system that accepts the conditioned signals from the CON021for evaluation and alarm generation.

EPRO MMS 6851:A power supply module for the MMS 6000 rack that provides power to the monitoring modules and,indirectly,to field devices.

EPRO MMS 6110:A Keyphasor®module,essential for providing a once-per-revolution pulse to enable phase measurement for vibration analysis.

EPRO MMS 3210 TSI System:A complete Turbine Supervisory Instrumentation rack that would house multiple CON021converters and monitoring modules.

Coaxial Cable&Connectors:Specialized low-loss cable(e.g,PR 6423 cable)to connect the probe to the converter without signal degradation.

Installation,Maintenance,and Full-Cycle Support

Installation and Commissioning:Proper installation begins with correct probe mounting and gap setting on the machinery,which is critical for generating a valid signal.The EPRO CON021is then mounted on a DIN rail inside a protected cabinet.Wiring must follow strict guidelines:using the specified coaxial cable for the probe input,ensuring proper shield grounding at the converter(usually one end only),and separating signal lines from power cables.Commissioning involves powering the module and verifying its outputs.With the shaft stationary,the DC gap voltage should correspond to the mechanical gap.A simple”tap test”on the probe or machinery can verify the AC vibration output is responsive.These outputs are then connected to and scaled correctly within the monitoring system.

Maintenance and Lifecycle Support:The module is designed for continuous operation with minimal maintenance.Routine checks involve verifying power supply voltages and inspecting terminal connections for tightness.Calibration is typically performed as a system check,verifying the entire loop from probe to monitoring system using a calibration oscillator that simulates the probe signal.We provide comprehensive support for the EPRO CON021and its associated systems.This includes supplying genuine epro/Baker Hughes components,offering technical guidance on system design and troubleshooting,and assisting with signal interpretation and integration challenges.Understanding that this module is part of your plant’s protective”immune system,”we ensure the solutions we provide are reliable and technically sound.Contact us for application support,system audits,and a reliable supply of critical spares to maintain your machinery protection integrity.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: