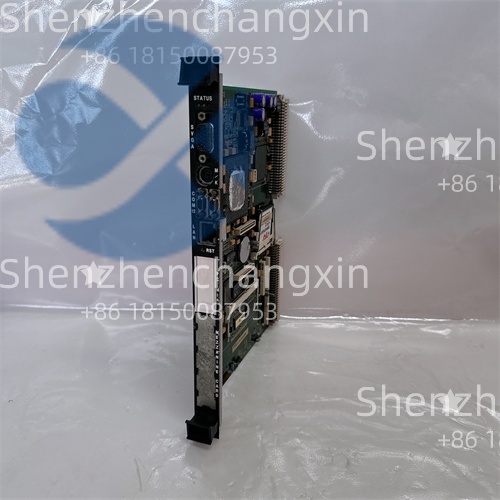

Description

The GE IS215ACLEH1Ais a critical control module within GE’s Mark VIe Speedtronic turbine control system,functioning as an analog control loop interface and I/O pack controller.This sophisticated hardware component serves as the essential bridge between the turbine’s central processing units and the myriad of analog field devices—such as temperature sensors,pressure transmitters,and position feedback units—that monitor and govern the turbine’s operation.

Application Scenarios

Within the tightly controlled environment of a combined-cycle power plant’s gas turbine enclosure,thousands of analog signals must be sampled,conditioned,and acted upon with split-second precision.Consider the critical task of controlling exhaust gas temperature,which directly impacts efficiency,emissions,and component life.The IS215ACLEH1Amodule is responsible for interfacing with the arrays of thermocouples lining the turbine’s exhaust duct.It performs high-speed,high-resolution analog-to-digital conversion,applies necessary linearization and cold-junction compensation for the thermocouples,and places the validated temperature data onto the control network.For the control engineer,the integrity of this module means that the complex algorithms regulating fuel flow and inlet guide vane position receive flawless data,enabling the turbine to operate at its thermodynamic optimum while staying within safe boundaries.A failure here could lead to inefficient combustion,excessive emissions,or a protective trip—pain points directly mitigated by the module’s robust design and diagnostic capabilities.

Parameter

Main Parameters

Value/Description

Product Model

IS215ACLEH1A

Manufacturer

GE Power(General Electric)

Product Category

Analog Control Loop/I/O Pack Module

System Compatibility

Mark VIe Speedtronic Turbine Control System

Primary Function

Analog Input Signal Conditioning&Processing Interfaces with analog field devices like thermocouples,RTDs,and 4-20mA transmitters.

Signal Types Supported

Thermocouples(Types J,K,T,E,etc.),RTDs,0-10V,4-20mA

Channel Count

Typically 16 or 32 channels per module(high-density)Maximizes I/O point density within the control rack.

Resolution

16-bit Analog-to-Digital Converter(ADC)Provides high measurement precision for sensitive control loops.

Sample Rate

Configurable,suitable for process control speeds

Built-in Diagnostics

Open wire detection,out-of-range checking,module health monitoring

Communication Interface

VME or PCI-based backplane to controller network

Operating Temperature

0°C to+60°C(Commercial Grade)/-40°C to+70°C(Extended Grade)

Power Requirement

+5 VDC and+/-12 VDC or+24 VDC via backplane

Certifications

Designed to meet UL,CE,and other regional standards for industrial control equipment.

Technical Principles and Innovative Values

Innovation Point 1:Intelligent Signal Conditioning with Auto-Identification.The IS215ACLEH1Agoes beyond simple analog conversion.It incorporates intelligent per-channel configuration where the type of sensor(e.g.,Type K thermocouple vs.4-20mA)can be defined in software.For thermocouples,it automatically applies the correct polynomial linearization and cold-junction compensation based on an onboard temperature sensor,delivering highly accurate engineering-unit readings directly to the control application without additional processing overhead in the main CPU.

Innovation Point 2:High-Density Design with Channel-to-Channel Isolation.Achieving a high channel count in a single slot is an economic and spatial necessity in modern turbine control.The IS215ACLEH1Aaccomplishes this using advanced multiplexing and sampling techniques.Critically,it maintains sufficient channel-to-channel isolation—either through optical or transformer isolation—to prevent ground loops and noise from one noisy sensor(like a spark plug ionization signal)from corrupting measurements on adjacent sensitive channels(like exhaust thermocouples).

Innovation Point 3:Predictive Diagnostic Front-End.Reliability in a turbine control system is paramount.This module embeds diagnostic routines that run concurrently with normal operation.It can detect a failing sensor(like a drifting RTD)by analyzing signal noise and stability,and it definitively identifies hard failures like open thermocouple wires or shorted transmitters.By flagging these issues early,it transitions from a mere data acquisition device to a predictive maintenance tool,allowing repairs to be planned during scheduled outages rather than reacting to a control failure.

Application Cases and Industry Value

Case Study:Enhancing Flexibility and Reliability in a Peaking Plant.A power utility operating aeroderivative gas turbines for grid frequency regulation needed to improve start-up reliability and operational flexibility.Their existing control system’s analog input modules were prone to drift and offered limited diagnostics,causing occasional aborted starts due to”bad”sensor readings.They upgraded to a Mark VIe system,deploying IS215ACLEH1Amodules for all critical analog sensing.

The impact was twofold.First,the modules’superior accuracy and stability eliminated spurious sensor alarms that had previously caused unnecessary start-up holds.Second,the advanced diagnostics provided clear,actionable information.For example,when a fuel gas pressure transmitter began to fail intermittently,the module logged specific”signal instability”alerts rather than a generic”bad value”alarm.Maintenance crews were dispatched with the precise diagnosis,replaced the faulty transmitter during a short offline window,and avoided what would have likely escalated into a forced outage during a high-demand period.The plant manager reported a 30%reduction in start-up failures and a significant decrease in troubleshooting time for sensor-related issues,attributing these gains directly to the improved performance and intelligence of the new I/O hardware,including the IS215ACLEH1A.

Related Product Combination Solutions

IS215UCVEH2A:A Mark VIe controller module(Unified Control Vector).This is the main processor that runs the control application,relying on the analog data provided by the IS215ACLEH1A.

IS200/IS215 Series I/O Terminal Boards(e.g.,IS200TBAIH1C):These are the physical terminal boards that provide screw terminals for field wiring.They connect via ribbon cables to the IS215ACLEH1Amodule,which houses the actual signal conditioning electronics.

ICMHor CMM(Communications Module):Modules that handle network communication(Ethernet,Genius,etc.)for the control rack,allowing the data from the IS215ACLEH1Ato be shared across the system.

ToolboxST Software:The essential engineering environment for configuring the IS215ACLEH1A(setting channel types,ranges,alarms),diagnosing faults,and integrating its data into the control application logic.

Mark VIe System Power Supplies:Provide the clean,regulated DC power required by all modules in the rack,including the sensitive analog circuitry of the IS215ACLEH1A.

Installation,Maintenance,and Full-Cycle Support

Installation of the IS215ACLEH1Ais a systematic process within the Mark VIe rack.It involves seating the module firmly in its designated slot,ensuring all locking levers are engaged,and connecting the appropriate ribbon cables to its mating terminal boards.Prior to power-up,the module must be correctly configured within the ToolboxST project—defining each channel’s sensor type,engineering units,scaling,and alarm setpoints.Field wiring should be checked for proper shielding and grounding to maximize signal integrity.

Maintenance is predominantly software-driven and predictive.Engineers should regularly review the diagnostic pages in ToolboxST for any channels reporting marginal health or intermittent faults.The modules themselves are not field-repairable;the standard practice is replacement.Having a pre-configured spare IS215ACLEH1Aon site is a key aspect of high-availability strategies.The hot-swap capability of the Mark VIe system(when architected for it)allows a faulty module to be replaced without taking the entire turbine offline,though this requires careful procedural adherence.

We provide complete lifecycle support for the GE IS215ACLEH1Aand the Mark VIe platform.From initial system design and module selection support to supplying guaranteed-functional new or refurbished units,we are your partner in maintaining control system integrity.Our technical team can assist with configuration,troubleshooting complex signal issues,and planning for obsolescence.We are committed to ensuring your turbine’s control system—the foundation of its performance and reliability—operates flawlessly.

Contact us for Mark VIe system diagnostics,to source guaranteed I/O modules,or to discuss a control system upgrade pathway.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: