Product Overview

The KOKUSAI SMPCONT-A3B is a dedicated process control system developed by KOKUSAI Electric Corporation(now fully integrated into SCREEN Semiconductor Solutions,part of Japan’s SCREEN Holdings)for managing vertical batch thermal processing equipment—primarily Low-Pressure Chemical Vapor Deposition(LPCVD),oxidation,and diffusion furnaces used in semiconductor manufacturing.

Designed as the central brain of KOKUSAI’s SMP(Single Module Platform)or batch furnace systems(e.g.,Kokusai DRYTEC,CENTURA-compatible platforms),the SMPCONT-A3B integrates real-time process control,safety interlocks,recipe execution,and factory host communication into a single industrial-grade enclosure.It coordinates critical subsystems including:

Multi-zone resistance or RF heating with±0.5°C precision

Boat elevator and wafer handling mechanics

Mass Flow Controllers(MFCs)for process gases(e.g.,SiH₄,NH₃,O₂,N₂)

Vacuum and pressure regulation(via APC valves)

Exhaust and abatement interface

Unlike general-purpose PLCs,the SMPCONT-A3B runs a proprietary real-time operating system optimized for semiconductor thermal processes,featuring pre-certified safety logic,automatic fault recovery,and SECS-II/GEM compliance out of the box—enabling seamless integration into 300mm fabs using EAP(Equipment Automation Program)and MES(Manufacturing Execution System)platforms like Applied Materials’FactoryWorks or PDF Solutions Exensio.

The“A3B”designation typically indicates a specific hardware revision with enhanced I/O capacity,updated communication interfaces,or support for newer gas chemistries compared to earlier A1/A2 variants.

Technical Specifications

Parameter Value

Manufacturer KOKUSAI Electric/SCREEN Semiconductor Solutions

Model SMPCONT-A3B

System Type Dedicated Semiconductor Furnace Controller

Target Equipment Vertical batch LPCVD,Oxidation,Diffusion furnaces(e.g.,SMP series)

Control Functions Temperature ramp/soak,gas sequencing,pressure control,boat motion,safety interlocks

Process Zones Up to 5 independent heater zones(typical)

I/O Capacity Expandable via remote I/O racks(digital/analog/specialty modules)

Host Communication SECS-I(RS-232),SECS-II over HSMS(Ethernet),GEM 300-compliant

Operator Interface Integrated touchscreen HMI or external display(VGA/serial)

Programming Proprietary recipe language+ladder logic(via engineering terminal)

Redundancy Optional dual power supplies;no full controller redundancy

Mounting 19″industrial rack or cabinet-mounted

Operating Environment Cleanroom compatible(Class 1000 or better),15–30°C

Certifications CE,UL 61010-1,SEMI S2/S8 compliant

Legacy Status Discontinued but actively supported in mature fabs(≤28nm nodes)

⚠️Note:The SMPCONT-A3B is not user-programmable like a standard PLC.Recipes and process parameters are configured via dedicated engineering software(e.g.,Kokusai Process Manager)and require factory-trained personnel for modification.

Main Features and Advantages

Semiconductor-Grade Reliability:Designed for 24/7 operation in high-purity environments with<0.1%process abort rate.

Regulatory Compliance:Fully compliant with SEMI S2(safety),S8(ergonomics),and EHS standards for toxic/corrosive gas handling.

Advanced Recipe Control:Supports multi-step thermal profiles,gas pulse sequences,and in-situ endpoint detection(when paired with sensors).

Factory Integration Ready:Native SECS/GEM enables automatic lot dispatch,alarm reporting,and data collection for SPC.

Proven Field Base:Thousands of units deployed globally—extensive spare parts and service knowledge available.

Application Field

The SMPCONT-A3B is found in:

Memory&Logic Fabs:Poly-Si deposition,ONO stack formation,gate oxidation.

Power Device Manufacturing:High-temp annealing and diffusion for SiC/GaN.

MEMS&Image Sensors:Sacrificial layer deposition and release etch steps.

Legacy 200mm Lines:Where tool replacement is cost-prohibitive.

R&D Pilot Lines:For process development due to flexible recipe structure.

It remains a workhorse in mature technology nodes(≥90 nm),though newer installations typically use SCREEN’s next-gen controllers(e.g.,SPMC-EX series).

Related Products

KOKUSAI SMP Furnace Series:e.g.,SMP-300,SMP-500

Gas Box Assemblies:Integrated MFC manifolds with VCR fittings

Boat Elevator Mechanism:Quartz or SiC wafer carriers with lift control

SPMC-EX:Successor platform with Windows Embedded,OPC UA,and cloud connectivity

HOSTLINK Software:For SECS/GEM configuration and logging

Remote I/O Modules:e.g.,analog input cards for thermocouples,RTDs

Installation and Maintenance

Installation Considerations:

Must be installed in a temperature-controlled,ESD-safe equipment room adjacent to the furnace.

Requires dedicated UPS and filtered 208/240 VAC power.

All field wiring must meet SEMI F47 voltage sag immunity standards.

Grounding resistance<1Ωto prevent noise in thermocouple signals.

Maintenance Best Practices:

Perform monthly backup of all recipes and calibration data.

Monitor heater zone drift and recalibrate thermocouples quarterly.

Replace backup batteries on memory modules every 2 years.

Use only KOKUSAI-approved firmware patches—unauthorized updates may void safety certifications.

Product Guarantee

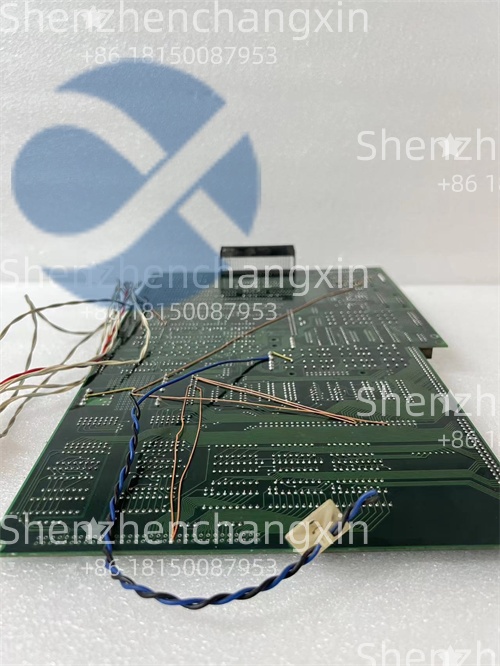

Every KOKUSAI SMPCONT-A3B we supply is fully tested and refurbished to OEM specifications by certified technicians with direct experience in semiconductor equipment.Each unit undergoes:

Full power-on self-test(POST)

Thermocouple simulation and heater loop validation

SECS/GEM communication handshake test

Recipe load/run verification

Safety interlock and EMO(Emergency Off)check

We provide a 12-month warranty,complete documentation(including block diagrams and I/O maps),and optional on-site commissioning support.While no longer in production,the SMPCONT-A3B remains a critical asset in many fabs—and we ensure it performs reliably until your migration plan is ready.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: