Product Overview

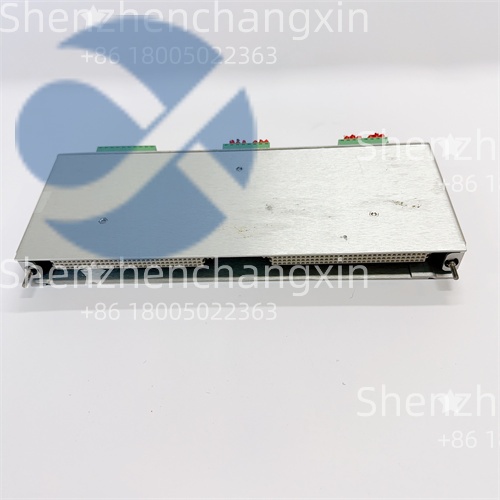

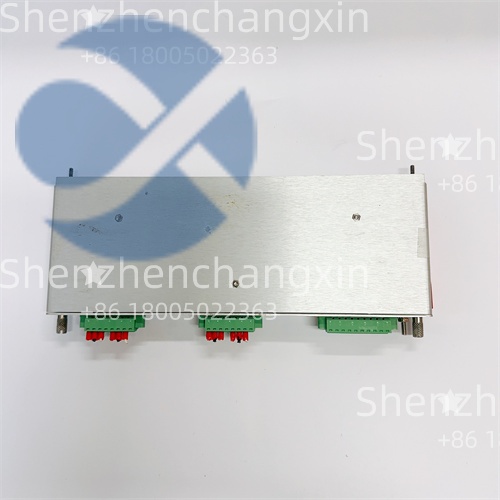

The BENTLY 1900/27represents a sophisticated loop-powered vibration transmitter engineered for continuous monitoring of rotating machinery in industrial environments.This compact yet powerful transmitter converts mechanical vibration signals into standardized 4-20mA output signals,enabling seamless integration with PLCs,DCS systems,and condition monitoring platforms.The 1900/27is particularly valuable in applications requiring reliable vibration trending and early fault detection,where continuous monitoring of pump,motor,fan,and compressor vibration levels helps prevent unexpected downtime and equipment damage.Its robust industrial design ensures accurate performance in challenging environments with temperature variations,moisture,and electrical interference.

Designed with installation flexibility in mind,the BENTLY 1900/27features a compact form factor that facilitates mounting in space-constrained locations while maintaining measurement accuracy.The transmitter’s loop-powered operation eliminates the need for separate power wiring,significantly reducing installation time and complexity.Advanced signal processing circuitry provides true RMS vibration velocity measurement,delivering accurate representation of overall machine condition regardless of waveform characteristics.The 1900/27’s wide frequency response range captures both low-frequency imbalance and misalignment conditions as well as high-frequency bearing and gear mesh frequencies,providing comprehensive machinery health assessment.Its durable stainless steel construction and environmental sealing make it suitable for installation in harsh industrial environments where reliability is paramount.

Technical Specifications

Parameter Name

Parameter Value

Product Model

1900/27

Manufacturer

Bently Nevada

Product Type

Loop-Powered Vibration Transmitter

Output Signal

4-20mA two-wire

Power Supply

12-30V DC loop powered

Measuring Range

0-2 in/sec(0-50 mm/s)peak

Frequency Response

4.5 Hz to 1000 Hz(±3dB)

Accuracy

±2%of full scale

Linearity

±1%of full scale

Operating Temperature

-40°C to+85°C

Storage Temperature

-50°C to+100°C

Housing Material

316 Stainless Steel

Electrical Connection

1/2″NPT conduit entry

Process Connection

1/4″-28 UNF mounting thread

Weight

0.3 kg(0.66 lbs)

Protection Rating

IP67

Hazardous Area Certification

ATEX,IECEx

Response Time

1 second to 90%of final value

Damping

Critically damped for machinery applications

Main Features and Advantages

Measurement precision:The BENTLY 1900/27delivers exceptional measurement accuracy through advanced seismic mass technology and precision signal conditioning.The transmitter’s velocity-based measurement provides true RMS values that accurately represent machine vibration severity,enabling reliable trend analysis and alarm setting.Wide frequency response captures both low-frequency components indicative of imbalance and misalignment,and high-frequency energy associated with bearing defects and gear issues.The unit’s critically damped design ensures accurate measurement without resonance effects in the operating frequency range,providing stable readings during machine speed changes.

Installation flexibility:Compact design and multiple mounting options facilitate installation in confined spaces.The 1900/27’s loop-powered operation simplifies wiring by combining power and signal transmission in a single two-wire circuit,reducing installation cost and complexity.Standard 1/4″-28 UNF mounting thread compatible with most industrial vibration sensors allows easy integration into existing monitoring points.The transmitter’s robust stainless steel housing withstands corrosive environments and mechanical impact,ensuring long-term reliability in demanding applications.

Reliability engineering:Hermetically sealed housing provides complete protection against moisture,dust,and chemical exposure.The BENTLY 1900/27’s industrial-grade components and manufacturing processes ensure stable performance over extended operational periods.Built-in lightning and surge protection safeguards against electrical transients common in industrial environments.The transmitter’s wide operating temperature range(-40°C to+85°C)maintains accuracy in extreme conditions,from arctic applications to high-temperature process areas.

The BENTLY 1900/27vibration transmitter delivers reliable machinery monitoring for predictive maintenance programs.With its robust construction and accurate measurement capabilities,it provides early warning of developing mechanical problems while withstanding the challenging conditions of industrial environments.

Application Field

The BENTLY 1900/27finds extensive application in industries where continuous vibration monitoring is essential for equipment reliability and preventive maintenance.In pumping systems for water treatment,chemical processing,and oil&gas applications,the transmitter monitors centrifugal and positive displacement pumps,detecting issues such as impeller wear,bearing degradation,and cavitation.The transmitter’s 4-20mA output seamlessly integrates with existing control systems,enabling continuous monitoring without additional hardware.In power generation facilities,the 1900/27monitors critical auxiliary equipment including cooling tower fans,boiler feed pumps,and air compressor systems,providing early warning of mechanical degradation before failure occurs.

Manufacturing industries utilize the BENTLY 1900/27for monitoring production equipment where unexpected downtime directly impacts productivity.In paper mills,the transmitter tracks vibration levels on critical machines including refiners,pumps,and vacuum systems.The unit’s IP67 rating protects against water ingress during washdown procedures common in pulp and paper processing.In mining and mineral processing,the robust construction withstands the high vibration and dust levels encountered in crusher,conveyor,and mill applications.The transmitter’s hazardous area certifications(ATEX,IECEx)enable installation in potentially explosive atmospheres found in chemical plants and refineries.

Related Products

1900/65|Enhanced version with display

1900/53|Basic vibration transmitter

3300 XL|Proximity transducer systems

3500 Series|Machinery protection system

Velocity sensors|Seismic vibration transducers

Mounting accessories|Magnetic bases and adapter studs

Installation and Configuration

Pre-installation preparation:Before installing the BENTLY 1900/27,verify mounting surface suitability and ensure proper grounding practices.Check that the measurement range matches the expected vibration levels of the monitored equipment.Have appropriate calibration certificates and documentation ready for commissioning.

Configuration guidelines:Mounting orientation should follow manufacturer recommendations for optimal measurement accuracy.Cable routing should avoid areas with excessive movement or high temperatures.Calibration should be verified against known vibration sources to ensure measurement accuracy.For hazardous area installations,verify that installation complies with certification requirements and applicable safety standards.

Product Guarantee

We guarantee that every BENTLY 1900/27vibration transmitter is a genuine Bently Nevada product manufactured to the highest industry standards.Our technical support team provides comprehensive assistance with selection,installation,and calibration.All transmitters undergo rigorous testing to verify they meet original performance specifications for reliable operation in industrial monitoring applications.We stand behind our products with full technical support and commitment to customer satisfaction.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: