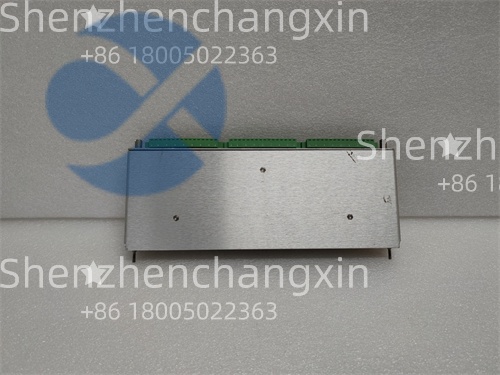

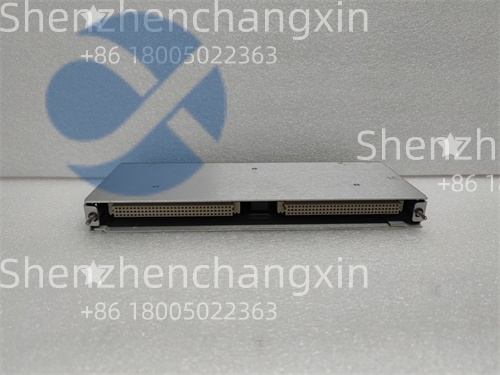

Product Overview

The BENTLY 132417-01is a specialized monitoring module manufactured by Bently Nevada(now part of Baker Hughes),designed specifically for reciprocating compressor applications.This 4-channel instrument serves as a 3500/70M Reciprocating Pulse Speed Monitor,providing critical protection and monitoring functions for reciprocating compressors by continuously monitoring compressor crankcase and crosshead vibration

.

Engineered for maximum reliability in demanding industrial environments,the BENTLY 132417-01features advanced signal processing capabilities and comprehensive protection mechanisms.The module accepts inputs from seismic sensors,processes signals to generate vibration measurements,and compares these measurements against user-programmable alarm setpoints to drive protective actions

.

Technical Specifications

Product Model|BENTLY 132417-01

Manufacturer|Bently Nevada(Baker Hughes)

Product Type|4-Channel Monitoring Module

System Compatibility|Bently Nevada 3500 Series

Number of Channels|4 channels

Monitoring Type|Reciprocating Pulse Speed

Input Type|Seismic sensors

Output Type|Programmable alarms

Configuration|Channel pairs(1-2 and 3-4)

Functions Supported|Pulse acceleration,Acceleration 2,Reciprocating speed,Low-frequency reciprocating speed

Operating Temperature|Industrial grade range

Power Supply|24V DC(from backplane)

Certifications|UL,cULus,CE,ATEX

Main Features and Advantages

Advanced Reciprocating Monitoring:The BENTLY 132417-01provides specialized monitoring capabilities for reciprocating compressors,a critical application in industrial processes.The module’s four channels can be programmed in pairs to perform different monitoring functions simultaneously,offering flexibility in monitoring strategy.For example,channels 1-2 can perform one function while channels 3-4 perform another or the same function

.

Comprehensive Protection Functions:The module supports multiple monitoring functions including pulse acceleration,acceleration 2,reciprocating speed,and low-frequency reciprocating speed.Each channel processes input signals to produce various parameters called static values,with configurable alarm and danger setpoints for each active static value.The BENTLY 132417-01’s primary purpose is to provide mechanical protection for reciprocating compressors through continuous parameter comparison against configured alarm setpoints

.

Flexible Configuration Options:The BENTLY 132417-01offers flexible configuration through Bently Nevada’s 3500 framework configuration software.Each channel can be independently programmed to perform specific monitoring functions,and channels can be grouped in pairs to execute multiple functions simultaneously.This flexibility allows for customized monitoring strategies based on specific compressor requirements and operational conditions

.

Application Field

The BENTLY 132417-01finds extensive application in industrial sectors utilizing reciprocating compressors,particularly in oil and gas processing,chemical manufacturing,and power generation facilities.The module is specifically designed for monitoring reciprocating compressor crankcase and crosshead vibration,providing essential data for predictive maintenance and operational optimization

.

In process industries,the BENTLY 132417-01serves critical functions in compressor protection systems,where it monitors vibration patterns to detect early signs of mechanical issues such as bearing wear,valve problems,or piston rod failures.The module’s ability to monitor both pulse acceleration and reciprocating speed makes it particularly valuable for comprehensive compressor health assessment

.

Related Products

Bently Nevada 3500 Series-Complete monitoring system framework

3500/15 Power Supply-System power modules

3500/22M Framework Interface Module-System interface

3500/25 Keyphasor Module-Keyphasor signal processing

3500/32 Relay Module-Output relay modules

3500/42M Vibration Monitor-Vibration monitoring modules

3500/60 Temperature Monitor-Temperature monitoring modules

Installation and Maintenance

Pre-installation Preparation:Before installing the BENTLY 132417-01,verify compatibility with the existing 3500 series framework and ensure proper slot allocation.Check seismic sensor specifications and ensure proper wiring connections.Prepare appropriate configuration tools and software for commissioning the module

.

Maintenance Recommendations:Regular maintenance includes visual inspection for signs of damage or overheating,verification of monitoring functionality using diagnostic tools,and monitoring of LED status indicators.Periodically check wiring connections for tightness and ensure adequate ventilation around the module.Keep firmware updated to the latest compatible version and maintain configuration backups

.

Product Guarantee

We guarantee that all BENTLY 132417-01monitoring modules are genuine Bently Nevada products manufactured to original specifications.Our quality assurance process includes comprehensive testing to verify monitoring performance and protection functionality.We provide complete technical support for configuration,installation,and troubleshooting,backed by our team of automation experts with extensive experience in industrial monitoring systems

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: