Description

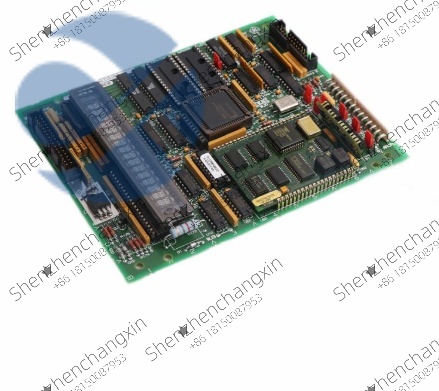

The GE DS200SLCCG1AFG is a Slot Logic Control Card(SLCC)used in GE’s Mark V and early Mark VI industrial turbine control systems—primarily for gas turbines,steam turbines,and combined-cycle power plants.This board serves as the primary I/O interface and local processing module within a VME-based control rack,acting as the”hands and eyes”of the turbine controller by managing discrete inputs/outputs,analog signals,and communication with terminal boards.

Mounted in a specific slot of the Mark V/VI core control chassis,the DS200SLCCG1AFG:

Scans field devices(limit switches,solenoids,pressure switches)

Drives output relays and contactors

Interfaces with TCQA,TCQB,or PTBA terminal boards via ribbon cables

Provides health monitoring of I/O circuits(open-wire,short-circuit detection)

Communicates with the main controller(e.g.,CSPX or TCEA)over the VME backplane

The suffix“AFG”denotes a specific hardware revision,firmware compatibility level,and I/O configuration optimized for certain turbine frames(e.g.,Frame 6B,7EA)and application types(simple cycle vs.cogeneration).

Note:The SLCC is not a standalone CPU—it operates under the supervision of the main turbine protection and sequencing processor but handles real-time I/O scanning independently to reduce system latency.

Application Scenarios

At a peaking power plant in Arizona,a Frame 7FA gas turbine experienced intermittent“Loss of Flame”trips during hot starts.Diagnostics traced the issue to degraded opto-isolators on the DS200SLCCG1AFG card,causing false flame scanner signal dropout.After replacing the SLCC with a validated DS200SLCCG1AFG,the turbine achieved 100%start reliability over 200+cycles—even at 52°C ambient—restoring grid ancillary service revenue and avoiding$400k/month in performance penalties.

Parameter

Main Parameters Value/Description

Product Model DS200SLCCG1AFG

Manufacturer GE Power/GE Vernova(Legacy Distributed Control Systems)

Product Category Turbine I/O Control Board–Mark V/Mark VI Platform

Compatible Systems Mark V,Mark VI(non-e),TMR and Simplex variants

I/O Capacity•Up to 32 digital inputs(24 VDC)

•Up to 32 digital outputs(relay or solid-state)

•Optional analog I/O via daughter cards

Terminal Board Interface Ribbon cable to TCQA,TCQB,PTBA,or DTBA boards

Backplane Interface VME64(32-bit data bus)to main controller

Diagnostics LED status per channel,open-wire detection,fuse monitoring

Power Supply+5 VDC,±12 VDC from system backplane

Operating Temperature 0°C to+60°C

Mounting VME card cage(6U form factor)

Redundancy Supports TMR(Triple Modular Redundant)voting in critical applications

Technical Principles and Innovative Values

Innovation Point 1:Deterministic I/O Scanning

The DS200SLCCG1AFG scans all I/O every 10–25 ms—ensuring rapid response to safety-critical signals like overspeed,loss of lube oil,or fire detection.

Innovation Point 2:Field-Proven Isolation Architecture

Each I/O channel uses opto-couplers and transient suppressors rated for 5 kV isolation—protecting the control system from ground faults and lightning-induced surges in harsh plant environments.

Innovation Point 3:Plug-Compatible Modularity

Enables hot-swap(in non-TMR systems)and rapid replacement without rewiring—critical for minimizing outage time during forced outages.

Innovation Point 4:Integrated Self-Test(BIT)

Built-in diagnostics verify I/O path integrity during power-up and runtime,reducing troubleshooting time from hours to minutes.

Application Cases and Industry Value

During a major overhaul at a refinery cogeneration facility in Louisiana,all DS200SLCCG1AFG cards in the Mark V-controlled steam turbine were proactively replaced as part of a 20-year life-extension program.Post-upgrade:

Forced outage rate dropped from 4.2%to 0.7%

SIL-2 compliance was maintained for emergency shutdown functions

Integration with new Proficy Historian enabled predictive maintenance on valve stroking

The project paid back in 14 months through avoided downtime and reduced maintenance labor.

Related Product Combination Solutions

Terminal Boards:

TCQA:Digital I/O termination

PTBA:Analog input(thermocouples,4–20 mA)

DTBA:High-speed pulse counting(speed probes)

Main Controller:CSPX(Mark V)or TCEA(Mark VI)

Rack&Backplane:VCMI or VCRC communications modules

Software:Mark V Toolbox,ToolboxST(for configuration&diagnostics)

Test Equipment:SLCC Simulator Rack for bench validation

Modern Migration Path:Mark VIe with PACSystems RX3i or Redundant PAC architecture

Spare Strategy:Keep matched sets(SLCC+terminal board)for rapid swap

Installation,Maintenance,and Full-Cycle Support

Installation Best Practices:

Power down control rack section(follow LOTO procedures)

Record DIP switch settings or EEPROM configuration before removal

Align card guides carefully—do not force into VME slot

Verify I/O mapping in Toolbox after replacement

Maintenance Recommendations:

Clean edge connectors annually with contact enhancer

Monitor I/O error counters via diagnostic logs

Replace backup battery on associated controller if>3 years old

Perform functional I/O test during every major outage

Every DS200SLCCG1AFG we supply is:

Fully tested on Mark V/VI simulator rack

Validated for I/O response time and isolation integrity

Inspected for capacitor aging,trace corrosion,and connector wear

Supplied with test report and compatibility verification

We offer a 12-month warranty,legacy software support,and expert engineering assistance for integration or failure analysis.Our inventory includes both New Old Stock(NOS)and refurbished-tested units—all fully traceable to GE documentation.

Contact us for a customized solution—whether you’re maintaining legacy Mark V/VI turbines,executing a reliability upgrade,or securing mission-critical spares.With the GE DS200SLCCG1AFG,you ensure continued safe,compliant,and efficient operation of your turbine assets for years to come.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: