Product Overview

The GE IC670MDL930K is an 8-channel thermocouple input module designed for the GE Series 90 Micro programmable logic controller(PLC)platform.It provides high-precision temperature measurement by directly interfacing with a wide range of industry-standard thermocouple types—including J,K,T,E,R,S,and B—making it ideal for applications requiring accurate thermal monitoring in processes such as heating,drying,curing,and combustion control.Each channel on the GE IC670MDL930K features built-in cold junction compensation(CJC),signal conditioning,and open-circuit(burnout)detection to ensure reliable data acquisition even under adverse field conditions.

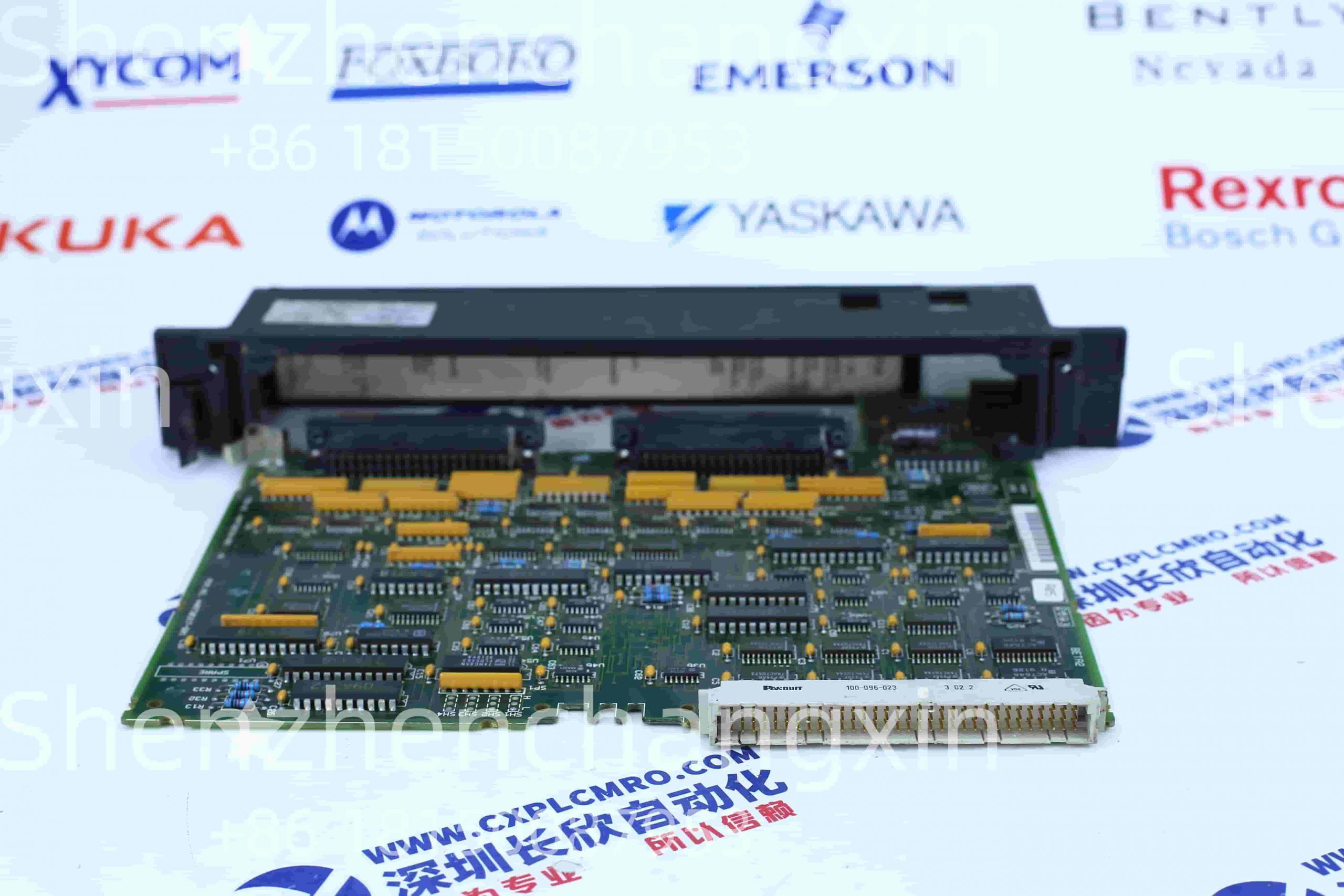

Engineered for seamless integration into compact control panels,the IC670MDL930K mounts directly onto Series 90 Micro baseplates like the IC670CHS101,occupying a single module slot while delivering eight independent temperature inputs.This high-density design reduces panel space requirements and eliminates the need for external signal conditioners or transmitters.The module communicates digitized temperature values to the CPU via the internal backplane bus,enabling real-time control logic decisions based on thermal profiles.Although part of GE’s legacy automation portfolio(now maintained under Emerson),the IC670MDL930K remains widely used in industries where proven reliability,ease of maintenance,and compatibility with existing infrastructure outweigh the need for newer architectures.

Technical Specifications

Product Model|IC670MDL930K

Manufacturer|General Electric(GE)/Emerson

Product Type|Thermocouple Input Module

Number of Channels|8 differential inputs

Supported Thermocouple Types|J,K,T,E,R,S,B(software-selectable per channel)

Cold Junction Compensation|Built-in,automatic(via onboard sensor)

Input Impedance|>1 MΩ

Resolution|16-bit A/D conversion

Accuracy|±0.25%of span typical(varies by type and range)

Burnout Detection|Yes–configurable(upscale/downscale on open circuit)

Update Rate|~100 ms per channel(typical)

Isolation|Optical isolation between field and logic sides(500 VDC)

Indicators|Single status LED(module OK);diagnostics via software

Mounting|Single-slot on Series 90 Micro baseplate(e.g.,IC670CHS101)

Operating Temperature|0°C to+60°C

Power Consumption|~2.0W from backplane

Certifications|CE,UL,CSA

Main Features and Advantages

Multi-type thermocouple flexibility:The IC670MDL930K supports all major thermocouple standards in a single module,allowing mixed-sensor installations without hardware changes.Engineers can configure each channel independently via configuration software(e.g.,Logicmaster 90),enabling diverse temperature zones—such as a K-type in a furnace and a T-type in a refrigeration unit—to coexist on one I/O card.

Advanced diagnostics for predictive reliability:Built-in open-circuit detection alerts the PLC when a thermocouple wire breaks or disconnects—a common failure mode in high-vibration or high-temperature environments.The IC670MDL930K can be configured to drive the output upscale(+10 mV)or downscale(–10 mV)upon burnout,ensuring fail-safe logic responses(e.g.,triggering a shutdown or alarm).

High noise immunity and precision:With optical isolation and differential inputs,the IC670MDL930K rejects ground loops and electromagnetic interference that could distort low-level thermocouple signals(typically<50 mV).Combined with 16-bit resolution and factory calibration,this ensures accurate temperature readings critical for product quality and safety compliance in regulated industries.

Compact integration with Series 90 Micro systems:By plugging directly into the IC670CHS101 baseplate alongside CPUs and other I/O,the IC670MDL930K eliminates external wiring and signal converters.This simplifies panel design,reduces installation time,and minimizes points of failure—key advantages in OEM machinery and retrofit projects where space and reliability are constrained.

Application Field

The IC670MDL930K is commonly deployed in thermal process applications across multiple sectors.In food and beverage processing,it monitors cooking,pasteurization,and chilling temperatures using K-or T-type sensors to meet HACCP and FDA requirements.In industrial ovens and dryers(e.g.,paint curing,textile finishing),the module tracks multiple zone temperatures to maintain uniform heat distribution and prevent product defects.

In boiler and steam systems,the IC670MDL930K reads flue gas,feedwater,and exhaust temperatures for efficiency optimization and safety interlocks.Similarly,in plastic injection molding machines,it controls barrel and mold temperatures with tight tolerances to ensure part consistency.The module is also used in environmental test chambers,laboratory equipment,and HVAC reheat coils where precise thermal regulation is essential.Its compatibility with legacy GE systems makes it a go-to solution for modernizing older temperature control panels without replacing entire PLC infrastructures.

Related Products

IC670CHS101:Baseplate for mounting IC670MDL930K and other Series 90 Micro modules

IC670CPU101:CPU module for Series 90 Micro systems

IC670MDL931K:4-channel RTD input module(for Pt100,Ni120,etc.)

IC670MDL644:16-point discrete input module for digital signals

IC670MDL740:16-point transistor sinking output module

IC670PWR101:24V DC power supply module

IC670ACC001:Removable terminal block kit for quick maintenance

Logicmaster 90:Configuration and programming software for Series 90 Micro PLCs

Installation and Maintenance

Pre-installation preparation:Use twisted-pair,shielded thermocouple extension wire rated for the specific sensor type(e.g.,Type K wire for K sensors).Ground the shield at the controller end only to avoid ground loops.Ensure the IC670MDL930K is fully seated on the baseplate and that terminal screws are torqued to specification.Avoid routing thermocouple wires parallel to AC power lines;if unavoidable,maintain separation>30 cm or use conduit.

Maintenance recommendations:Periodically inspect terminals for oxidation or loosening,especially in high-humidity environments.Verify cold junction compensation accuracy during calibration checks by comparing ambient temperature at the module terminals with the CJC reading in software.Use the burnout detection feature in your PLC logic to trigger maintenance alerts before process deviations occur.When replacing the module,retain configuration settings or document channel assignments to ensure correct re-commissioning.Store spares in anti-static,dry packaging away from magnetic fields.

Product Guarantee

Every IC670MDL930K we provide is 100%authentic and functionally tested on a live Series 90 Micro system,verifying thermocouple response,cold junction compensation,and open-circuit diagnostics across multiple sensor types.We guarantee compatibility with GE’s legacy architecture and offer full technical support for integration and troubleshooting.Backed by a 12-month warranty and decades of industrial automation expertise,our IC670MDL930K modules deliver trusted performance for mission-critical temperature monitoring—ensuring your processes remain safe,compliant,and efficient.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: