Product Overview

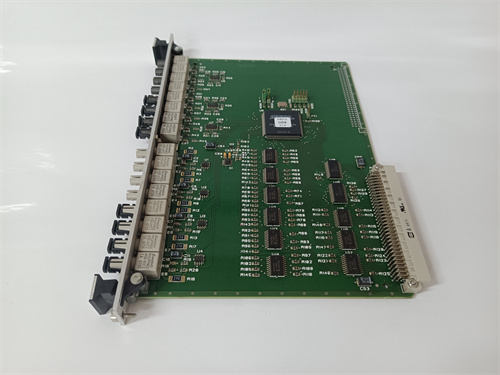

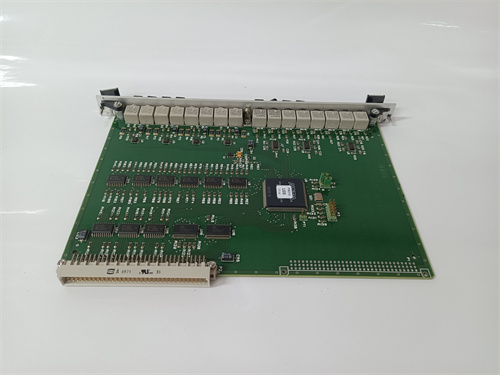

The ABB PIB310 3BHB0190 is a high-performance PROFIBUS DP communication interface module designed for seamless integration into ABB’s AC 800M programmable logic controller(PLC)platform.As part of ABB’s widely deployed System 800xA architecture,the ABB PIB310 3BHB0190 enables deterministic data exchange between the AC 800M CPU and distributed I/O stations,remote drives,valve terminals,and third-party field devices across PROFIBUS DP networks.This compact,DIN-rail mountable module supports both master and slave operating modes,making it ideal for centralized control systems as well as peer-to-peer coordination in complex automation topologies.

Engineered for reliability in demanding industrial settings—such as oil&gas refineries,chemical plants,power generation facilities,and mining operations—the ABB PIB310 3BHB0190 features robust galvanic isolation,conformal-coated circuitry,and compliance with IEC 61000-4 electromagnetic compatibility standards.It operates at standard PROFIBUS baud rates up to 12 Mbps and supports cyclic data exchange with diagnostics,parameterization,and acyclic messaging per the PROFIBUS DP-V1 specification.The ABB PIB310 3BHB0190 plugs directly into the I/O bus backplane of AC 800M racks,drawing power and synchronization from the controller while offloading communication tasks from the main CPU—thereby optimizing scan cycle performance and system responsiveness.With its long lifecycle support and backward compatibility,this module remains a cornerstone in both greenfield installations and brownfield modernization projects leveraging ABB’s integrated automation ecosystem.

Technical Specifications

Parameter Name Parameter Value

Product Model PIB310 3BHB0190

Manufacturer ABB

Product Type PROFIBUS DP Communication Interface Module

Communication Protocol PROFIBUS DP(DP-V0 and DP-V1 compliant)

Baud Rate 9.6 kbps to 12 Mbps(auto-configurable)

Electrical Isolation 500 V RMS(fieldbus to backplane)

Bus Interface RS-485(9-pin D-sub connector,isolated)

Max.Slave Devices Up to 126 per segment(with repeaters)

Power Consumption Approx.2.5 W(from I/O bus)

Operating Temperature 0°C to+60°C

Dimensions(W×H×D)35 mm×140 mm×110 mm

Mounting DIN rail(35 mm)or rack-mounted via AC 800M I/O base

Certifications CE,UL,cUL,IEC 61131-2,EMC Directive 2014/30/EU

Main Features and Advantages

Seamless integration with ABB AC 800M and System 800xA:The ABB PIB310 3BHB0190 is natively supported in ABB’s Automation Builder engineering suite,enabling drag-and-drop configuration,automatic GSD file handling,and real-time diagnostics within the same development environment used for logic programming.This tight integration reduces engineering time and eliminates protocol translation layers that can introduce latency or data loss.

High availability through redundancy and diagnostics:In redundant AC 800M High Integrity(HI)systems,dual PIB310 3BHB0190 modules can be configured for hot-standby operation,ensuring uninterrupted fieldbus communication during controller switchover.Built-in LED indicators show link status,data activity,and fault conditions,while detailed diagnostic buffers report device-specific errors such as short circuits,missing slaves,or baud rate mismatches—accelerating troubleshooting.

Robust design for electrically noisy environments:The ABB PIB310 3BHB0190 employs transformer-coupled RS-485 transceivers and opto-isolated signal paths to suppress ground loops and high-frequency interference common near VFDs,switchgear,or welding equipment.Its conformal coating protects against humidity,dust,and corrosive atmospheres,meeting IP20 requirements for panel-mounted use.

Flexible topology and interoperability:Supporting both master and slave roles,the ABB PIB310 3BHB0190 can connect to a wide range of PROFIBUS-compliant devices—including Siemens ET 200,Festo valve terminals,SEW drives,and Pepperl+Fuchs I/O blocks—enabling hybrid architectures without gateway hardware.Its support for DP-V1 acyclic services allows parameter upload/download during runtime,facilitating predictive maintenance and remote commissioning.

Long-term lifecycle and migration readiness:Despite newer Ethernet-based alternatives,the ABB PIB310 3BHB0190 remains actively supported by ABB with firmware updates and spare parts availability,ensuring continuity for installed bases.It also serves as a cost-effective bridge during phased migrations from legacy fieldbuses to ABB Ability™-enabled Ethernet networks.

Application Field

The ABB PIB310 3BHB0190 is extensively deployed in process and discrete industries where reliable,real-time fieldbus communication is essential for operational efficiency and safety.In oil&gas upstream and midstream facilities,it connects AC 800M controllers to remote wellhead monitoring panels,separator level transmitters,and compressor drive systems over extended PROFIBUS segments—often spanning several kilometers with fiber-optic repeaters.In chemical and pharmaceutical plants,the ABB PIB310 3BHB0190 interfaces with modular skids,batch reactors,and CIP(Clean-in-Place)units,enabling synchronized recipe execution and traceable data logging compliant with FDA 21 CFR Part 11.

Power generation applications leverage the ABB PIB310 3BHB0190 to integrate boiler soot blowers,turbine auxiliary pumps,and switchyard motor control centers into centralized DCS architectures.Mining and minerals processing plants use it to network conveyor belt drives,crusher motors,and flotation cell sensors across rugged terrain where Ethernet cabling is impractical.Municipal water and wastewater treatment facilities rely on the ABB PIB310 3BHB0190 for distributed pump station control,linking PLCs to submersible level sensors and variable-speed pumps via intrinsically safe PROFIBUS PA segments(via DP/PA couplers).Even in automotive assembly lines,the module coordinates robotic weld cells and paint booths through standardized PROFIBUS networks.Across all these sectors,the ABB PIB310 3BHB0190 delivers proven interoperability,low-latency response,and decades-long service life—making it a trusted enabler of industrial automation resilience.

Related Products

PIB320:Enhanced PROFIBUS module with dual ports for ring redundancy

NDB310:DeviceNet communication interface for AC 800M

ETHx00 series:Ethernet/IP or Modbus TCP modules for modern AC 800M networks

CI854A:PROFIBUS DP/PA coupler for process instrumentation

AC 800M PM86x:CPU families compatible with PIB310 3BHB0190

TB510:Terminal base for PIB310 with removable wiring

3BHB019010R0101:Alternate firmware variant for specific GSD profiles

System 800xA:ABB’s integrated control platform hosting PIB310 configurations

Installation and Maintenance

Pre-installation preparation:Before installing the ABB PIB310 3BHB0190,verify compatibility with the target AC 800M CPU model and I/O base version.Ensure the PROFIBUS cable uses twisted-pair,shielded AWG 22 conductors with 120Ωcharacteristic impedance,and install 220Ωtermination resistors at both ends of the segment.Ground the cable shield at a single point near the controller to avoid ground loops.Confirm that the GSD file for the PIB310 3BHB0190 is loaded in Automation Builder prior to hardware configuration.

Maintenance recommendations:Periodically inspect the ABB PIB310 3BHB0190’s D-sub connector for corrosion or loose pins,especially in humid environments.Monitor diagnostic LEDs for blinking error patterns indicating bus faults.Use ABB’s Control Builder M or Asset Optimization tools to review communication error counters and slave health logs.During major outages,reseat the module to ensure solid backplane contact.For units exposed to frequent electrical transients,consider adding external surge protection on the fieldbus line.Refurbished PIB310 3BHB0190 modules should undergo full functional testing and firmware validation before deployment in critical processes.

Product Guarantee

The ABB PIB310 3BHB0190 is manufactured under ABB’s ISO 9001 and ISO 14001 certified quality systems,ensuring consistent performance and environmental compliance.ABB provides comprehensive lifecycle support,including technical documentation,firmware updates,and global spare parts availability.New and refurbished units undergo rigorous burn-in and functional verification before shipment.Customers benefit from ABB’s industry-leading warranty coverage—typically 18 months from date of shipment—covering defects in materials and workmanship.For mission-critical applications,extended service agreements and on-site support are available through ABB Ability™Care programs.This enduring commitment ensures that the ABB PIB310 3BHB0190 continues to deliver reliable,secure,and future-ready fieldbus connectivity across the global industrial landscape.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: