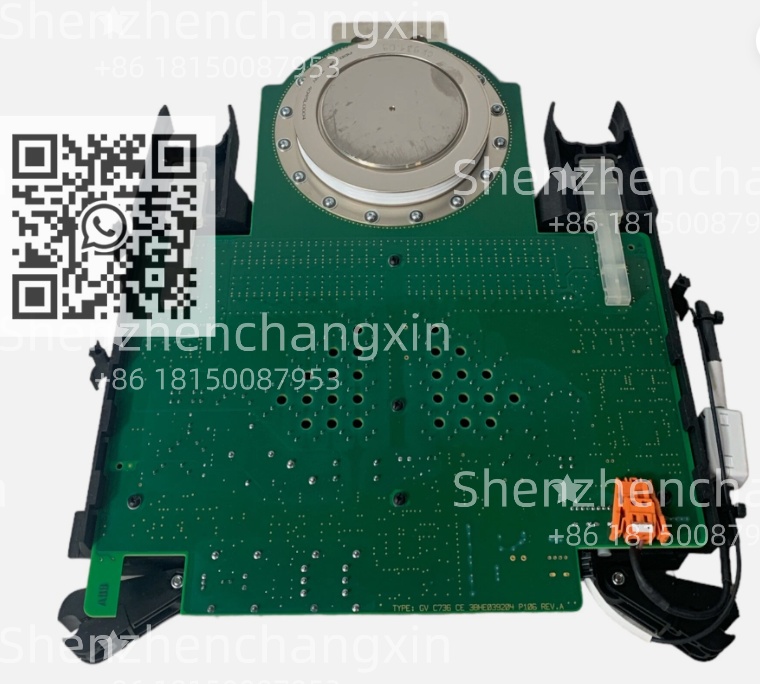

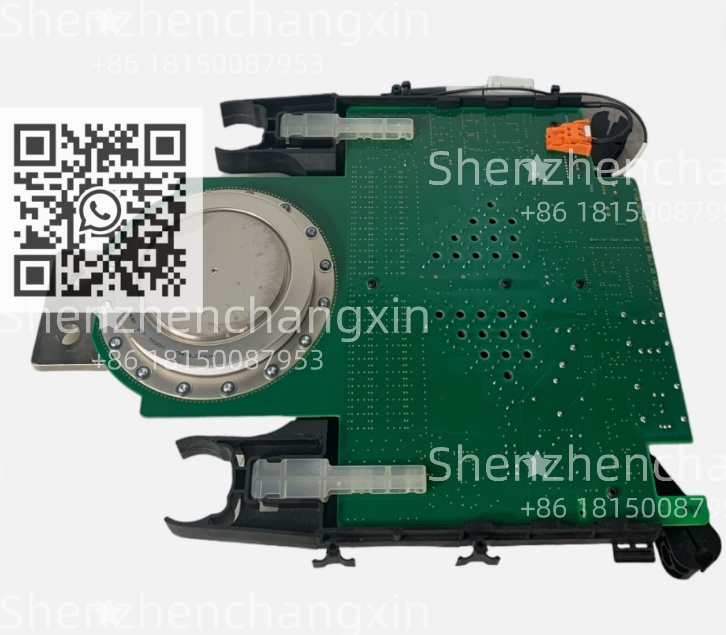

Description

Application Scenarios

In a large steel processing plant in Germany,the ABB 3BHB021400R0002drive control units were implemented to control high-power rolling mill motors requiring precise speed synchronization and torque regulation.The facility had been experiencing production inconsistencies due to variations in motor speed control during metal forming processes.After installing ABB 3BHB021400R0002controllers,the plant achieved speed regulation accuracy within 0.01%of setpoint,resulting in a 15%improvement in product dimensional consistency.The units’advanced thermal management system maintained stable operation even during peak production periods when ambient temperatures reached 45°C,while the built-in diagnostics provided early warning of potential issues before they affected production quality.

Parameter

Main Parameters

Value/Description

Product Model

ABB 3BHB021400R0002

Manufacturer

ABB

Product Type

Drive Control Unit

Compatible Systems

ACS 6000,ACS 8000 series

Rated Power

315-560kW(configurable)

Input Voltage

3300V AC,3-phase

Output Current

100-180A(application dependent)

Control Method

DTC(Direct Torque Control)

Processor

32-bit DSP with FPGA

Communication

PROFIBUS DP,Modbus TCP/IP

I/O Capability

16 digital I/O,8 analog I/O

Protection Class

IP00(cabinet mounted)

Cooling Method

Liquid cooling

Operating Temperature

0°C to+55°C

Storage Temperature

-40°C to+70°C

Isolation Voltage

4000V AC

Certifications

CE,UL,cULus,ATEX

Technical Principles and Innovative Values

Advanced Control Architecture:The ABB 3BHB021400R0002utilizes ABB’s proprietary Direct Torque Control(DTC)technology,providing superior motor performance with torque response times under 5 milliseconds.The module’s high-speed digital signal processor(DSP)executes complex control algorithms at 3kHz switching frequency,ensuring precise motor control without requiring encoder feedback in standard applications.The ABB 3BHB021400R0002achieves speed control accuracy of±0.1%and torque accuracy of±2%across the entire operating range,making it suitable for the most demanding industrial applications.

Intelligent Power Management:Featuring advanced power semiconductor technology with IGCT(Integrated Gate-Commutated Thyristor)devices,the ABB 3BHB021400R0002delivers efficiency exceeding 98.5%at full load.The module incorporates active front-end technology with unity power factor operation,eliminating harmonic distortion and reducing input current requirements.The sophisticated DC link management system maintains stable bus voltage even during power dips up to 50%of nominal voltage for 500 milliseconds,ensuring continuous operation through grid disturbances.

Comprehensive Protection System:The ABB 3BHB021400R0002incorporates multi-level protection including real-time thermal monitoring of power semiconductors,motor thermal protection based on accurate thermal models,and comprehensive short-circuit protection.The module’s predictive maintenance capabilities monitor key parameters such as capacitor aging,fan performance,and semiconductor health,providing early warnings of potential failures.The arc-flash detection system can interrupt fault currents within 2 milliseconds,enhancing personnel safety and equipment protection.

Application Cases and Industry Value

In a mining conveyor system application in Australia,the ABB 3BHB021400R0002drive controllers were deployed to manage a 12-kilometer overland conveyor system transporting iron ore.The previous drive system suffered from frequent trips due to voltage sags and load variations,causing production interruptions and mechanical stress on the conveyor structure.After implementing ABB 3BHB021400R0002units with their advanced ride-through capability and load-sharing algorithms,the system achieved 99.7%availability over two years of continuous operation.The controllers’torque limiting functionality prevented belt slippage during startup under loaded conditions,while the power regeneration capability during downhill operation resulted in 35%energy savings.The remote monitoring features enabled predictive maintenance,reducing unplanned downtime by 60%compared to the previous system.

Related Product Combination Solutions

ABB 3BHB021400R0003-Higher power rating version

ABB 3BHB021400R0001-Lower power rating version

ABB 3BHB013085R0001-Control interface module

ABB 3BHB003394R0001-Power supply unit

ABB 3BHB007209R0001-I/O extension module

ABB 3BHB005243R0001-Communication interface

ABB 3BHB004835R0001-Cooling system component

ABB 3BHB008153R0001-Braking unit

Installation and Maintenance

Installation Requirements:The ABB 3BHB021400R0002requires professional installation in a controlled environment with adequate ventilation and cooling.The unit must be mounted in a properly rated enclosure with IP54 protection for industrial environments.Ensure proper clearances are maintained according to ABB’s installation guidelines-minimum 100mm above and below the unit for airflow.All power connections must be torqued to specified values using calibrated tools,and control wiring must be properly shielded and routed separately from power cables.

Maintenance Protocol:Regular maintenance includes quarterly inspection of power connections for tightness,semi-annual cleaning of cooling surfaces,and annual calibration verification.Monitor the unit’s built-in diagnostic parameters including semiconductor temperatures,DC link capacitor health,and cooling system performance.Maintain logs of operational hours and performance metrics for predictive maintenance planning.Use ABB’s dedicated service tools for firmware updates and comprehensive system diagnostics.

Technical Support Commitment:We provide comprehensive support for the ABB 3BHB021400R0002,including system design assistance,installation supervision,and 24/7 technical support.Our field service engineers are trained in ABB’s high-power drive systems and can provide emergency response within 24 hours for critical applications.We maintain an inventory of critical spare parts to minimize downtime in case of component failure.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: