Description

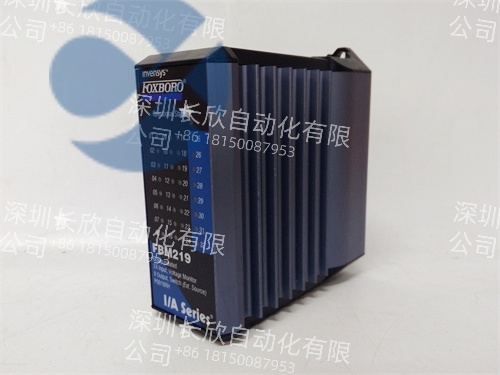

Product Overview

As part of FOXBORO’s comprehensive I/A Series DCS platform,theFBM219 P0916RHmodule provides robust signal processing capabilities in a compact form factor.The module supports voltage monitoring functions and offers group isolation for each input/output channel,ensuring reliable operation in harsh industrial environments.TheFOXBORO FBM219 P0916RHis engineered to handle discrete signals with voltages ranging from 15-60V DC,120V AC/125V DC,and 240V AC,providing flexibility for different industrial applications.

The strategic importance of theFOXBORO FBM219 P0916RHlies in its ability to bridge the gap between field devices and control systems,enabling seamless integration of sensors,switches,and actuators into the automation network.The module’s design emphasizes durability and reliability,with features such as configurable input filtering times,fault-safe configurations,and comprehensive diagnostic capabilities.TheFOXBORO FBM219 P0916RHis particularly valuable in applications where process safety and equipment protection are critical requirements.

Technical Specifications

Parameter Name

Parameter Value

Product Model

FBM219 P0916RH

Manufacturer

FOXBORO(Schneider Electric)

Product Type

Discrete I/O Interface Module

Input Channels

24 discrete inputs

Output Channels

8 discrete outputs

Input Voltage Range

15-60V DC,120V AC/125V DC,240V AC

Operating Temperature

-20°C to+60°C

Storage Temperature

-40°C to+85°C

Power Supply

24V DC±10%

Power Consumption

6W maximum at 24V DC

Input Current

2.2 mA typical at 30V DC

Isolation

Group isolation for each channel

Filter Time

Configurable(0,4,8,16,32 ms)

Dimensions

Standard FBM module size

Weight

2kg

Installation

DIN rail mounting

Protection Rating

IP20

Main Features and Advantages

High Channel Density and Flexibility:TheFOXBORO FBM219 P0916RHoffers an impressive channel configuration with 24 discrete inputs and 8 discrete outputs in a compact form factor.This high channel density allows for efficient use of control cabinet space while providing comprehensive I/O capabilities.The module supports multiple voltage ranges including 15-60V DC,120V AC/125V DC,and 240V AC,making it versatile for various industrial applications.TheFOXBORO FBM219 P0916RHfeatures configurable input filtering times that can be set to 0,4,8,16,or 32 milliseconds,allowing users to optimize signal processing for different noise environments and response time requirements.

Robust Isolation and Safety Features:Each input and output channel in theFOXBORO FBM219 P0916RHis group isolated,providing excellent noise immunity and protection against ground loops.This isolation ensures reliable operation in electrically noisy industrial environments and prevents signal degradation.The module includes comprehensive fault-safe configurations and diagnostic capabilities,enabling early detection of potential issues and preventing system failures.TheFOXBORO FBM219 P0916RHalso supports fault-safe fallback configurations,ensuring that outputs maintain safe states during communication failures or power interruptions.

Advanced Signal Processing and Integration:TheFOXBORO FBM219 P0916RHmodule features advanced signal processing capabilities with configurable filtering and debouncing functions.This allows for precise signal conditioning and reliable detection of digital states even in the presence of electrical noise.The module seamlessly integrates with FOXBORO’s I/A Series DCS platform,providing comprehensive data acquisition and control functions.TheFOXBORO FBM219 P0916RHsupports various terminal assemblies with different signal conditioning options,including current limiting devices,fuses,relays,and optical isolation,making it adaptable to specific application requirements.

Application Field

Oil and Gas Industry represents a primary application area for theFOXBORO FBM219 P0916RH,particularly in offshore platforms,refineries,and pipeline operations.In these critical environments,the module is used for emergency shutdown systems(ESD),fire and gas detection systems,and process monitoring applications.TheFOXBORO FBM219 P0916RH’s robust design and high reliability make it suitable for safety-critical applications where equipment protection and personnel safety are paramount.The module’s ability to handle multiple voltage ranges and its excellent noise immunity ensure reliable operation in the electrically challenging environments typical of oil and gas facilities.

Chemical and Petrochemical Plants extensively utilize theFOXBORO FBM219 P0916RHfor process control and safety applications.In chemical manufacturing processes,the module monitors critical parameters such as pressure switches,level sensors,and temperature alarms.TheFOXBORO FBM219 P0916RH’s configurable filtering capabilities allow it to handle noisy signals from pumps,motors,and other rotating equipment commonly found in chemical plants.The module’s group isolation feature prevents ground loops and ensures accurate signal measurement in corrosive and explosive environments typical of chemical processing facilities.

Power Generation and Water Treatment Facilities leverage theFOXBORO FBM219 P0916RHfor monitoring and control applications.In power plants,the module interfaces with turbine protection systems,generator monitoring equipment,and switchgear status indicators.TheFOXBORO FBM219 P0916RH’s wide operating temperature range and robust construction make it suitable for the harsh conditions found in power generation facilities.In water treatment plants,the module monitors pump status,valve positions,and level sensors,ensuring reliable operation of critical water infrastructure.The module’s diagnostic capabilities help maintenance personnel quickly identify and address issues,minimizing downtime and ensuring continuous operation.

Related Products

FOXBORO FBM212:8-channel fieldbus module supporting HART and Foundation Fieldbus protocols

FOXBORO FBM215:8-channel analog input/output module for process control applications

FOXBORO FBM218:16-channel discrete I/O module with relay or transistor outputs

FOXBORO FBM216B:16-channel module with HART communication support

FOXBORO FBM214:8-channel general-purpose I/O module with Foundation Fieldbus support

FOXBORO FCP280:Field control processor for distributed control applications

FOXBORO CP60 P0961FR:Advanced control processor for I/A Series systems

FOXBORO AW Series:Operator workstations for system monitoring and control

FOXBORO I/A Series:Complete distributed control system platform

FOXBORO FCM100E:Communication module for network connectivity

Installation and Maintenance

Pre-installation preparation:Proper installation of theFOXBORO FBM219 P0916RHrequires careful planning and adherence to industrial automation standards.Before installation,verify that the control cabinet provides adequate space for proper ventilation and maintenance access,with appropriate clearances around the module.Ensure the DIN rail is properly secured and that the mounting surface is clean and free from contaminants.Check that the power supply meets the module’s requirements(24V DC±10%)and verify proper grounding connections.All field wiring should use appropriate cable types and follow separation guidelines to prevent electrical interference.TheFOXBORO FBM219 P0916RHshould be handled with care to avoid damage to connectors and components,and static discharge precautions should be observed during installation.

Maintenance recommendations:Regular maintenance of theFOXBORO FBM219 P0916RHfocuses on ensuring optimal performance through systematic testing and inspection.Establish a preventive maintenance schedule that includes quarterly visual inspections for signs of damage,contamination,or loose connections.Perform regular function testing of I/O channels to verify proper operation and signal integrity.TheFOXBORO FBM219 P0916RH’s diagnostic capabilities should be monitored continuously for any fault indications.Keep detailed records of all maintenance activities,function tests,and any operational issues encountered.The modular design of theFOXBORO FBM219 P0916RHfacilitates easy replacement if necessary,minimizing system downtime during maintenance operations while maintaining process control.

Product Guarantee

We guarantee that theFOXBORO FBM219 P0916RHmeets all manufacturer specifications and performance requirements for industrial automation applications.Our comprehensive quality assurance process includes rigorous testing and validation procedures to ensure reliable operation in demanding industrial environments.We provide complete technical support covering system configuration,signal conditioning guidance,and operational troubleshooting to ensure successful implementation of theFOXBORO FBM219 P0916RHin your automation system.Our commitment extends throughout the product lifecycle,with ongoing support for performance optimization and maintenance planning.We maintain adequate inventory of critical components to support urgent requirements and offer replacement services for defective units within warranty terms,ensuring continuous operation of your industrial processes.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: