Description

Description

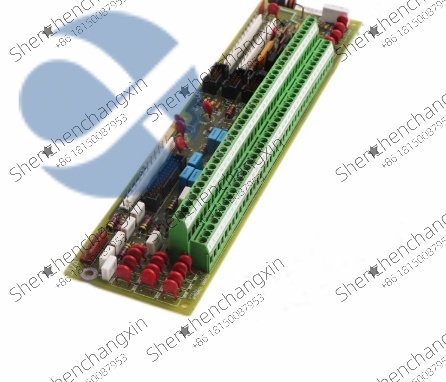

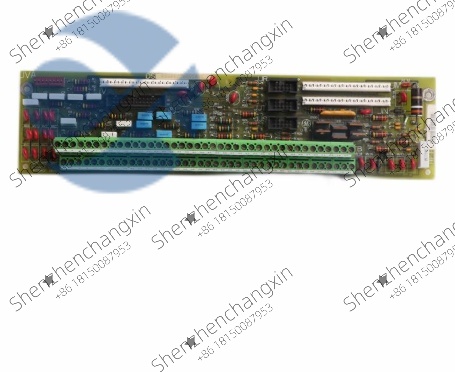

The GE DS200PTBAG1ADC is a high-reliability power module developed by General Electric specifically for industrial control systems.As the core power supply component for mainstream control systems such as the GE Mark VIe and Mark VI,it provides stable DC power to key components within the system,including control boards,signal modules,and communication units.Based on wide-voltage input and low-ripple output technology,this module boasts strong interference immunity,redundant compatibility,and a wide temperature range.It continuously outputs stable voltage under the harsh power grid environments and complex operating conditions found in industries such as power,petrochemicals,and metallurgy,effectively preventing system downtime or data loss caused by power supply fluctuations.It is the”energy heart”that ensures the continuous,safe,and efficient operation of industrial control systems.

Application Scenarios

A large gas turbine power plant’s two 390MW units used a GE Mark VIe control system.Previously,due to frequent grid voltage fluctuations(which ranged from a minimum of 340V AC to a maximum of 420V AC),the original power module frequently experienced unstable output voltage,leading to intermittent control system crashes and two to three unplanned outages per month,with each outage costing over 1.5 million yuan.Replacing the power module with a GE DS200PTBAG1ADC power module significantly improved the situation.The module’s wide 380-480V AC input voltage easily handles grid fluctuations;its low-ripple output(≤50mV)ensures stable control board operation;and its redundant power supply with another module of the same model ensures seamless failover.Following the upgrade,the unit’s control system experienced no outages due to power supply issues for 12 consecutive months,increasing equipment availability from 96.5%to 99.8%.The power plant’s electrical director stated,”The DS200PTBAG1ADC has completely resolved our power supply issues,reducing not only our economic losses but also the workload of our operations and maintenance team.”

Parameter

Core Parameters

Value/Description

Product Model

GE DS200PTBAG1ADC

Manufacturer

GE(General Electric Company)

Product Category

DC Power Supply Module for Industrial Control Systems

Input Voltage

380-480V AC(3-phase),wide voltage range to accommodate grid fluctuations

Output Voltage

24V DC(main output),5V DC(auxiliary output)

Output Current

24V DC:10A;5V DC:5A

Output Ripple

≤50mV(24V output),≤20mV(5V output)Output),ensuring precision circuit stability.

Efficiency:≥92%(full load),low energy consumption reduces operating costs.

Operating Temperature:-10°C to 60°C

Storage Temperature:-40°C to 85°C

Protection Rating:IP20(suitable for control cabinet installation,requires dust-proof and heat dissipation design).

Dimensions(L×W×H):220mm×180mm×100mm

Weight:3.5kg

Protection Features:Overvoltage protection(24V output:27-29V;5V output:5.5-5.8V),overcurrent protection,short-circuit protection,overtemperature protection.

Compatible Systems:GE Mark VIe,Mark VI,and Mark V control systems;compatible with third-party industrial control equipment(voltage and current requirements must match).

Redundancy Support:Supports N+1 redundant parallel operation for seamless failover.

Certifications:CE,UL 508,IEC 61010-1

Technical Principles and Innovative Values

Innovation 1:Wide-Voltage Input and Adaptive Regulation Technology–Utilizing a three-phase PFC(power factor correction)circuit and a wide voltage range adaptability design,the module operates stably with an input voltage between 380-480V AC,eliminating the need for manual adjustment.A built-in voltage compensation algorithm keeps output voltage fluctuations within±1%even when the grid voltage fluctuates by±15%,significantly exceeding the±5%accuracy of conventional power modules.In a steel plant application,the module can provide stable power to the control system even when the grid voltage drops due to large motor startups and shutdowns,preventing equipment downtime.

Innovation 2:Optimized Low-Ripple Output Design–Multi-stage LC filtering and synchronous rectification are used at the output to reduce output ripple to below 50mV,effectively suppressing interference from power supply noise on precision components such as control boards and sensors.In a chemical plant’s reactor control system,the module powers the PLC analog input module,reducing temperature measurement error from±0.5°C to±0.1°C and improving process control accuracy.Innovation 3:Redundancy and Fault Recovery–This module supports multi-module parallel redundancy(up to four modules).A built-in redundant control chip enables load balancing and fault detection.If a module fails,the remaining modules take over the load within 10ms,eliminating the need for manual restarts.Furthermore,the modules automatically recover from overtemperature and overcurrent conditions,eliminating the need for manual restarts.This significantly improves system reliability in remote,unmanned pumping station applications.

Innovation 4:Efficient Heat Dissipation and Long-Life Design–This module utilizes a copper-aluminum composite heat sink and an intelligent temperature-controlled fan.The fan speed automatically adjusts based on module temperature,ensuring efficient heat dissipation and reducing fan wear.Key components(such as capacitors and IGBTs)are industrial-grade,long-life models with a design life of 100,000 hours,1.5 times that of conventional power modules,reducing spare part replacement frequency and maintenance costs.Application Cases and Industry Value

Case 1:Control and Power Supply for a Petrochemical Catalytic Cracking Unit

A refinery’s 3.5 million tons/year catalytic cracking unit used a GE Mark VI control system.The original power module’s low efficiency(85%)and high ripple(150mV)led to frequent data transmission errors on the control board,necessitating two monthly shutdowns for calibration,each impacting production by approximately 500 tons.After replacing it with the DS200PTBAG1ADC,the module’s high efficiency of 92%reduced the temperature rise in the control cabinet from 45°C to 38°C,while its low-ripple output eliminated data transmission errors.Furthermore,its redundant configuration prevented downtime due to power failures.Following the retrofit,the unit experienced no downtime due to power supply issues for 18 consecutive months,resulting in an increase in annual production of approximately 12,000 tons.Based on a profit of 300 yuan per ton of crude oil processed,this translates to an additional annual revenue of 3.6 million yuan.Case 2:Power Supply Upgrade for a Rolling Mill Control System in the Metallurgical Industry

A steel plant’s hot-rolling production line’s main mill control system uses a GE Mark V system.The original power module was unable to withstand the high temperatures in the workshop(the temperature inside the control cabinet reaches 55°C in summer)and power grid fluctuations.Power failures caused approximately five mill shutdowns annually,with each shutdown costing over 800,000 yuan.After installing the DS200PTBAG1ADC,the module’s wide operating temperature and high-temperature protection ensured stable output even at 55°C.Its wide input voltage addressable power grid fluctuations,combined with its redundant configuration,completely resolved the power supply issue.After the upgrade,the mill’s annual shutdown rate has been reduced to zero,saving 4 million yuan in losses.Furthermore,the module’s long lifespan means it will not need replacement for five years,reducing spare parts costs by approximately 200,000 yuan.

Related Product Combination Solutions

GE Mark VIe Control System–Deeply compatible with the DS200PTBAG1ADC,the module provides stable power for the system’s CPU board,I/O modules,and communication modules,forming a complete control solution.

GE DS200PLCAG101A Logic Control Board–Powered by the DS200PTBAG1ADC with 24V DC,it implements logic control and signal processing for industrial equipment,improving control accuracy and reliability.

GE IS200TBSCH1A Terminal Block–Provides mounting and wiring interfaces for the DS200PTBAG1ADC,facilitating module mounting and wiring within the control cabinet and improving installation efficiency.

Phoenix Contact QUINT-DIODE/40 Redundant Diode Module–Combined with the DS200PTBAG1ADC,it enables redundant parallel operation of two modules,ensuring seamless load transfer in the event of a fault.Suitable for critical control scenarios.

ABB ACS880 inverter–When the DS200PTBAG1ADC powers the inverter’s control unit,it improves operational stability and prevents failures caused by power supply fluctuations.

GE Proficy HMI/SCADA iFIX–The DS200PTBAG1ADC provides stable power to the industrial computer running the human-machine interface(HMI)software,ensuring continuous operation of the HMI system and real-time display and control of industrial equipment status.

Siemens S7-1500 PLC–If interoperability with GE control systems is required,the DS200PTBAG1ADC can provide an adaptive power supply to the PLC via a voltage conversion module,enabling cross-brand device interoperability.

GE DS200PCCAG101 power supply monitoring board–Real-time monitoring of the DS200PTBAG1ADC’s output voltage,current,temperature,and other parameters.When an abnormality occurs,an alarm is issued,facilitating timely action by maintenance personnel.

Installation,Maintenance,and Full-Cycle Support

Installation Specifications

Cabinet Installation:Install the DS200PTBAG1ADC on a 35mm DIN rail in the control cabinet.Ensure≥50mm of heat dissipation clearance around the module to avoid direct contact with high-power heat-generating components(such as inverters and contactors).If a redundant configuration is used,the two modules must be≥30mm apart to facilitate heat dissipation and wiring.

Wiring Requirements:The input side must be connected to a 3-phase 380-480V AC power supply with a 16A circuit breaker and surge protector.The output side must connect the 24V DC and 5V DC power supplies to the corresponding loads.Ensure proper polarity when wiring to avoid reverse polarity.In a redundant configuration,redundant diode modules must be used to connect the output terminals to ensure load balancing.

Commissioning Verification:Before powering on,check the wiring for correctness and ensure there are no short circuits or reverse connections.After powering on,verify the module’s operating status using the module’s built-in LED indicators(power,fault,and redundancy status).Use a multimeter to measure the output voltage to ensure the 24V DC output is within the 23.5-24.5V range and the 5V DC output is within the 4.9-5.1V range.

Maintenance Key Points

Daily Inspection:Check the module’s LED indicators weekly(normal operation is indicated by a solid green power light and no fault lights).Use an infrared thermometer to measure the module’s surface temperature to ensure it does not exceed 60°C.Check the input and output terminals for looseness and signs of heat and oxidation.

Regular Maintenance:Clean dust from the module’s surface and cooling fan every three months to ensure proper heat dissipation.Measure the output voltage and ripple every six months to verify module performance.Perform a fault simulation test on the redundant system annually to confirm the redundancy switchover function is functioning properly.Troubleshooting:If the module fault light illuminates,first check whether the input voltage is normal and whether the load is overloaded.If the output voltage is abnormal,check the internal filter capacitor and rectifier circuit.When replacing a module,first disconnect the input power.In a redundant configuration,switch to the backup module before replacing the faulty module to ensure uninterrupted system operation.

Full-Life Support

Warranty Service:A 24-month factory warranty is provided.During the warranty period,if a module fails due to quality issues(such as component failure or abnormal output),it will be replaced free of charge.Technical support is also provided to assist with installation and commissioning.

Technical Support:A professional 24/7 technical support team is available to assist users with installation,commissioning,and troubleshooting issues via phone,email,and remote guidance,with a response time of≤2 hours.On-site technical services are also available,providing customized guidance for complex system power supply solutions.

Spare Parts Supply:Spare parts warehouses are located in multiple regions nationwide to ensure rapid supply of the DS200PTBAG1ADC module and related accessories(such as redundant diodes and terminal blocks),minimizing equipment downtime.

Training Services:We provide users with module operation,maintenance,and troubleshooting training,covering operating principles,installation specifications,redundant configuration,and troubleshooting.This helps users master module usage skills and improve operational efficiency.

The GE DS200PTBAG1ADC power module,with its high stability,wide adaptability,and strong reliability,is an ideal component for industrial control system power supply.Whether you need to upgrade the power supply unit of an existing control system or build a reliable power supply solution for new equipment,it provides solid energy support for safe operation.If you have power supply requirements for specific industries(such as nuclear power,aerospace)or special operating conditions(such as extreme cold or high dust),please provide detailed information.We can further customize a customized power supply solution and provide technical support.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: