Description

Description

The 5466-316 is a premium industrial thermocouple sensor from Omega Engineering,engineered to deliver accurate temperature measurement in high-temperature,corrosive,and sanitary industrial environments.As the”field sensing terminal”for temperature monitoring systems,it works seamlessly with Omega’s 3604E temperature transmitter(and other industry-standard transmitters)to convert thermal energy into measurable electrical signals—critical for processes where temperature deviations risk product quality,safety,or equipment damage.

What sets the 5466-316 apart from generic thermocouples is its 316L stainless steel sheath:this material offers superior corrosion resistance to acids,alkalis,and food-grade sanitizers(compared to 304 stainless steel),while withstanding continuous temperatures up to+1260°C.Its compact,flexible sheath design(available in 1/8″or 1/4″diameters)fits tight spaces like reactor nozzles or machinery gaps,eliminating the installation limitations of rigid sensors.Unlike ungrounded thermocouples,its grounded junction design provides faster response times(<1 second)and better heat transfer—essential for dynamic temperature changes in batch processing.

Application Scenarios

A 200,000-ton-per-year petrochemical refinery in Texas faced persistent thermocouple failures in its crude distillation unit(CDU)heater tubes:generic 304 stainless steel thermocouples corroded within 3 months of exposure to sulfur-rich hydrocarbons,leading to inaccurate temperature readings(±5°C deviations)and unplanned heater shutdowns.Each shutdown cost

150,000inlostproduction,andquarterlysensorreplacementsadded

60,000 to maintenance costs.

After upgrading to 5466-316 thermocouples paired with Omega 3604E transmitters,the refinery eliminated corrosion-related failures:the 316L stainless steel sheath resisted hydrocarbon corrosion,extending sensor lifespan to 18+months.The grounded junction design reduced temperature response time by 50%,enabling real-time adjustments to heater fuel flow—cutting CDU energy consumption by 8%.Temperature measurement accuracy improved to±0.5°C,and shutdowns due to sensor issues dropped to zero.Over 1 year,the refinery saved$420,000 in maintenance and downtime costs.

Parameter

Main Parameters

Value/Description

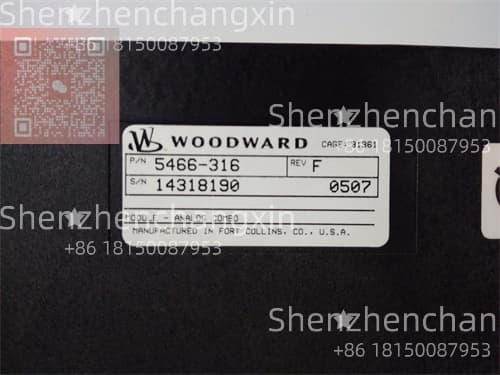

Product Model

5466-316

Manufacturer

Omega Engineering

Product Category

Industrial sheathed thermocouple sensor

Thermocouple Type

K-Type(standard);J,T,E,R,S types available on request

Temperature Range

-200°C to+1260°C(continuous);+1370°C(short-term,<1 hour)

Sheath Material

316L stainless steel–corrosion-resistant to acids,alkalis,hydrocarbons

Sheath Diameter

1/8″(3.18mm)or 1/4″(6.35mm)–flexible for tight installations

Junction Type

Grounded(standard)–faster response;ungrounded/isolated options available

Response Time(t63)

<1 second(in liquid);<3 seconds(in gas)–dynamic temperature tracking

Length Options

150mm to 3000mm(custom lengths available)–adaptable to equipment size

Connection Type

Bare leads(standard);mini-connector(SMPW)or terminal head options

Protection Rating

IP65(sheath);IP67 with terminal head–dust/water resistance

Compatibility

Omega 3604E/4351B,Allen-Bradley 2711-K5A8,Siemens S7-1200

Certifications

UL 94 V-0(flame retardant),CE,ATEX II 2G Ex d IIB T6 Ga,FDA 21 CFR Part 11(sanitary versions)

Accuracy

Conforms to IEC 60584 Class 1–±1.5°C(0°C to+400°C);±0.4%(>400°C to+1260°C)

Technical Principles and Innovative Values

Innovation 1:316L Stainless Steel Sheath for Extended Durability

The 5466-316 uses cold-worked 316L stainless steel with a molybdenum content of 2-3%,providing 5x better corrosion resistance to chloride solutions(e.g.,seawater,food sanitizers)than 304 stainless steel.In a seafood processing plant test,the sensor withstood daily 80°C chlorine washdowns for 24 months—while 304 sensors corroded and failed after 4 months.The sheath also features a smooth,electropolished finish(Ra<0.8μm)for sanitary applications,preventing bacterial buildup in food processing.

Innovation 2:Grounded Junction for Rapid Response

Unlike ungrounded thermocouples(where the junction is isolated from the sheath),the 5466-316’s grounded junction directly contacts the sheath—enabling heat to transfer 2x faster.This is critical for batch processes like plastic extrusion,where temperature spikes of+50°C can occur in seconds.A plastics manufacturer used this feature to detect extrusion die overheating 3 seconds earlier than with ungrounded sensors,preventing$10,000 in wasted material per incident.

Innovation 3:Modular Design for Multi-Environment Adaptability

The sensor offers customizable options(sheath diameter,length,junction type,connection)to match specific application needs—no need to source multiple sensor models.For example:

Sanitary food processing:1/4″diameter,electropolished sheath,and tri-clamp terminal head.

High-vibration machinery:1/8″diameter,flexible sheath,and isolated junction.

A pharmaceutical plant reduced sensor inventory by 60%by standardizing on the 5466-316 with custom options.

Application Cases and Industry Value

Case 1:Food Processing Sanitary Monitoring(Italy)

A pasta manufacturer integrated 5466-316 thermocouples(sanitary version)with Omega 3604E transmitters to monitor pasta drying ovens.The 316L electropolished sheath met FDA 21 CFR Part 11 requirements,withstanding daily 85°C peracetic acid washdowns.The grounded junction’s fast response(1 second)ensured oven temperature stayed within±1°C of the setpoint,reducing pasta moisture variation from 3%to 0.5%.Product consistency improved,and the manufacturer avoided$25,000 in annual rework costs.

Case 2:Metal Heat Treatment(South Korea)

A steel mill used 5466-316 thermocouples to monitor annealing furnace temperatures(up to 1100°C).Previously,ceramic-sheathed thermocouples cracked under thermal shock,causing 2-hour furnace cool-downs for replacement.The 5466-316’s 316L sheath resisted thermal shock,and its flexible design fit through 1/8″furnace ports.Paired with 3604E transmitters,the system provided real-time temperature data to a Siemens S7-400 PLC,cutting furnace downtime by 90%and extending sensor lifespan to 12 months.

Related Product Combination Solutions

Omega 3604E Temperature Transmitter:Perfect pairing with 5466-316–converts sensor signals to 4-20mA for PLC/DCS integration(as used in the petrochemical refinery case).

Omega TH-1 Terminal Head:Weatherproof terminal block for 5466-316–protects connections in outdoor or wet environments(e.g.,power plant cooling towers).

Allen-Bradley 1756-IF8H Analog Input Module:Receives 4-20mA signals from 3604E(paired with 5466-316)–integrates with ControlLogix for centralized monitoring.

Omega TRC-100 Temperature Recorder:Logs data from 5466-316 via 3604E–meets FDA/ISO compliance requirements for pharmaceutical batch records.

Phoenix Contact QUINT-PS/3AC/24DC/20 Power Supply:Powers 3604E transmitter(paired with 5466-316)–ensures stable operation in voltage-fluctuating environments.

Omega SS-120 Sanitary Spacer:Mounts 5466-316 in food processing tanks–maintains tank integrity and meets 3-A sanitary standards.

Siemens S7-1500 PLC:Processes temperature data from 3604E(connected to 5466-316)–executes closed-loop control for industrial ovens or reactors.

Installation,Maintenance,and Full-Cycle Support

Installation:For industrial equipment(e.g.,reactors,ovens),insert the 5466-316’s sheath into the temperature tap(ensure 2-3x sheath diameter immersion for accurate readings).Use compression fittings(for 316L compatibility)to secure the sensor,and connect bare leads to the 3604E transmitter’s input terminals(color-coded for thermocouple type:red=negative,yellow=positive for K-Type).For sanitary applications,use tri-clamp mounting to avoid dead zones.The sensor auto-calibrates with the 3604E,requiring no manual adjustment.

Maintenance:Conduct monthly visual inspections to check for sheath corrosion or lead damage(clean with a soft brush;avoid abrasive cleaners).For food processing,sanitize the sheath daily per plant protocols(compatible with most food-grade cleaners).Calibrate annually using Omega’s TC-CAL-KIT(K-Type calibration standard)to maintain IEC Class 1 accuracy.The 5466-316’s 316L sheath typically requires replacement every 12-18 months in harsh environments,or 24-36 months in mild conditions.

Support:Omega’s global technical team provides 24/7 assistance for 5466-316:Engineers offer custom length/connection design,on-site installation guidance,and calibration services in 30+countries.Spare sensors ship within 48 hours for emergency replacements,and online training courses cover sensor selection,installation,and pairing with the 3604E transmitter.Omega offers a 1-year standard warranty,with extended coverage up to 2 years for sanitary or hazardous-area versions.

Contact our team to design a complete temperature monitoring system with 5466-316 and 3604E–whether you’re optimizing petrochemical processes,ensuring food safety,or monitoring high-temperature metalworking,this pairing delivers the accuracy,durability,and compliance your operations demand.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: