Description

Application Scenarios

At a Tier-1 automotive supplier in Michigan,an IRB 4400 robot arm suddenly stopped responding during a critical welding cycle.Diagnostics pointed to a failed motion controller,halting the entire production line.After sourcing a tested ABB 3BSE005178R1(DSQC100.1)replacement,the team reinstalled it within 30 minutes—no firmware reprogramming required.The robot resumed operation with full precision,avoiding over$50,000 in potential downtime losses.This case underscores how the ABB 3BSE005178R1 isn’t just a spare part—it’s a production lifeline in high-uptime manufacturing environments.

Parameter

Main Parameters Value/Description

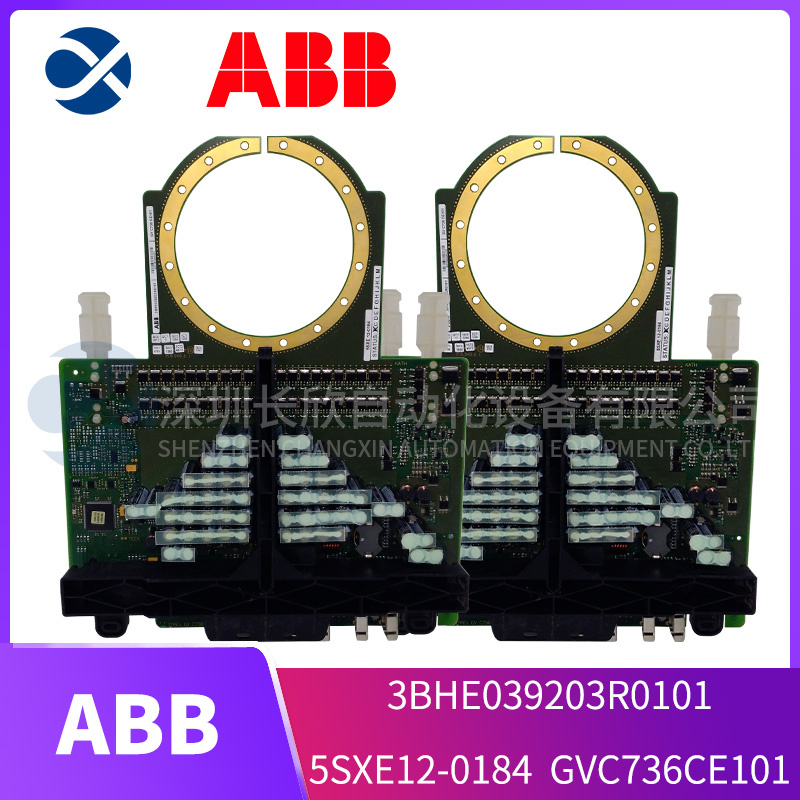

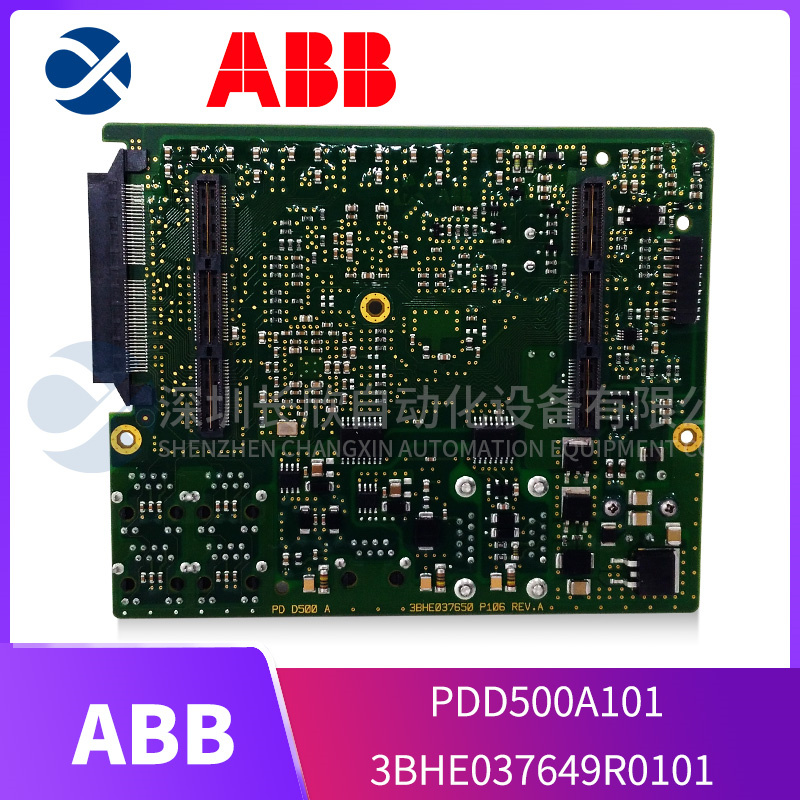

Product Model 3BSE005178R1

Manufacturer ABB Robotics

Product Category Robot Motion Controller/Axis Computer Module

Common Name DSQC100.1

Compatible Robots ABB IRB 2400,IRB 4400,IRB 6400(Series A/B)

Function Axis motion control,servo signal processing,position feedback handling

Communication Interface ABB proprietary bus(connects to Main Computer Module M2002/M2004)

Installation Method Rack-mounted in robot controller cabinet(fixed via screws)

Power Supply Powered via backplane from robot controller PSU(typically 24 V DC)

Environmental Class Industrial grade:-10°C to+55°C,5–95%RH non-condensing

Protection Level IP20(intended for installation in enclosed control cabinets)

Diagnostic Features LED status indicators(RUN,ERROR,COMM)for quick fault identification

Upgrade Path Can be replaced with refurbished or remanufactured 3BSE005178R1 units seamlessly

Safety Function Support Participates in robot safety chain(enables brake release,monitors motor feedback)

Technical Principles and Innovative Values

Innovation Point 1:Real-Time Motion Intelligence

The ABB 3BSE005178R1(DSQC100.1)is not a passive I/O module—it’s an embedded motion computer.It processes encoder feedback,calculates torque commands,and synchronizes up to six axes in real time,ensuring smooth kinematic motion.This level of deterministic control is critical for path accuracy in arc welding and dispensing applications.

Innovation Point 2:Seamless Integration with ABB RobotWare

Unlike third-party replacements,the original ABB 3BSE005178R1 is fully certified to work with ABB’s RobotWare operating system.It supports automatic calibration loading and zero-point memory recall,eliminating manual teach-in after replacement—saving hours of downtime.

Innovation Point 3:Hardware-Level Safety Interlocks

The module integrates directly with ABB’s safety architecture.It validates motor feedback before enabling brake release and monitors position deviation in real time.If an axis drifts beyond tolerance,the ABB 3BSE005178R1 triggers a safety stop—protecting both equipment and personnel.

Innovation Point 4:Plug-and-Play Replacement Design

ABB engineered the 3BSE005178R1 for rapid field replacement.No firmware flashing or configuration is needed.Once installed,the main controller automatically detects the module and resumes operation using stored calibration data—ideal for emergency repairs.

Application Cases and Industry Value

A beverage bottling plant in Brazil relied on an IRB 2400 for palletizing operations.When the ABB 3BSE005178R1 failed,production halted.A remanufactured unit was shipped overnight and installed the next morning.The robot resumed full operation without recalibration,restoring throughput within hours.The plant manager noted that using a non-ABB alternative would have required a full system revalidation—costing days and risking compliance issues.

In another case,a German automation integrator upgraded a legacy IRB 4400 cell.Instead of scrapping the controller,they replaced aging ABB 3BSE005178R1 modules with tested originals.This extended the robot’s service life by five years,delivering a 60%cost saving versus a new system.The ABB 3BSE005178R1 proved that legacy components,when properly maintained,can deliver modern reliability.

Related Product Combination Solutions

M2002/M2004:Main computer modules that communicate with the ABB 3BSE005178R1 to coordinate robot motion and logic.

DSQC200/DSQC210:I/O and safety modules that work alongside the ABB 3BSE005178R1 in the same control cabinet.

3HAC027787-001:Motor cable assembly connecting the ABB 3BSE005178R1 to robot joint motors.

3HAC032408-001:Encoder cable for feedback loop integrity between axes and the ABB 3BSE005178R1.

3BSE005179R1:Power supply unit(PSU)for the robot controller,providing stable 24V to the ABB 3BSE005178R1.

3HAC021887-001:Teaching pendant(FlexPendant)used to monitor and debug the ABB 3BSE005178R1 status.

3BSE005180R1:Memory backup unit(battery module)preserving calibration data when the ABB 3BSE005178R1 is replaced.

IRB 4400:One of the most common robot models utilizing the ABB 3BSE005178R1,widely used in welding and material handling.

Installation,Maintenance,and Full-Cycle Support

Replacing the ABB 3BSE005178R1 requires powering down the robot controller,removing the front panel,and unscrewing the faulty module.The new unit slides into the same slot and is secured with screws—no wiring changes needed.Upon power-up,the system automatically recognizes the module.It’s critical to ensure the robot’s mechanical units are at their home position and that the backup battery is functional to retain calibration data.

Routine maintenance includes visual inspection of connectors and cleaning dust from the controller cabinet.The ABB 3BSE005178R1 has no user-serviceable parts,but its solid-state design ensures long service life.When failure occurs,quick replacement is the standard practice.

We provide fully tested ABB 3BSE005178R1 modules,each verified for communication,signal integrity,and compatibility.Every unit comes with an 18-month warranty and access to technical support for installation guidance.Our global inventory ensures fast delivery for emergency repairs.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: