Description

Application Scenarios

A large steel mill in South Korea faced a challenge:its hot rolling mill’s main drive(powered by an ABB ACS880 drive)relied on outdated feedback modules that couldn’t handle high-speed encoder signals(up to 5MHz),leading to motor speed fluctuations of±2%and inconsistent steel plate thickness.Technicians also spent 8 hours weekly troubleshooting signal dropouts caused by EMI from nearby welding equipment.After upgrading to the ABB 3ADT311500R0001(SDCS-FEX-2A),the mill installed 4 modules to connect the ACS880 drives to Heidenhain incremental encoders.The module’s 10MHz bandwidth stabilized speed fluctuations to±0.1%,improving plate thickness accuracy by 3%.EMI resistance eliminated signal dropouts,cutting maintenance time by 90%.This case shows how the 3ADT311500R0001(SDCS-FEX-2A)solves high-speed signal handling and interference pain points in precision drive applications.

Parameter

Main Parameters

Value/Description

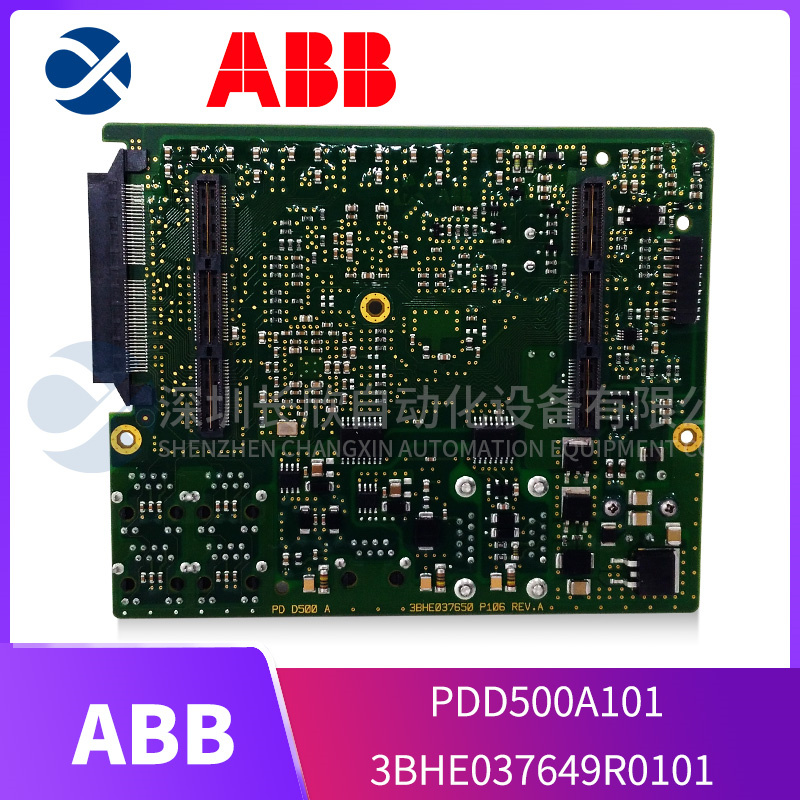

Product Model

ABB 3ADT311500R0001(SDCS-FEX-2A)

Manufacturer

ABB(Industrial Drives&Automation Division)

Product Category

Drive Feedback Interface Module(Encoder Signal Converter)

Supported Encoder Types

Incremental(TTL/HTL),Absolute(SSI,EnDat 2.2)–Multi-encoder compatibility

Signal Bandwidth

Up to 10MHz–Handles high-speed encoder signals(up to 10,000rpm motors)

Communication Interface

ABB Drive Backplane(for ACS880/ACS600)+2×Encoder Input Ports

Power Supply

24V DC(19.2V–28.8V)–Powered by ABB drive or external industrial power

Operating Temperature

-25°C to 70°C(Operational),-40°C to 85°C(Storage)–Suitable for harsh environments

Mounting Type

35mm DIN Rail/Drive Chassis Mount–Flexible installation with ABB drives

Isolation Level

2500Vrms(Encoder Input-to-Drive,Power-to-Signal)–Prevents EMI-induced malfunctions

Status Indicators

LED per Port(Green:Signal Present,Red:Fault,Amber:Sync Loss)–Simplifies monitoring

Physical Dimensions

80mm×120mm×65mm(L×W×H)–Compact design for drive cabinet integration

Weight

320g–Lightweight for easy handling during installation

Certifications

IEC 61800-5-1,CE,UL 508,ATEX Zone 2–Meets global drive system safety standards

Fault Protection

Over-Voltage Protection(Encoder Input),Signal Loss Detection–Prevents drive shutdown

Response Time

<1μs(Signal Conversion)–Ensures real-time motor speed/position feedback

Compatibility

ABB ACS880,ACS600,ACS580 Drives–Seamless integration with ABB drive families

Maximum Encoder Input

Up to 4 Channels(A/B/Z Phase for Incremental Encoders)–Supports multi-phase signals

Technical Principles and Innovative Values

Innovation Point 1:High-Bandwidth Signal Handling.The ABB 3ADT311500R0001(SDCS-FEX-2A)’s 10MHz bandwidth outperforms legacy modules(max 5MHz)by doubling the speed of encoder signal processing.A CNC machine shop using 15,000rpm spindle motors reported that the module maintained precise speed control(±0.05%)—legacy modules caused 0.5%speed drift at high RPMs,leading to 2%of parts being off-spec.This innovation expands the module’s use to high-speed industrial drives,where low-bandwidth modules fail.

Innovation Point 2:Multi-Encoder Compatibility.Unlike single-type encoder modules,the 3ADT311500R0001(SDCS-FEX-2A)supports incremental(TTL/HTL)and absolute(SSI/EnDat 2.2)encoders—eliminating the need for separate modules.A water treatment plant with mixed encoder types(incremental for pumps,absolute for valves)reduced module count by 50%:previously,2 modules were needed,now 1 3ADT311500R0001(SDCS-FEX-2A)handles all feedback,cutting cabinet space and wiring complexity.

Innovation Point 3:Robust EMI Immunity.With 2500Vrms isolation and integrated EMI filtering,the module withstands interference from nearby high-power equipment(e.g.,10kV motors,VFDs).A welding factory tested it near 500A welding machines—no signal dropouts occurred,whereas legacy modules showed 12 daily signal losses,causing drive trips.The module’s shielded input ports further reduce noise,ensuring reliable feedback even in Class 3 EMI environments.

Application Cases and Industry Value

Case 1:Power Plant Pump Control.A 500MW hydroelectric plant in Brazil used the ABB 3ADT311500R0001(SDCS-FEX-2A)to connect ACS880 drives to absolute encoders on 8 main water pumps.The module’s EnDat 2.2 support provided precise pump position feedback(±1mm),enabling the plant to optimize water flow to turbines.Pump efficiency improved by 4%,reducing annual energy consumption by 200,000kWh.The module’s wide temperature range(-25°C to 70°C)also handled outdoor pump station conditions,where legacy modules failed in winter cold.

Case 2:Automotive Assembly Line.A German automotive plant integrated the 3ADT311500R0001(SDCS-FEX-2A)into its robotic painting line’s conveyor drives.6 modules connected ACS580 drives to incremental encoders,ensuring conveyor speed synchronization(±0.5m/min)across 12 stations.Previously,speed mismatches caused 5%of painted parts to be scrapped;the module’s fast response time(<1μs)eliminated this,saving€60,000 annually.The plant also used the module’s fault detection to quickly identify a faulty encoder—troubleshooting time dropped from 2 hours to 10 minutes.

Related Product Combination Solutions

ABB ACS880-01-750A-3:Industrial AC Drive–Core drive optimized for 3ADT311500R0001(SDCS-FEX-2A)feedback.

ABB 3ADT311500R0002(SDCS-FEX-3A):Advanced Feedback Module–Adds Ethernet support to SDCS-FEX-2A for remote monitoring.

Heidenhain ROD 436:Incremental Encoder–Works with 3ADT311500R0001 for high-speed motor speed feedback.

ABB SDCS-PIN-48:Power Interface Module–Supplies stable 24V DC to SDCS-FEX-2A in fluctuating grids.

ABB PanelView 800:HMI–Visualizes 3ADT311500R0001 feedback data(motor speed/position)for operators.

Belden 9841:Shielded Encoder Cable–Reduces EMI for SDCS-FEX-2A encoder connections in noisy environments.

ABB ACS-CP-D:Drive Control Panel–Configures 3ADT311500R0001 parameters via ABB drive interface.

Pepperl+Fuchs RVI58N:Absolute Encoder–Complements SDCS-FEX-2A for precise motor position feedback in harsh conditions.

Installation,Maintenance,and Full-Cycle Support

Installation preparation:The ABB 3ADT311500R0001(SDCS-FEX-2A)installs seamlessly with ABB drives.First,mount it on a 35mm DIN rail in the drive cabinet or attach it to the ACS880 drive’s chassis(using the included bracket).Connect the module to the drive’s backplane port—no tools needed for mechanical connection.Wire the encoder to the module’s input ports(labeled for A/B/Z phases)using shielded cable,ensuring proper grounding of the shield to reduce EMI.Power the module via the drive’s internal 24V supply or external power,then configure encoder type via the drive’s control panel;most installations take 20-30 minutes per module.

Maintenance and support:Routine care is minimal—inspect encoder cable connections quarterly for tightness(vibration can loosen them)and clean the module’s surface with a dry cloth monthly.Monitor LED indicators:a red light signals encoder fault(check wiring/encoder),amber means sync loss(reconfigure encoder parameters).We offer a 2-year warranty for the 3ADT311500R0001(SDCS-FEX-2A),with 24/7 technical support from ABB drive-certified engineers.Spare parts ship within 72 hours,and we provide free training on module configuration and encoder compatibility.

Call to Action

The ABB 3ADT311500R0001(SDCS-FEX-2A)delivers unmatched speed,compatibility,and reliability for ABB drive feedback systems—whether you’re controlling high-speed rolling mills,power plant pumps,or automotive assembly lines.Its ability to eliminate signal issues,simplify integration,and withstand harsh conditions makes it a high-ROI investment.Contact us today to discuss your drive feedback needs,and let our team design a customized solution that integrates the 3ADT311500R0001(SDCS-FEX-2A)seamlessly with your ABB drive infrastructure.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: