Description

Application Scenarios

On a large offshore supply vessel operating in the North Sea,the DEIF GPU 2 GS units are installed in the main switchboards to protect four 2.5 MW diesel generators running in parallel.During a sudden short circuit on the main busbar,the GPU 2 GS detected the fault current within 15ms,executed differential protection logic,and sent a trip signal to the circuit breaker—successfully isolating the faulty section while keeping the other generators online.Its integrated synchronization supervision also prevents out-of-phase closing,protecting the prime movers from mechanical stress.The crew relies on its clear LED indicators and event log for rapid fault diagnosis during critical operations.

In a hospital backup power plant in Germany,two DEIF GPU 2 GS relays monitor a pair of 1.8 MW standby generators.When the utility grid failed during a storm,the generators started automatically.The GPU 2 GS verified correct voltage and frequency before closing the breaker to the emergency bus.Later,an internal winding fault in one generator was detected by the earth fault and differential protection functions,triggering an immediate shutdown and alarm.This prevented catastrophic generator damage and ensured the second unit remained operational,maintaining life-support systems—a testament to its role in mission-critical safety.

Parameter

Main Parameters Value/Description

Product Model DEIF GPU 2 GS

Manufacturer DEIF A/S(Denmark)

Product Category Generator Protection Relay/Unit

Protection Functions Differential,Overcurrent(I>,I>>),Earth Fault(Io>),Reverse Power,Over/Under Voltage,Over/Under Frequency,Thermal Overload

Trip Time<20 ms(typical for instantaneous functions)

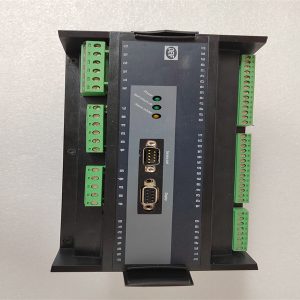

Inputs 3x CT(Current Transformer)inputs,3x VT(Voltage Transformer)inputs,Neutral CT input

Communication Interfaces RS-485(Modbus RTU),CANopen(for integration with DEIF PPU/AGC systems)

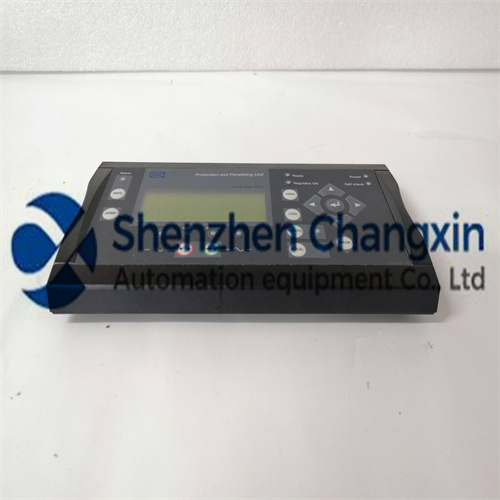

Display Integrated status LEDs;configurable via software or external HMI

Configuration Software DEIF Power Setup(Windows-based)

Safety Certification SIL 2 according to IEC 61508 and IEC 62345

Mounting DIN-rail(35 mm)

Power Supply 24–230 VAC/VDC(wide-range input)

Operating Temperature-25°C to+70°C

Environmental Rating IP20(front),suitable for industrial enclosures

Status Indicators RUN,TRIP,ALARM,and function-specific LEDs

Certifications DNV-GL,ABS,LR,BV,CCS,CE,RoHS

Technical Principles and Innovative Values

Innovation Point 1:Integrated differential protection allows the GPU 2 GS to detect internal generator faults(e.g.,stator winding shorts)with high sensitivity and speed,minimizing equipment damage.

Innovation Point 2:Dual communication protocols(Modbus&CANopen)enable seamless integration into both standard SCADA systems and DEIF’s proprietary Power Management Systems(PMS),offering flexibility in system design.

Innovation Point 3:SIL 2 certification ensures compliance with functional safety standards for emergency and backup power systems,providing a high level of confidence in its fail-safe operation.

Innovation Point 4:Wide power supply range(24–230 VAC/VDC)simplifies installation across global projects and different control voltage standards(e.g.,24VDC in marine,110VAC in industrial).

Innovation Point 5:Event recording and self-diagnostics continuously monitor relay health and log fault events with timestamps,aiding in post-event analysis and predictive maintenance.

Application Cases and Industry Value

A container ship retrofitted with DEIF GPU 2 GS units reported a 40%reduction in generator downtime after a phase-to-ground fault was correctly isolated without affecting the entire power system.The neutral earth fault protection pinpointed the issue,allowing targeted repairs.The CANopen interface synchronized data with the DEIF PPU 3 controller,enabling centralized monitoring from the bridge.

In a data center in Singapore,the GPU 2 GS protects 12 backup generators forming a N+1 redundancy array.Its reverse power protection prevents motors from acting as generators during grid faults,while thermal overload modeling protects against prolonged overloads.The event logs were instrumental during an audit by the local energy authority,proving system integrity and compliance with uptime requirements.

Related Product Combination Solutions

DEIF PPU 3:Power Management Controller–Central brain for generator sequencing and load sharing.

DEIF AGC 3:Automatic Grid Controller–For mains parallel and island grid operation.

DEIF GPP 3:Generator Protection Panel–Pre-assembled panels incorporating GPU 2 GS.

DEIF CM-W3:Multifunction Meter–For display and monitoring alongside protection.

DEIF Power Setup:Configuration&Diagnostics Software–Essential for setting up GPU 2 GS.

DEIF CAN HUB:Network Hub–Connects multiple DEIF devices via CANopen.

DEIF VT&CT Sensors:Compatible voltage and current transformers–Required field inputs.

DEIF TPW 3:Touch Panel HMI–For local operator interface and alarm acknowledgment.

Installation,Maintenance,and Full-Cycle Support

The DEIF GPU 2 GS installs on standard 35 mm DIN rail.Field connections include CTs,VTs,DC control power,and communication cables(RS-485/CAN).Use DEIF Power Setup software via USB-to-RS485 converter to configure protection settings(pickup levels,time delays),assign relay outputs,and download firmware.

Ensure CT wiring follows polarity rules for accurate differential calculations.Perform regular functional tests using secondary injection test sets to verify trip logic and timing.

Routine maintenance includes visual inspection,terminal tightening,and reviewing event logs.The solid-state design requires no calibration under normal conditions.

We provide full lifecycle support:engineering drawings,FAT/SAT procedures,training,and technical consulting.Every DEIF GPU 2 GS is factory-tested for accuracy and reliability.Contact us for a complete generator protection and power management solution tailored to your marine,industrial,or emergency power needs.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: