Description

Application Scenarios

At a coal-fired power plant in Germany,operators experienced frequent spurious trips due to unreliable digital signal transmission between field sensors and the DCS.The legacy I/O modules lacked sufficient isolation and were susceptible to electrical noise from high-power equipment.After upgrading to the ABB IOP351,the facility achieved stable signal integrity across all 32 input channels.The IOP351’s galvanic isolation and robust filtering eliminated false alarms caused by ground loops and EMI.During a turbine startup sequence,the module accurately captured all auxiliary equipment status signals,preventing unnecessary delays.This case highlights how the IOP351 addresses critical pain points:signal reliability in electrically noisy environments,support for safety-critical monitoring,and integration into large-scale DCS architectures.Whether in thermal power plants,water treatment facilities,or petrochemical complexes,the IOP351 serves as a dependable gateway for digital field data.

Parameter

Main Parameters Value/Description

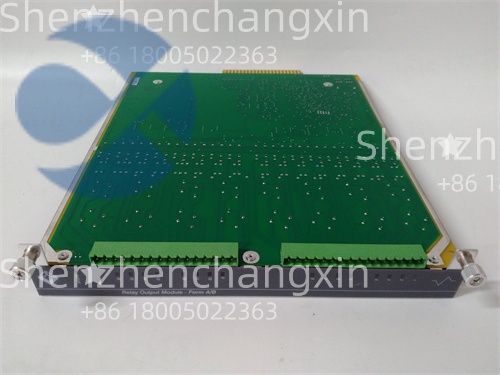

Product Model IOP351

Manufacturer ABB

Product Category Digital Input I/O Module

System Compatibility ABB Symphony®Plus,Advant OCS,Symphony Harmony

Function 32-Channel 24V DC Digital Input

Input Voltage 24V DC(nominal),range typically 18–30V DC

Signal Type Dry contact or wetted 24V DC(TTL-compatible)

Isolation Galvanic isolation(channel-to-channel and field-to-logic)

Sampling Rate Fast scan capability(<10 ms per channel)

Status Indication Individual LED per channel(ON/OFF),module health LEDs

Redundancy Support Yes–compatible with redundant Station Bus configurations

Operating Temperature 0°C to+60°C(industrial grade)

Installation Method DIN rail mount,connects to terminal base(e.g.,IBPxx series)

Communication Interface Station Bus(via IOLINK or SCANDIS)

Standards Compliance IEC 61000(EMC),CE,UL,CSA

Technical Principles and Innovative Values

Innovation Point 1:The IOP351 integrates an embedded microprocessor that preprocesses digital inputs,reducing the load on the main controller and enabling faster response times for time-critical applications like emergency shutdowns.

Innovation Point 2:With full galvanic isolation across all 32 channels,the IOP351 prevents ground loops and suppresses electromagnetic interference(EMI),ensuring signal accuracy in high-noise environments near motors,transformers,and switchgear.

Innovation Point 3:Designed for redundancy,the IOP351 supports dual Station Bus connections,allowing uninterrupted operation during network failures—essential for N+1 safety systems in power plants.

Innovation Point 4:The module supports hot-swap replacement;it can be removed and replaced without powering down the system,minimizing downtime during maintenance or fault recovery.

Innovation Point 5:Each channel features a dedicated LED indicator,enabling rapid visual diagnostics—technicians can instantly identify active or faulty signals without accessing software tools.

Application Cases and Industry Value

During a major DCS upgrade at a combined heat and power(CHP)plant in Sweden,engineers replaced outdated I/O hardware with the ABB IOP351 to improve system reliability.The module was deployed to monitor boiler feedwater pump statuses and burner management system interlocks.After implementation,the number of nuisance alarms dropped by 75%,and system availability increased by 2.3%.In another application,a wastewater treatment facility in Canada used the IOP351 to monitor 32 level switches across multiple tanks.Its fast scan rate ensured timely detection of overflow conditions,preventing environmental incidents.These cases underscore the IOP351’s value in enhancing operational safety,reducing unplanned outages,and supporting long-term asset management in mission-critical infrastructure.

Related Product Combination Solutions

IBP351:Terminal Base Unit–Provides physical mounting and wiring interface for IOP351.

IOP352:32-Channel Digital Output Module–Complements the IOP351 for complete DO functionality.

IOL321:I/O Link Coupler–Connects IOP351 to the Station Bus in Symphony Plus racks.

AC 800M:Advanced Controller–Central processor that communicates with IOP351 for logic execution.

IOP331:Analog Input Module(8-channel)–Used alongside IOP351 for mixed-signal I/O systems.

IOP353:16-Channel Relay Output Module–Ideal for driving contactors and annunciators.

ABB MMS6000:Machinery Protection System–Integrates with IOP351 for turbine safety interlocks.

ABB SPAJ 140C:Protection Relay–Shares status signals via IOP351 into the DCS for centralized monitoring.

Installation,Maintenance,and Full-Cycle Support

The ABB IOP351 installs directly onto a DIN rail using a compatible terminal base(e.g.,IBP351),which provides screw or spring-clamp terminals for field wiring.Before installation,ensure the Station Bus is configured and powered down if not using hot-swap.Align the module with the base and secure it with the locking mechanism.Once powered,the module initializes automatically and appears in the DCS configuration(e.g.,PCM600 or Control Builder M).No manual addressing is required—the IOP351 is recognized via backplane communication.

Routine maintenance includes periodic inspection of LEDs,cleaning of ventilation slots,and verification of terminal tightness.Due to its solid-state design,the IOP351 has a long service life and high MTBF(Mean Time Between Failures).In case of failure,the module supports hot-swap replacement in redundant systems,ensuring continuous operation.

Our technical team offers comprehensive lifecycle support,including:

Pre-engineering consultation and system design

On-site commissioning and configuration

Firmware updates and diagnostic services

Spare parts provisioning and obsolescence management

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: