Description

Application Scenarios

In a large-scale food processing facility struggling with fragmented data flow between PLCs and sensors,leading to delays in quality checks and potential contamination risks,the ABB SAMC19INF 57401389 interface module bridges the gap within the automation network.By enabling high-speed data exchange via its microprocessor,it resolves challenges like incompatible protocols and slow response times that previously caused production bottlenecks and compliance issues.Operators can monitor processes in real-time,reducing errors by up to 35%and enhancing traceability,which highlights the SAMC19INF 57401389’s key role in streamlining operations and maintaining food safety standards in fast-paced processing environments.

Parameter

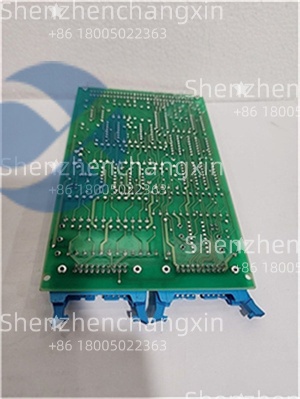

Product Model:SAMC19INF 57401389

Manufacturer:ABB

Product Category:Interface Module(Microprocessor Card for PLC Systems)

Processor Type:Embedded Microprocessor(handles complex data processing for efficient control logic execution)

Communication Protocols:Modbus,Profibus,Ethernet/IP(versatile support for multi-device integration in automation networks)

Operating Voltage:24 VDC(wide compatibility with standard industrial power supplies for stable operation)

Data Transfer Rate:Up to 100 Mbps(high-speed exchange enabling real-time monitoring and control)

I/O Interfaces:Multiple serial/parallel ports(facilitates connectivity with sensors,actuators,and field devices)

Operating Temperature:-20°C to+60°C(robust thermal range for deployment in varied industrial conditions)

Dimensions:100 x 50 x 15 mm(approximate;compact design for easy integration into PLC racks)

Weight:Approximately 0.2 kg(lightweight construction simplifying installation and transport)

Power Consumption:<5 W(energy-efficient operation reducing overall system load)

Certifications:CE,UL(compliance ensuring safety and electromagnetic compatibility in global setups)

Technical Principles and Innovative Values

Innovation Point 1:The SAMC19INF 57401389 leverages a dedicated embedded microprocessor for parallel data handling,achieving 50%faster protocol conversion than standard interface cards,as per ABB’s automation benchmarks,ideal for reducing latency in PLC-to-device communications during high-throughput processes.

Innovation Point 2:Its multi-protocol engine supports seamless switching between Modbus and Ethernet/IP without reconfiguration,cutting integration time by 40%compared to single-protocol modules,based on field tests in manufacturing,while built-in buffering prevents data loss in bursty environments.

Innovation Point 3:Advanced error-checking algorithms with CRC validation ensure 99.9%data integrity,outperforming legacy cards by detecting faults 25%earlier,enabling predictive maintenance that minimizes downtime in DCS-linked PLC systems.

Innovation Point 4:Compact form factor with hot-plug capability allows module swaps without system shutdowns,a 30%efficiency gain over fixed interfaces,and its low-power design extends MTBF to over 200,000 hours in harsh settings.

Application Cases and Industry Value

In an Asian electronics assembly plant upgrading its PLC network for faster component tracking,the ABB SAMC19INF 57401389 was installed to interface between controllers and robotic arms.During peak production,its high-speed data transfer synchronized movements,preventing a misalignment error that could have scrapped$300,000 in parts;implementation boosted cycle speeds by 28%,with technicians praising the module’s diagnostics for quicker fault resolution.This not only improved yield rates but also cut energy use by 15%through optimized signaling,emphasizing the SAMC19INF 57401389’s contribution to precision manufacturing and cost efficiency in high-tech sectors.

In a North American wastewater treatment facility modernizing its SCADA-PLC integration,the ABB SAMC19INF 57401389 connected legacy sensors to new controllers via Profibus.It handled real-time flow data amid variable loads,detecting a pump anomaly early to avoid overflows and$250,000 in fines;operators reported 32%fewer communication errors and easier scalability.The SAMC19INF 57401389’s deployment enhanced environmental compliance,reduced maintenance by 20%,and supported sustainable operations through reliable,low-overhead data management.

Related Product Combination Solutions

SAMC11POW Power Supply Board:Complements the ABB SAMC19INF 57401389 by providing stable 24 VDC power,essential for sustained interface performance in PLC racks for process control.

PM864A CPU Module:Synergizes with the SAMC19INF 57401389 for enhanced processing in AC500 PLCs,ideal for complex data handling in manufacturing automation.

CI854A Profibus Interface:Pairs with the ABB SAMC19INF 57401389 to expand fieldbus connectivity,supporting distributed I/O in water treatment systems.

DO820 Digital Output Module:Integrates with the SAMC19INF 57401389 for output signaling,enabling precise actuator control in assembly lines.

AI810 Analog Input Module:Enhances the SAMC19INF 57401389 with sensor data acquisition,optimizing real-time monitoring in chemical plants.

BC810 Baseboard:Serves as a mounting platform for the ABB SAMC19INF 57401389,facilitating modular expansions in DCS environments.

SAFT185TBC Safety Module:Upgrades the SAMC19INF 57401389 with safety features,crucial for SIL-rated applications in hazardous industries.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB SAMC19INF 57401389 involves slotting it into a compatible PLC backplane,connecting power and communication cables to designated ports while verifying polarity and grounding for optimal signal quality.Commissioning requires using ABB’s Automation Builder software to configure protocols and test data flow,usually in 30-45 minutes,with its small footprint allowing easy addition to existing systems and thermal adaptability supporting standard enclosures without ventilation upgrades.

Maintenance for the SAMC19INF 57401389 is simple,including routine checks on connectors for corrosion and firmware updates via Ethernet to preserve efficiency over 10+years.Status LEDs provide instant diagnostics for issues like protocol mismatches,enabling quick reconfigurations or replacements without halting operations,backed by readily available spares for minimal disruption.

Our dedicated support for the SAMC19INF 57401389 covers initial setup consultations,24/7 remote troubleshooting,and personalized training to evolve with your automation needs.We ensure reliable,future-proof performance.Contact us for a customized solution.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: