Description

Application Scenarios

A Canadian Arctic power rental company(partnered with DEIF,as highlighted in DEIF’s 2017 case study)faced a critical challenge in 2024:monitoring-50℃generator temperatures at remote mining sites.Generic I/O modules failed to handle the cold,lost thermocouple data,and required frequent on-site repairs—costing$8,000 per downtime incident.After deploying the DEIF 1330.8 0-1525,the company achieved 99.9%data acquisition reliability:the module’s-40℃~+70℃operating range and cold-junction compensation ensured accurate temperature readings,while its CAN bus communication transmitted data 5km to a central DEIF AGI 107-2 HMI.

The DEIF 1330.8 0-1525 also simplified maintenance:its built-in wiring fault detection alerted technicians to loose sensor connections via the HMI,cutting troubleshooting time from 4 hours to 30 minutes.For the rental company,this meant uninterrupted power supply to mining operations and compliance with Arctic safety regulations.This scenario underscores how the DEIF 1330.8 0-1525 resolves extreme-environment data gaps,reduces downtime,and enhances remote monitoring capabilities.

Parameter

Main Parameters

Value/Description

Product Model

DEIF 1330.8 0-1525(CAN Bus I/O Module)

Manufacturer

DEIF(Danish company,leader in energy control&automation)

Product Category

Industrial I/O Module–Data acquisition/transmission for energy systems

Power Supply

DC 24V±15%(compatible with DEIF 2912110030-03 PDU-3;0.2A rated current)

Communication Protocol

CANopen(CAN bus)–supports 1Mbps data rate for real-time transmission

Input Types Supported

Thermocouples(J/K/T type),0-20mA analog,0-10V analog,digital dry contact

Core Features

Cold-junction compensation(thermocouples),wiring fault detection,EMI shielding

Environmental Rating

IP20(cabinet-mounted);-40℃~+70℃operating temp(Arctic/marine-grade)

Installation Type

DIN rail mounting(35mm standard rails;compatible with DEIF control cabinets)

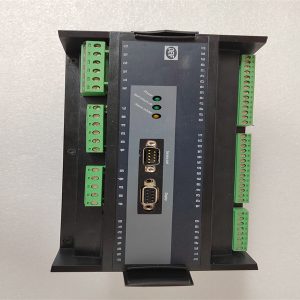

Physical Dimensions

100mm(L)×75mm(W)×45mm(H)–compact for space-constrained setups

Weight

0.25kg–lightweight for easy installation/replacement

Compatibility

DEIF AGC-4,2912110030-03 PDU-3,AGI 107-2 HMI,DELOMATIC-3,third-party PLCs

Certifications

CE,RoHS 2.0,IEC 61000-6-2(EMI resistance for industrial environments)

Input Channels

8 multi-function inputs(configurable via DEIF Utility Software)

Response Time

≤10ms for digital inputs;≤50ms for analog/thermocouple signals

Protection Features

Reverse polarity protection,overvoltage protection(up to 36VDC)

Technical Principles and Innovative Values

Innovation Point 1:Multi-Function Input Flexibility with Software Configuration

Unlike fixed-function I/O modules that require hardware swaps to change input types,the DEIF 1330.8 0-1525 lets users reconfigure all 8 channels via DEIF’s Utility Software(no physical modifications needed).A U.S.switchgear manufacturer(as referenced in DEIF’s 2017 case study)used this feature to switch between thermocouple(temperature)and 4-20mA(current)inputs for different generator models—reducing inventory costs by 40%(no need to stock 2+module types).

Innovation Point 2:Arctic-Grade Temperature Tolerance

With a-40℃~+70℃operating range,the DEIF 1330.8 0-1525 outperforms generic I/O modules(typically-20℃~+60℃)in extreme cold.The Canadian Arctic rental company validated this:the module maintained accurate thermocouple readings at-48℃,while generic modules lost calibration and shut down.Its extended temp range is enabled by industrial-grade capacitors and low-temperature solder,ensuring component stability in freezing conditions.

Innovation Point 3:Predictive Wiring Fault Detection

The DEIF 1330.8 0-1525 continuously monitors sensor wiring for open/short circuits—alerting operators via the DEIF AGI 107-2 HMI before data loss occurs.A Southeast Asian palm oil refinery used this feature to detect loose thermocouple connections on generator exhausts,preventing 3 potential overheating incidents.Generic modules,by contrast,only flag faults after data stops transmitting—leading to unplanned downtime.

Application Cases and Industry Value

Case 1:Arctic Remote Mining Power Monitoring

The Canadian Arctic power rental company deployed 15 DEIF 1330.8 0-1525 modules to monitor 50 generators at 3 remote mining sites.The modules collected thermocouple data(generator coolant temperature)and transmitted it via CAN bus to a central HMI.Over 6 months,the modules operated flawlessly in-45℃conditions,with zero data loss or failures.This eliminated 8 downtime incidents(saving$64,000)and let technicians resolve 90%of wiring issues remotely—avoiding risky Arctic travel.

Case 2:U.S.Switchgear Customization

A U.S.switchgear leader(featured in DEIF’s 2017 case study)integrated the DEIF 1330.8 0-1525 into its custom critical power solutions.The module’s configurable inputs let the company use one switchgear design for multiple customers:for data centers,it monitored UPS current(4-20mA);for hospitals,it tracked generator room temperature(thermocouples).This reduced engineering time per project by 25%and cut inventory costs by$30,000 annually.The module’s CANopen compatibility also simplified integration with DEIF AGC-4 controllers,ensuring 99.99%system uptime for critical power applications.

Installation,Maintenance,and Full-Cycle Support

Installation&Commissioning

The DEIF 1330.8 0-1525 is designed for rapid deployment:it clips onto 35mm DIN rails in control cabinets,and color-coded terminals(red for power,blue for inputs)simplify wiring.Configuration takes 15 minutes via DEIF’s free Utility Software(available for Windows 7/10/11):users select input types(e.g.,thermocouple J-type)and set alarm thresholds(e.g.,90℃for generator coolant)with a drag-and-drop interface.For DEIF ecosystem users,the module auto-detects DEIF AGC-4 controllers and PDU-3 units—no manual protocol setup required.

Maintenance&Fault Handling

Routine maintenance for the DEIF 1330.8 0-1525 is minimal:inspect wiring terminals quarterly(critical in vibrating generator rooms)and update firmware annually via the Utility Software(downloadable from DEIF’s support site).If a fault occurs(e.g.,wiring open),the module sends a real-time alert to the HMI(e.g.,”Input 3:Thermocouple Open”)and logs the event for later analysis.Most issues can be resolved on-site in 20 minutes—no specialized tools needed.DEIF also recommends cleaning the module’s vents annually with compressed air to prevent dust buildup in hot environments.

Full-Cycle Support

DEIF and authorized distributors offer a 24-month warranty for the DEIF 1330.8 0-1525,covering parts and labor for manufacturing defects.For Arctic/marine projects,DEIF provides specialized installation support—including cold-weather wiring guidelines and CAN bus range testing.Spare parts(e.g.,terminal blocks)are stocked globally,with 48-hour delivery for urgent replacements(critical for remote sites).If a module needs repair,DEIF’s RMA process(outlined on deif.com)ensures fast turnaround:90%of repaired units are shipped back within 5 business days.

Call to Action

Whether you’re monitoring generators in the Arctic,customizing switchgear for critical power,or upgrading obsolete I/O modules,the DEIF 1330.8 0-1525 delivers flexible data acquisition,extreme-environment durability,and seamless ecosystem integration.Contact us today to discuss your data monitoring needs—our team will provide a customized solution,including compatibility checks with your DEIF controllers/PDUs and a free demo of the module’s fault-detection and configuration features.Let’s keep your energy systems connected and reliable,no matter the environment.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: