Description

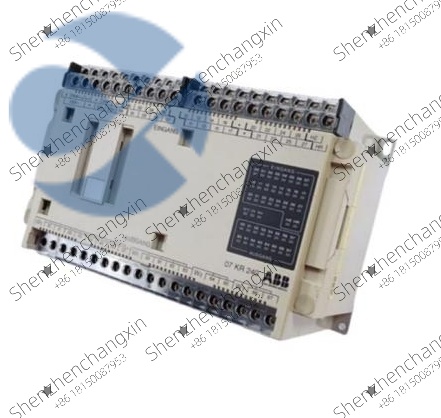

ABB 07KR240/GJV3072402R1 Technical Specifications

Item Parameters

Product Model 07KR240

Order Number/Part Number GJV3072402R1

Manufacturer ABB

Product Type: Three-Phase Magnetic Contactor

Series: ABB 07K Series

Number of Poles: 3-pole (Main Circuit)

Rated Operating Voltage (Ue): 690 V AC

Rated Operating Current (Ie)

AC-1 (Resistive Load): 240 A

AC-3 (Squirrel Cage Motor Start/Stop): 240 A

AC-4 (Motor Inching/Reverse Connection): 60 A | Conventional Thermal Current (Ith) | 240 A | Rated Insulation Voltage (Ui) | 1000 V AC | Control Coil Voltage (Uc) | 220-240 V AC (50/60 Hz), other voltages available | Control Power | Approximately 50 VA (Pulled-in), 20 VA (Maintained) ||Auxiliary Contacts|

Standard Configuration: 2 Normally Open (NO) + 2 Normally Closed (NC)

Expandable: Up to 4 NO + 4 NC (via accessories) || Mechanical Life | ≥10,000,000 Operations || Electrical Life (AC-3) | ≥100,000 Operations (at 240A/400V) || Dielectric Strength | 2500 V AC/1 minute (Main Circuit) || Protection Degree | IP20 (Body), IP40 (with Housing) || Mounting | 35mm DIN Rail or Screw Mounting || Operating Temperature | -25°C to +55°C (Operation); -40°C to +70°C (Storage) || Pollution Degree | 3 || Compliant Standards | IEC/EN 60947-4-1, UL 508, CSA C22.2 No. 14 || Arc Extinguishing System | Double Breakpoints + Metal Grid Interrupter, Rapid Arc Extinguishment || Overvoltage Category || III || Physical Dimensions | Approximately 120 mm (W) × 150 mm (H) × 120 mm (D) || Weight | Approximately 2.8 kg |

ABB 07KR240/GJV3072402R1 Product Overview

Hey friends, the ABB 07KR240 (part number GJV3072402R1) we’re talking about today is no ordinary relay; it’s the guardian angel of high-power motors! Imagine a large water plant with a 200kW pump starting and stopping dozens of times a day. Who can handle the 240-amp surge current? Who can cleanly and efficiently disconnect the circuit in the event of a fault? It’s the 07KR240 contactor!

The 07KR240, scientifically known as a three-phase electromagnetic contactor, is the “big switch” in motor control circuits. Rather than relying on manual operation, it uses a small control signal (such as a 24V PLC output) to drive an internal electromagnet, instantly closing or opening three pairs of main contacts, thereby controlling the start and stop of high-power motors.

Its greatest value lies in reliable starting and stopping and safe disconnection. In situations where adhesion could burn the motor or disconnection could damage the power grid, this contactor is a reassurance. Its 240A AC-3 rated current means it can frequently start and stop motors around 200kW. Its metal-grid arc extinguisher extinguishes the arc within milliseconds, preventing contact welding.

The 07KR240 belongs to ABB’s classic 07K series, widely used in water treatment, heating, ventilation and air conditioning (HVAC), industrial pumps, fans, and compressors. It’s indispensable for any application requiring remote control of high-power motors. Although soft starters and frequency converters are now available, contactors remain the “price-performance king” for simple start-stop control.

Main Features and Advantages

First, let’s talk about its superior electrical performance. The ABB 07KR240 operates stably at 690V, with a rated current of 240A under AC-3 loads, and can directly control motors up to 200kW (400V). Its dual-break design increases the arc path and improves breaking capacity.

Next, let’s talk about its powerful arc extinguishing capability. A metal-grid arc extinguishing chamber divides the arc into multiple segments, rapidly cooling and extinguishing it, ensuring that the contacts do not stick or spatter when interrupting high currents.

High reliability and long life are its core advantages. A mechanical lifespan of up to 10 million cycles means it can last 27 years even with 10 starts and stops per day! Its electrical lifespan exceeds 100,000 cycles (AC-3), far exceeding that of ordinary contactors. Auxiliary contacts provide status feedback, enabling control logic such as “self-locking” and “interlocking.”

Industrial-grade design. IP20 protection makes it suitable for installation in electrical control cabinets. It supports DIN rail mounting for easy assembly and disassembly. The control coil’s wide voltage range adapts to power grid fluctuations.

System safety is paramount. As a core component in motor control, its fast tripping capability effectively prevents overload and short-circuit accidents from escalating. When combined with a thermal relay (such as the T1 series), it forms a complete motor protection circuit.

The ABB 07KR240(GJV3072402R1) is a heavy-duty 3-pole electromagnetic contactor designed for motor starting and switching applications.Rated at 240A under AC-3 duty(up to 200kW at 400V),it features a robust construction with double-break contacts and a metal-grid arc chute for reliable arc extinction.Built to IEC/EN 60947-4-1 standards, it ensures safe and durable operation in demanding environments such as water treatment, HVAC, and industrial pumping systems. With a mechanical life of 10 million operations and an electrical life of over 100,000 cycles, it delivers long-term reliability for frequent motor start/stop control. Its 2NO+2NC auxiliary contacts support complex control logic, making it a critical component in industrial power distribution and motor management systems.

Application areas

This ABB The 07KR240 is primarily used in industrial systems requiring high-power motors, frequent starts and stops, and a high tolerance for failure. You’ll find it in water plant pump rooms, controlling fresh water and sewage pumps; in large building air conditioning rooms, it starts and stops chilled water pumps and cooling tower fans; in factory air compressor stations, it manages screw compressors; and in subway ventilation systems, it controls tunnel fans.

The 07KR240 is the standard configuration for any application requiring remote, frequent starting and stopping of high-power motors. Its genuine quality guarantees system stability, especially in power distribution cabinet modifications, spare parts replacement, and system maintenance projects.

Selection Guide/Purchasing Recommendations

Before installing the ABB 07KR240, please confirm three points:

First, are your motor power and current compatible? 240A AC-3 corresponds to approximately 200kW (400V). Avoid using a low-current contactor with a large motor; it will burn out.

Second, check the control voltage—the standard is 220-240V AC, but there are also options like 110V and 24V DC. Don’t buy the wrong coil voltage.

Third, avoid buying refurbished parts with “burned contacts, carbonized arc extinguishing chambers, and open coils”! Such contactors stick as soon as they close, effectively acting like ticking time bombs.

Our recommendation: Buy only those that have passed contact continuity, coil resistance, and insulation resistance tests to ensure safe operation.

Customer Case Study/Successful Application Analysis

Last year, a sewage treatment plant in Guangdong experienced welding on the main pump contactor contacts, preventing the motor from shutting down and nearly causing a burnout. They urgently replaced the contactor with our ABB 07KR240, and the system returned to normal. The customer commented, “A good contactor saved a million-dollar water pump. Genuine parts—truly reliable!”

Related Products

ABB T1 Thermal Overload Relay: Works with the 07KR240 to provide motor overload protection.

ABB MS325 molded case circuit breaker: Provides short-circuit protection.

Other ABB 07K series models: Such as the 07KR185 (185A) and 07KR300 (300A).

ABB auxiliary contact module: Expands the number of NO/NC contacts.

ABB mechanical interlock: Provides forward and reverse rotation control.

PLC control system: Provides control signals.

Motor control center (MCC) cabinet: Mounts the 07KR240.

ABB GJV3072402R2: May be a variant with different coil voltages.

Pre-installation preparation: Before replacing the ABB 07KR240, power must be disconnected, the electrical circuit must be tested, and the device must be locked out (LOTO). Ensure safety before any operation, as there is inductive current in the motor circuit. Before removing the old contactor, take photos and record the main circuit and control wiring. Install the new contactor on the DIN rail, ensuring it is securely fastened. Check that the main contacts are clean. When wiring, use appropriate wire diameters and tighten the terminals. Before applying power, manually test for smooth engagement.

Maintenance Recommendations: Check the main contacts for erosion and carbonization every six months. Clean the arc extinguishing chamber. Check the coil voltage for stability. A good contactor ensures smooth motor starts and stops.

Product Guarantee

At Shenzhen Changxin, we take every ABB 07KR240 contactor to the hilt. Upon arrival, we perform a visual inspection, main contact continuity test, coil resistance measurement, and insulation resistance test (≥10MΩ) to ensure smooth current flow. We offer a three-year warranty and replacement for non-intentional damage. We’re not in the business of quick profits; we’re committed to being the guardian of your power system. Trust us, we’ll stand up to you! [www.cnplcdcs.com]

The ABB 07KR240(GJV3072402R1) is a critical component in motor control systems, and at Shenzhen Changxin, we ensure every contactor is installation-ready. Each unit undergoes comprehensive electrical testing, including contact resistance, coil functionality, and insulation verification, guaranteeing reliable switching performance under full load. We supply genuine ABB parts and certified replacements, backed by a 3-year warranty and expert technical support. Whether you’re maintaining a water treatment plant or an industrial HVAC system, we deliver the quality and durability you need to prevent motor damage and unplanned downtime. Partner with us, and you’re not just replacing a contactor—you’re restoring the safety and efficiency of your entire motor control circuit.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: