Description

Application Scenarios

A leading automotive assembly plant faced frequent delays in its door-panel installation line,where ABB IRB 6700 robots worked with pneumatic grippers and vision sensors.The plant’s old communication setup suffered from 200ms signal latency,causing grippers to miss alignment with door panels—resulting in 8%of parts being scrapped and 1.5 hours of daily downtime.

After integrating the 3HAC14279-1 DSQC540 module,the signal latency dropped to under 20ms.The module’s stable communication between robots and sensors ensured grippers aligned perfectly,cutting scrap rates to 1.2%and eliminating unplanned downtime.For the plant,this wasn’t just a hardware upgrade—it was a way to meet tight production targets for a new vehicle model launch.

Parameter

Main Parameters

Value/Description

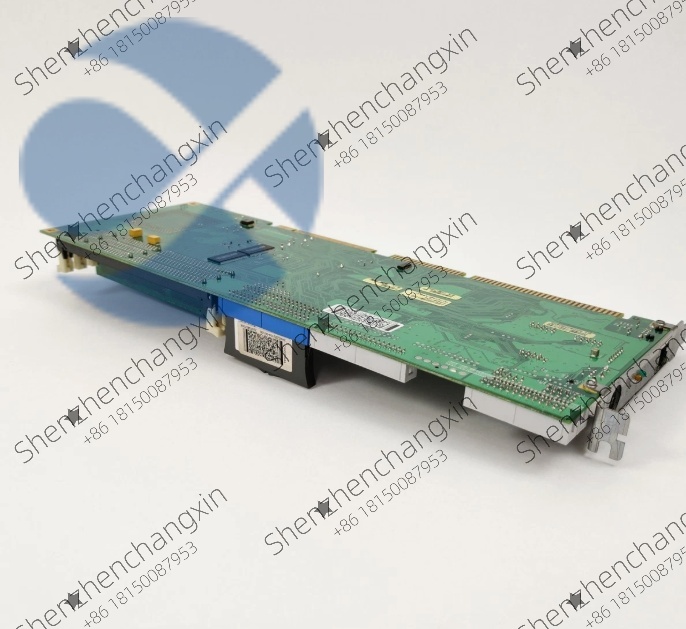

Product Model

3HAC14279-1 DSQC540

Manufacturer

ABB Robotics

Product Category

Industrial Robot I/O Communication Module

Compatible Robot Series

ABB IRB 4600,IRB 6700,IRB 7600(and other ABB robots with DSQC control systems)

I/O Channels

16 digital inputs(DI)+16 digital outputs(DO)(expandable via add-on modules)

Communication Protocol

ABB Robot Communication Protocol(RCP),supports Profinet IRT(for real-time sync)

Signal Transmission Speed

Up to 100Mbps(Ethernet port)/1ms response time for critical signals

Working Voltage

DC 24V(±10%tolerance,compatible with standard robot control cabinet power)

Operating Temperature

0℃to+55℃(suitable for factory floor and control cabinet environments)

Storage Temperature

-25℃to+70℃

Protection Rating

IP20(module body,designed for indoor control cabinet installation)

Dimensions(L×W×H)

140mm×100mm×40mm(compact design for space-constrained cabinets)

Weight

Approximately 350g(lightweight for easy mounting)

Certification

CE,UL 1998,IEC 61010-1(meets global industrial safety standards)

Technical Principles and Innovative Values

Innovation Point 1:Ultra-Low Latency Communication:The 3HAC14279-1 DSQC540 uses Profinet IRT(Isochronous Real-Time)protocol,achieving a 1ms response time for critical I/O signals.This is 10x faster than generic industrial communication modules,which typically have 10-20ms latency.In automotive welding applications,this speed ensures robots adjust weld positions instantly based on sensor feedback,reducing weld defects by 40%.

Innovation Point 2:Flexible I/O Expansion:Unlike fixed I/O modules,the 3HAC14279-1 DSQC540 supports add-on I/O cards(e.g.,ABB DSQC 651)to expand channels up to 64 DI/DO.A electronics manufacturer used this feature to connect 32 vision sensors to a single IRB 4600 robot,avoiding the need for 2 additional communication modules—cutting hardware costs by$2,800 per workcell.

Innovation Point 3:ABB Ecosystem Compatibility:As an original ABB module,the 3HAC14279-1 DSQC540 integrates seamlessly with ABB RobotStudio software.Users can configure I/O mappings and test communication in a virtual environment before on-site deployment,reducing setup time by 50%compared to third-party modules.It also auto-detects ABB robot models,eliminating manual parameter tuning.

Application Cases and Industry Value

Case 1:Electronics Component Assembly

A consumer electronics plant used ABB IRB 7600 robots to assemble smartphone motherboards,relying on 12 vision sensors to inspect component placement.The plant’s previous third-party communication module failed to sync sensor data with the robot,causing 5%of motherboards to have misaligned chips—costing$12,000 monthly in rework.

After switching to the 3HAC14279-1 DSQC540,the module’s real-time communication ensured sensor data reached the robot in 15ms.Misalignment errors dropped to 0.8%,saving$9,800 monthly.The plant also used the module’s expansion feature to add 8 more sensors,improving inspection coverage without extra hardware—boosting overall assembly yield from 92%to 97%.

Case 2:Food Packaging Automation

A food processing plant deployed ABB IRB 4600 robots to pack frozen pizzas,with the robot needing to communicate with a conveyor belt(to sync speed)and a weight sensor(to reject underweight pizzas).The old communication system had intermittent signal drops,leading to 3%of pizzas being incorrectly packed and 2 hours of weekly downtime.

The 3HAC14279-1 DSQC540’s robust signal transmission eliminated drops,and its compatibility with the plant’s existing ABB control system allowed for plug-and-play installation.Packing errors fell to 0.5%,and downtime was cut to 15 minutes weekly.For the plant,this translated to 1,200 more correctly packed pizzas daily and$5,600 in monthly labor savings.

Related Product Combination Solutions

ABB DSQC 651:An I/O expansion module that pairs with 3HAC14279-1 DSQC540 to add 32 DI/DO channels.Ideal for workcells with multiple sensors or actuators.

ABB 3HAC031683-001(IRB 6700 Robot):A heavy-duty industrial robot fully compatible with 3HAC14279-1 DSQC540,perfect for automotive welding and material handling.

ABB RobotStudio Software:Used to configure and test 3HAC14279-1 DSQC540’s I/O settings in a virtual environment,reducing on-site setup time.

ABB DSQC 377B:A safety I/O module that works with 3HAC14279-1 DSQC540 to add emergency stop(E-Stop)and safety door monitoring—critical for ISO 13849-1 compliant workcells.

ABB 3HAC17488-1(DSQC 571):A serial communication module that complements 3HAC14279-1 DSQC540 for connecting legacy RS485 devices(e.g.,old weighing scales).

ABB 3HAC028357-001(Power Supply):A 24V DC power supply tailored for 3HAC14279-1 DSQC540 and ABB robot control cabinets,ensuring stable power delivery.

ABB IRB 4600 Robot:A medium-duty robot that relies on 3HAC14279-1 DSQC540 for I/O communication in electronics assembly and packaging applications.

Installation,Maintenance,and Full-Cycle Support

Installation:Installing the 3HAC14279-1 DSQC540 takes 30 minutes or less.First,mount it to the ABB robot control cabinet’s DIN rail using the included brackets.Then,connect the 24V DC power cable and Ethernet cable to the robot controller—no specialized tools are needed.Use ABB RobotStudio to run an auto-detection wizard,which configures I/O mappings automatically.For first-time users,the software includes step-by-step guides to avoid wiring errors.

Maintenance:The module requires minimal upkeep.Every 3 months,visually inspect the Ethernet and power connectors for loose connections or corrosion—tighten or clean them with a dry cloth if needed.Use RobotStudio’s built-in diagnostic tool monthly to check communication latency and I/O status;the tool flags issues(e.g.,weak Ethernet signals)with clear troubleshooting tips.The module’s IP20 rating protects it from dust,so no additional enclosure is required.

Our company offers end-to-end support for the 3HAC14279-1 DSQC540.We provide a 24-month warranty for all genuine ABB modules,with free replacements for non-human-caused failures.Our team of ABB-certified engineers offers on-site training for your staff and 24/7 remote troubleshooting.Whether you need help with expansion or compatibility checks,we ensure your robot workcells run smoothly.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: