Description

Input Channels:6 independent channels

Maximum Frequency:100 kHz

Input Type:NPN/PNP,Push-Pull,Open Collector

Mounting Location:Mark VIe I/O Rack

Insulation Rating:IP20

Technical Specifications

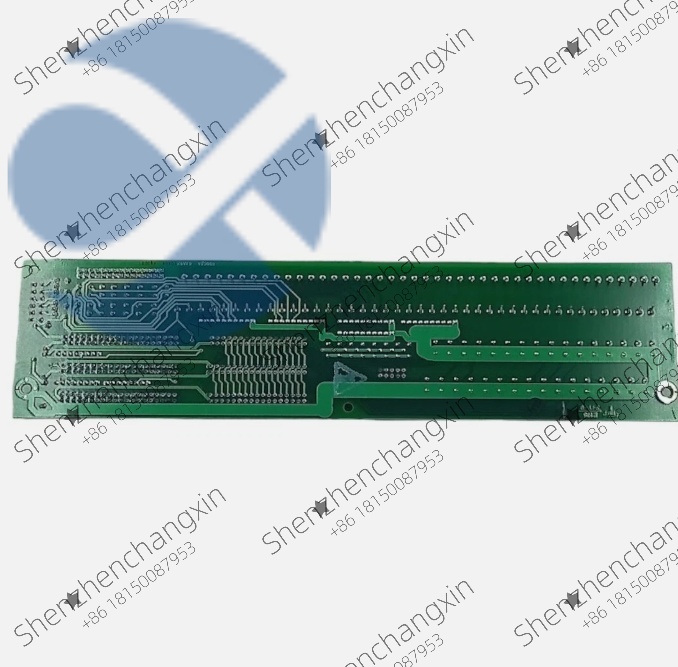

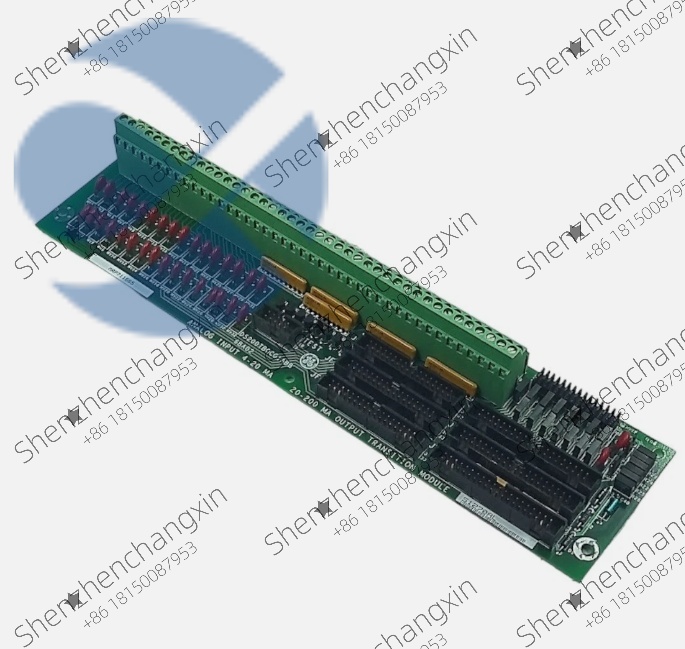

Product Model:DS200TBQCG1ABB

Manufacturer:General Electric(GE)

Product Type:Mark VIe High-SpeedCounter/Frequency Input Module

Series:Mark VIe Gas Turbine/Steam Turbine Control System

Function:High-speed pulse signal acquisition and processing

Input Channels:

Number of Channels:6 independent channels

Input Type:Supports various field signal sources,including NPN,PNP,push-pull,and open collector.

Input Voltage Range:Typical 5V DC to 24V DC(compatible with TTL,CMOS,and HTL levels).Maximum input frequency:100 kHz(per channel)

Counting modes:Frequency measurement,period measurement,speed calculation(RPM),and event counting.

Filtering:Configurable digital filters suppress signal noise and jitter.

Isolation:Group-to-ground isolation effectively suppresses common-mode interference.

Processing power:

A built-in processor independently performs frequency and speed calculations,reducing the burden on the host controller.

Configurable sampling rate and update period.Power Supply:Powered by the Mark VIe chassis backplane bus(typically+5V,+3.3V)

Operating Temperature:0°C to 55°C(32°F to 131°F)

Storage Temperature:-40°C to 85°C(-40°F to 185°F)

Relative Humidity:5%to 95%RH,non-condensing

Mounting:Standard 3U Eurocard(100mm x 160mm)plugs into the Mark VIe I/O chassis

Connection:Field wiring is connected via a dedicated terminal board or field terminal unit(FTU).The module itself connects to the chassis bus via the backplane.Indicators:Front panel LEDs indicate power(PWR),run(RUN),fault(FLT),and channel status(such as activity).

Weight:Approximately 0.6 kg

Certifications:CE,UL,CSA(meets industrial environment requirements)

Product Overview

The DS200TBQCG1ABB is the”precision timing officer”of the GE Mark VIe control system.It is a dedicated I/O module designed to acquire and process high-speed pulse signals.Its core mission is to accurately measure speed(RPM),frequency,and period—critical parameters for gas and steam turbine control and protection.

In modern turbomachinery,speed is a core variable throughout its lifecycle:

Startup:Accurately control the ramp rate to avoid excessive mechanical stress caused by excessive acceleration.

Grid-connected operation:Speed(frequency)must be synchronized with the grid.

Normal operation:Real-time speed monitoring for power control,vibration analysis,and other applications.

Overspeed protection:When the speed exceeds a preset safety limit,an emergency shutdown must be triggered within milliseconds to prevent catastrophic runaway accidents.This is the highest level of safety protection!The DS200TBQCG1ABB is designed for these demanding applications.It features six independent high-speed input channels,each capable of processing pulse signals up to 100kHz.This is sufficient to handle the high-frequency signals generated by speed probes(such as magnetoresistive and eddy-current probes)at the highest speeds of large gas turbines(e.g.,3000/3600 RPM).(For example,a 60-tooth gear at 3600 RPM generates a 3600 Hz signal,well below the 100kHz upper limit.)

It supports a variety of input signal types(NPN,PNP,etc.)and is compatible with mainstream speed sensors on the market.Dedicated circuitry and processors within the module independently perform frequency measurement,period calculation,and RPM conversion,transmitting the results in real time to the main controller(TCEC)via the Mark VIe’s high-speed bus.Its channel isolation design effectively resists complex field electromagnetic interference,ensuring measurement accuracy.Front-panel LEDs display the pulse activity status of each channel in real time,facilitating on-site commissioning and troubleshooting.

The DS200TBQCG1ABB is typically configured redundantly(for example,two modules simultaneously measure the same speed signal).The measurement results are used in critical overspeed protection logic,a vital component of unit safety.

Key Features and Advantages

The DS200TBQCG1ABB’s strengths lie in its high speed,precision,and reliability.

High speed is paramount.The 100kHz input frequency capability provides ample margin for measuring the speed of modern high-speed turbine machinery,ensuring complete and undistorted signal capture even at the highest speeds,avoiding measurement errors caused by undersampling.

Precision is key.Dedicated hardware counter circuits and configurable digital filters effectively filter out signal noise and contact jitter,providing stable and accurate frequency and speed readings.Independent processing reduces the burden on the main CPU and ensures real-time data processing.Accurate speed measurement is fundamental to smooth control and effective protection.

Reliability is paramount.As the front-end for critical safety functions such as overspeed protection,its reliability is paramount.Channel isolation enhances interference resistance.Hot-swappable support allows faulty modules to be replaced while the system is running,significantly improving system availability and maintainability.The original design ensures deep integration with the Mark VIe system and long-term stability.

The GE DS200TBQCG1ABB is a dedicated high-speed counter and frequency input module for the Mark VIe turbine control system.It features six independent input channels,each capable of processing pulse signals up to 100 kHz,making it ideal for the precise measurement of turbine speed(RPM),vibration frequency,and other critical high-frequency process variables.Designed for demanding applications,the DS200TBQCG1ABB supports various signal types(NPN,PNP,push-pull)and provides channel-to-ground isolation for robust noise immunity.Its primary and most critical application is in turbine overspeed protection systems,where its accurate and reliable speed measurement is essential for preventing catastrophic mechanical failure.By offloading high-speed counting tasks from the main controller and providing hot-swappable capability,the DS200TBQCG1ABB enhances system performance,safety,and maintainability in gas and steam turbine power generation.

Application areas

The application fields of DS200TBQCG1ABB are highly specialized and mainly focus on:

gas turbine Gas Turbine:Core Application.Used to measure gas turbine rotor speed,serving as a key input for startup control,load control,and overspeed protection.Typically configured redundantly.

Steam Turbine:Also used to measure rotor speed for control and protection functions.

Large Rotating Machinery:Such as large compressors,pumps,and generators,wherever high-precision,high-reliability speed monitoring and protection are required.

Combined Cycle Power Plants:Required for both gas and steam turbines.

Industrial Processes Requiring High-SpeedPulse Counting:Such as flowmeter(turbine flowmeter)signal acquisition and position feedback in motion control.

Selection Guide/Purchasing Recommendations

Choosing the DS200TBQCG1ABB requires careful consideration.First,ensure an exact model match.Verify it is the DS200TBQCG1ABB and pay attention to the hardware version.Second,ensure it is genuine.As a critical link in the safety chain,refurbished or non-genuine spare parts must never be used.Their performance and reliability cannot be guaranteed,potentially leading to serious accidents.Third,confirm signal compatibility:Understand the output type(NPN/PNP/voltage pulse,etc.)and signal frequency range of the on-site speed probe to ensure it falls within the module’s supported range.Fourth,spare parts strategy:For critical units,it is strongly recommended to stock at least one DS200TBQCG1ABB.A failure may result in loss of protection functions and requires immediate replacement.Fifth,technical support:After replacement,it is recommended that a professional engineer perform functional testing to verify the accuracy of speed measurement and the integrity of the protection logic.

Frequently Asked Questions(FAQ)

Q:Can the DS200TBQCG1ABB measure vibration?

A:Indirectly.It measures frequency.When connected to a vibration sensor(such as a magnetoresistive probe),it measures the vibration frequency(e.g.,1X or 2X the rotational frequency).To obtain vibration amplitude,a specialized vibration monitoring system(such as the Bently Nevada 3500)or an AI module that supports amplitude measurement is typically required.

Q:What is the difference between it and a standard digital input module?

A:Speedand functionality.Ordinary DI modules(such as the TCDAH1B)have slow scanning speeds(in the millisecond range)and cannot accurately capture high-speed pulses up to 100kHz.The DS200TBQCG1ABB features dedicated high-speed counting hardware,enabling precise frequency and period measurement and RPM conversion,which is beyond the capabilities of ordinary DI modules.

Q:Can the six channels simultaneously measure different speeds?

A:Yes.The six channels are independent and can be configured to measure the speeds of different shafts in the same unit or different devices.

Q:Is it hot-swappable?

A:Yes.While the Mark VIe system is operating normally,the DS200TBQCG1ABB module can be replaced while powered on.The system automatically recognizes the module and does not affect the operation of other modules.This is crucial for maintaining critical equipment.

Q:How is its measurement accuracy calibrated?

A:The module itself generally does not require field calibration.Its accuracy is guaranteed by its hardware and firmware.System-level”calibration”is achieved by setting the correct number of teeth or pulses per revolution in the configuration software(ToolboxST).For example,for a 60-tooth gear,the setting must be”60″in the software so that the module can correctly convert the measured frequency to RPM.

Related Products

DS200TCAH1A:Analog Input(AI)Module for signals such as temperature and pressure.

DS200TCDAH1B:Digital Input/Output(DI/DO)Module.

DS200SDCCG1A:Communication Interface Module.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: