Description

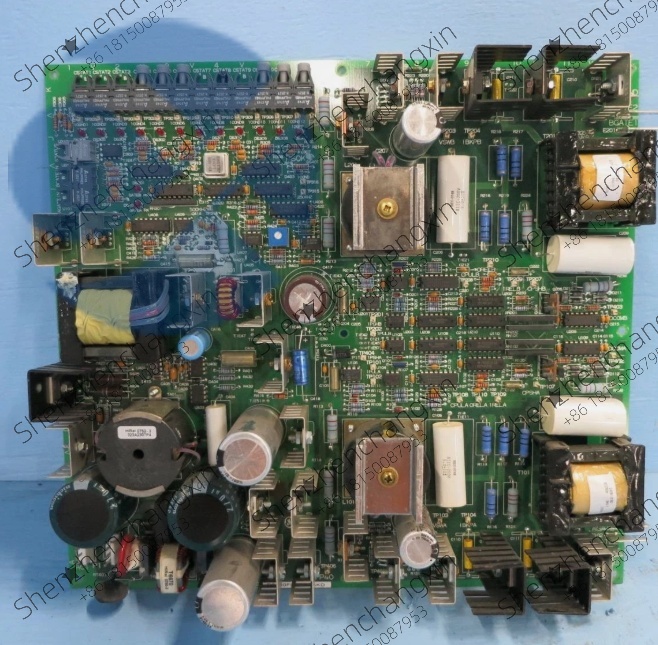

GE DS200FGPAG1A-KD Product Overview

The GE DS200FGPAG1A-KD is a”digital communication dual core”in the industrial DCS field,specifically designed to serve as a”digital dispatch+high-speed communication hub”for GE Mark series control systems.Don’t underestimate”digital+communication”—the valve status monitoring of thermal power plant steam turbines and the interlocking control of pump groups in chemical plant reactors all rely on it to collect digital signals.Inter-plant DCS data transmission is even more dependent on its fiber-optic communication capabilities.If module communication is interrupted,the entire system could become”blind.”This module is the key to connecting production processes.

In the thermal power plant’s steam turbine digital control system,the DS200FGPAG1A-KD is the”condition monitoring officer”:16 DI channels collect 12 steam turbine valve limit signals and 4 motor start/stop signals,while 8 DO channels control 4 alarm lights,2 interlocking shutdown relays,and 2 backup actuators.In one case,a steam turbine experienced a”high-pressure valve limit switch failure.”The module detected an abnormal DI signal within 0.4 seconds,immediately triggering an alarm via DO and sending a fault signal to the Mark VIe controller.The controller promptly reduced the load,preventing the risk of valve jamming.A standard module would have responded a second later,potentially causing the turbine speed to lose control.

Furthermore,the DS200FGPAG1A-KD’s fiber optic communication is extremely reliable.In a cross-plant DCS connection at a chemical park,it used fiber optics to connect the reactor workshop and the central control room,1.5 km apart.Data transmission latency was≤10ms,and communication remained uninterrupted even with numerous inverters in the workshop.Previously,using standard Ethernet cables,communication experienced at least two disconnections per month.After replacing this module,communication has remained fault-free for two consecutive years,eliminating the need for maintenance personnel to make daily on-site visits to troubleshoot communication issues.Main Features and Advantages

High-load digital input,smooth control:Ordinary digital modules have limited DI channels and low DO current,making them incapable of operating high-power actuators.The DS200FGPAG1A-KD’s 16-channel DI can simultaneously monitor the status of 16 devices.Its 8 DO channels,each with a 3A output,can directly operate small contactors(such as those for a 2.2kW motor)without the need for additional intermediate relays.Using this module in the control of belt conveyors in a steel plant has reduced the number of control modules per conveyor from two to one,halving the wiring and eliminating downtime caused by relay failures.

Fiber optic+Ethernet dual communication for stable and fast transmission:Many older plants use either Ethernet cables(poor interference resistance)or standard fiber optic modules(slow speeds)for inter-regional DCS communication.This module features both a fiber optic interface(for strong interference resistance and long transmission distance)and an Ethernet interface(for adapting to new systems).Communication modes can be switched with a single dial—fiber for inter-building communication and Ethernet for intra-workshop communication,eliminating the need for additional communication converters.At one refinery,it connects three equipment areas 1 km apart,achieving a data transmission rate of 100Mbps,five times faster than conventional communication modules.This reduces the latency of real-time monitoring in the central control room from 50ms to 10ms.

Strong interference resistance and overcurrent protection ensure durability and are not susceptible to fussiness:Industrial workshops are home to numerous inverters and motors,generating strong electromagnetic interference.Conventional modules are prone to false triggering,and overcurrent under load can burn out DO channels.This module,with its four-layer electromagnetic shielding,can withstand a 300kW inverter without false triggering.Each DO channel also features 5A instantaneous overcurrent protection,ensuring the module remains stable even if an actuator shorts.In the automotive welding workshop,this module controls the fixtures of welding robots.Even with frequent welding machine starts and stops,the DI signal has never been falsely reported,and the DO channel has never burned out due to a fixture short circuit.

Its wide temperature adaptability makes it suitable for harsh environments:outdoor control cabinet temperatures in northern winters can reach-25°C,while workshop temperatures in southern summers can reach 65°C.Conventional modules would have reported errors long ago.The DS200FGPAG1A-KD operates stably in temperatures ranging from-25°C to+70°C.In an outdoor oil pump control cabinet in an oil field,it continues to collect pump status and transmit data normally at-22°C in winter,making it much more reliable than modules that”stop working”at low temperatures.

The GE DS200FGPAG1A-KD excels as an industrial control module integrating high-performance digital I/O and dual-mode communication,tailored for critical Distributed Control Systems(DCS)in power,chemical,and metallurgical sectors.With 16 isolated digital inputs(DI)and 8 high-current digital outputs(DO,3A per channel),it eliminates the need for additional relays,streamlining control of valves,motors,and safety interlocks.

Its dual communication interfaces—fiber optic(100Mbps,up to 2km)and Ethernet(10/100Mbps)—ensure reliable,low-latency data transmission across distributed facilities,resisting electromagnetic interference(EMI)that plagues traditional copper-based systems.The fiber optic link is particularly valuable for long-distance connections between plant areas,while the Ethernet port seamlessly integrates with modern DCS controllers like GE Mark VIe.

Built to withstand harsh industrial conditions(-25°C to With a+70°C operating temperature and±8kV ESD protection,the module includes overcurrent protection for DO channels and robust EMI shielding,minimizing unplanned downtime.Compatible with GE’s CIMPLICITY and Proficy software,the DS200FGPAG1A-KD offers flexible configuration for both legacy(Mark V)and modern(Mark VIe)systems,making it ideal for retrofits and new installations alike.

Applications

In the power industry’s wind farm centralized control system,the DS200FGPAG1A-KD serves as the”data transmission hub.”The wind farm’s 10 wind turbines are dispersed within a 5km radius.The module’s DI interface collects information on each turbine’s start/stop status and generated power(digital signals),which is then transmitted to the central control room via optical fiber.Previously,wireless communication would disconnect during thunderstorms.After switching to this module,fiber-optic communication is unaffected by weather,and the data transmission success rate has increased from 95%to 100%.The central control room can adjust wind turbine operating strategies in real time,increasing wind power utilization by 3%and generating an additional 1.2 million kWh of electricity annually.

In the safety control system for hazardous chemical storage tanks in the chemical industry,the DS200FGPAG1A-KD serves as a”safety sentinel”:the module collects signals(DI)from the tank’s eight level switches and eight pressure switches.If the liquid level exceeds the upper limit,the module triggers an emergency shutoff valve and an alarm via DO.Its fiber-optic communication connects the tank farm and the central control room.Even in the complex electromagnetic environment and explosion-proof requirements of the tank farm,communication is seamless.Once,when the liquid level suddenly exceeded the warning level,the module triggered the shutoff valve within 0.5 seconds,preventing a hazardous chemical leak.A conventional module would have responded within a second,with disastrous consequences.The DS200FGPAG1A-KD is also very useful in the blast furnace feeding system of a metallurgical plant.The module collects the start and stop signals of the feeding system’s 12 conveyor belts and the status(DI)of the four silo gates.Eight DO channels control the belt motors and gate actuators.Previously,using a conventional digital module,the DO channels could not control the motor contactors,requiring the addition of 16 intermediate relays,which complicated wiring and caused frequent failures.After switching to this module,which directly controls the contactors and eliminates all relays,the number of failure points was reduced by half.The number of feeding system downtimes has dropped from three per month to one per quarter,increasing blast furnace production by 2%.

Selection Guide/Purchasing Recommendations

When choosing the DS200FGPAG1A-KD,first consider the signal type.If digital control is the primary focus and high-speed cross-region communication is required,this module is ideal.If analog processing is required,it should be used in conjunction with the GE DS200QTAG1ADC(analog module)rather than relying solely on it for analog processing.Next,consider your communication needs.For inter-building distances exceeding 100 meters,choose fiber optic communication.For short distances within the workshop,use Ethernet.Confirm the fiber type(multimode fiber)in advance and avoid purchasing the wrong single-mode fiber accessories.

During installation,note the following:Fiber optic interfaces must be properly dustproof(install fiber connector protective covers).Ethernet interfaces should not be placed together with high-voltage cables to prevent interference.When operating DO channels,do not exceed the rated current of 3A.High-power devices(such as 5kW motors)must include an intermediate relay.Finally,avoid buying second-hand or refurbished modules!The fiber optic transceivers in refurbished modules may be outdated,resulting in lower communication speeds and unsafe use in critical systems.Shenzhen Changxin[www.cnplcdcs.com]supplies all modules directly from the original manufacturer.Each module has an official GE serial number and offers fiber optic wiring and commissioning services,ensuring peace of mind.

FAQ

Q:Can the fiber optic interface of the GE DS200FGPAG1A-KD connect to single-mode fiber?

A:No!This module’s fiber optic interface is designed for multimode fiber(wavelength 850nm).It’s incompatible with single-mode fiber(wavelength 1310nm/1550nm).Forcing it to connect will result in signal loss.If single-mode fiber communication is required,you’ll need a fiber optic converter(multimode to single-mode)or the GE DS200FGPBG1A-KD(single-mode fiber version).Don’t mix them,as this will prevent communication and potentially burn out the fiber optic interface.

Q:The module’s DI channel isn’t receiving limit switch signals.How can I troubleshoot this?

A:Check the wiring first!Connect the”+”terminal of the DI channel to the positive 24V DC supply,the”-“terminal to the switch,and the other end of the switch to the negative terminal.Don’t connect them reversed.Also,check that the switch is functioning properly(use a multimeter to test for continuity when closed).If the switch is faulty,the signal cannot be acquired.If it is functioning properly,use a multimeter to test for 24V voltage at the module’s DI terminal.If there is no voltage,the module’s power supply may not be properly connected.If there is voltage but the signal cannot be acquired,the module’s DI channel is faulty and needs to be returned to the factory for repair.

Q:If the module’s DO channel has a contactor,and the contactor engages and then disengages,what should I do?

A:Check the contactor coil current!This module’s DO channel is rated at 3A per channel.If the contactor coil current exceeds 3A(for example,a contactor for a 10kW motor),the module’s overcurrent protection will be triggered,causing the DO channel to disconnect.You need to add an intermediate relay(such as the Omron G2R-3).The module controls the relay coil(current≤0.1A),and the relay contacts control the contactor.This prevents overcurrent and ensures stable contact closure.Avoid forcing overcurrent devices,as this can burn out the DO channels.

Q:The module and GE Mark VIe controller can’t connect via Ethernet.How can I troubleshoot this?

A:First,check the IP address!The module’s IP address must be on the same network segment as the Mark VIe controller(for example,the controller is 192.168.1.10,and the module is set to 192.168.1.20),with the same subnet mask(255.255.255.0).Then,check the network cable(using a cable tester).A broken cable won’t work.If both the IP address and cable are working,ping the module’s IP address from the controller.If it works,the protocol is incorrect(select TCP/IP).If it doesn’t,the module’s Ethernet interface is faulty and you need to replace the module.

Customer Case Study/Successful Application Analysis

A large thermal power plant has three 300MW steam turbine generator units using the GE Mark VIe system.The previous digital module suffered from slow communication and delayed DI response,resulting in at least one shutdown per month due to false module alarms,each costing over 800,000 RMB.After switching to the DS200FGPAG1A-KD,DI response time dropped from 1ms to 0.5ms,fiber optic communication latency was≤10ms,and false alarms completely disappeared.For two consecutive years,there were no shutdowns due to module issues.

One time,the low-pressure valve limit switch on Unit 2 suddenly malfunctioned.The module transmitted the fault signal to the controller within 0.4 seconds,immediately reducing the load to 200MW.A maintenance technician replaced the switch in one hour,without disrupting unit operation.With the previous module,the signal would have taken two seconds to transmit,potentially triggering a shutdown,resulting in an additional 800,000 RMB in losses.The power plant’s operations director said,”This module communicates quickly and responds accurately.After installing it,we no longer have to worry about false alarms!”

Another chemical company’s hazardous chemical storage area previously used standard modules and network cables for communication,resulting in at least one disconnection per month.

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: