Description

Application Scenarios

Imagine a massive utility power plant where a gas turbine is spinning at thousands of revolutions per minute.If the turbine exceeds its safe operating speed(overspeed),the resulting disaster could destroy the machine and cause a massive power outage.This is where the DS200PTBAG1ADC steps in.In the GE Mark V system,this board receives signals from the magnetic speed pickups mounted on the turbine shaft.It is designed to handle and condition these high-frequency pulse rate inputs,feeding them directly to the TMR(Triple Modular Redundancy)Protection Core for emergency overspeed protection.Furthermore,it aggregates other critical signals like generator voltage and current(from PTs and CTs)and flame detection.The reliability of the DS200PTBAG1ADC is literally what stands between normal operation and a catastrophic,unplanned shutdown,addressing the core pain point of reliable and immediate protective action.

Parameter

Technical Principles and Innovative Values

The DS200PTBAG1ADC is engineered for high-integrity signal transmission,a non-trivial task in a noisy power environment.

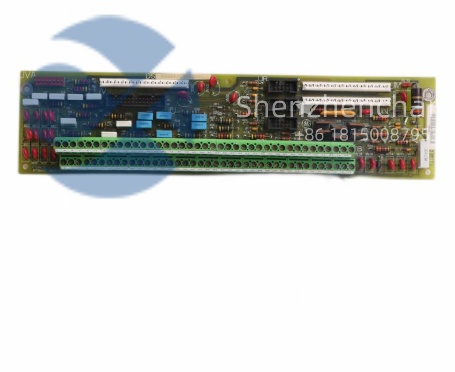

High-Integrity Signal Conditioning:The board is purpose-built to handle signals like magnetic pulse inputs,which are inherently susceptible to noise.It incorporates passive components(resistors,capacitors,etc.)and filtering techniques right at the termination point to clean up the signal before it reaches the sensitive I/O processors.This signal integrity is paramount for accurate overspeed detection.

Centralized Protection Aggregation:Unlike other I/O boards,the DS200PTBAG1ADC centralizes critical protection signals,including signals written to the Turbine Trip(TCTG)board.By grouping these safety-critical I/Os on one dedicated board,the GE Mark V system isolates the protection function,enhancing its reliability and independence from the main control loop.

Revision Control for Longevity:The”ADC”suffix indicates a specific revision level.In the Mark V world,knowing the revision of a board like DS200PTBAG1ADC is vital for compatibility and spares management.This system allows for functional improvements over time while maintaining backward compatibility with the core system architecture.

Application Cases and Industry Value

In a petrochemical plant,a set of critical compressors was driven by a GE gas turbine controlled by a Mark V system.The plant operators needed to constantly monitor the turbine’s shaft speed and bearing temperatures.The DS200PTBAG1ADC was integral,serving as the main interface for all primary and emergency overspeed pickups.During a routine pre-start check,a technician noticed a discrepancy in the speed signal.The diagnostic features relayed through the DS200PTBAG1ADC immediately flagged an issue with the magnetic pickup wiring termination.Because the system was designed with the integrity of the DS200PTBAG1ADC at its core,the fault was isolated and resolved immediately.The plant successfully started the turbine and achieved full production shortly after.This incident underscored the DS200PTBAG1ADC’s contribution to predictive maintenance and enhanced production safety by providing a reliable signal path for critical protective actions.

Related Product Combination Solutions

The DS200PTBAG1ADC always works in concert with the main Mark V protective core components:

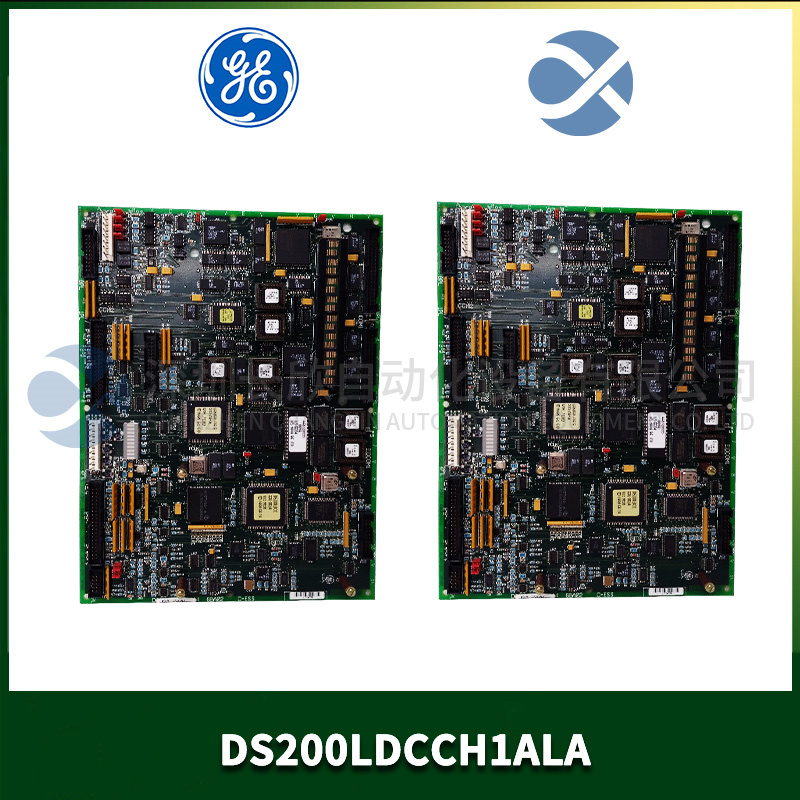

DS200TCEBG1:The TCEB(Turbine Control Enhancement Board)is the actual I/O processor board that connects directly to the DS200PTBAG1ADC and processes the high and low-pressure shaft speed signals.

DS200TCTGG1:The TCTG(Turbine Trip and Generator Breaker Board)is the crucial board that reads external trip signals and writes trip outputs via the DS200PTBAG1ADC.

DS200PTBAG1A/B:These are earlier revisions of the same Protection Termination Module.The DS200PTBAG1ADC is a later,often preferred,revision due to its enhanced availability and compatibility.

DS200QTBAG1:Another family of termination boards(like DS200QTBAG1ADC)used in the Mark V system,but for different signal types(e.g.,analog/fuel flow)and processors.

DS200SLCCG1:The main controller board(Slave Core Controller)in the Mark V core,which works with the P core I/O boards like the DS200PTBAG1ADC.

Installation,Maintenance,and Full-Cycle Support

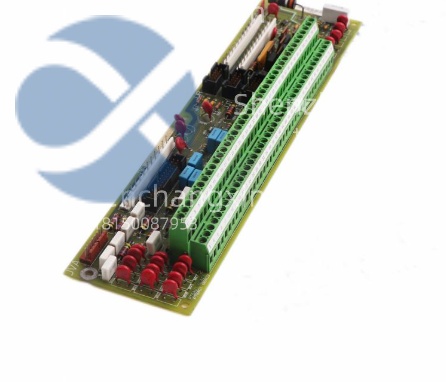

Installing the DS200PTBAG1ADC is about precision.As a terminal board,it has no active components,but its integrity is paramount.Installation involves sliding it into the designated slots within the Mark V control panel’s core section.All field wiring for the protective inputs is terminated directly onto the robust screw terminals of the DS200PTBAG1ADC.Maintenance is primarily visual inspection:ensuring all screw terminals are tight and free from corrosion,and that the board itself is clean and undamaged.The board’s simple,rugged design reduces the need for complex maintenance.For fault handling,while the DS200PTBAG1ADC is passive,a signal issue can often be traced back to a loose termination or a damaged trace on the board.When replacement is necessary,we provide only guaranteed genuine DS200PTBAG1ADC units.

We offer not just the DS200PTBAG1ADC module,but also the deep institutional knowledge required to install,commission,and troubleshoot it within your legacy Mark V system.Our expertise ensures you maintain the highest level of safety and reliability for your turbine assets.Contact us for a customized solution,whether you need a quick replacement or a full system audit.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: