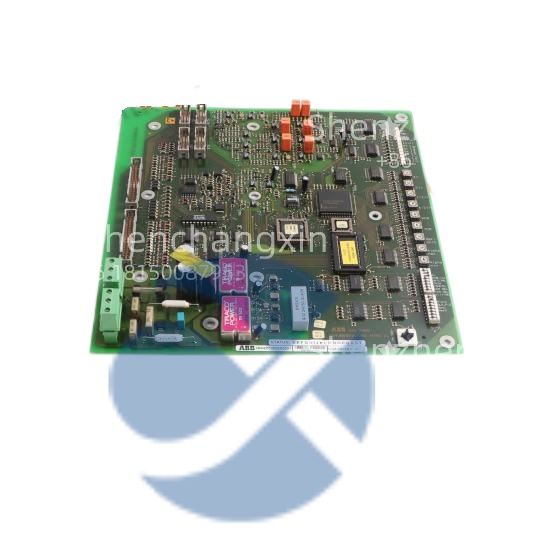

Description

Application Scenarios

At a chemical processing plant in Germany,frequent voltage fluctuations in the plant’s 230VAC supply caused unexpected shutdowns of the DCS system.The root cause was traced to aging power supplies unable to handle transient surges and brownouts.

Maintenance engineers replaced the obsolete power units with the ABB SF810 3BSE018501R1 in a redundant configuration across critical control racks.The SF810’s wide input voltage range(100–240 VAC)and built-in surge protection stabilized the 24VDC bus,eliminating nuisance trips.

Even during a major grid fluctuation,the redundant SF810 modules seamlessly took over,maintaining power to the CPU and I/O systems.Operators reported zero unplanned outages over the next 18 months,demonstrating how a robust power supply can be the foundation of system reliability.

Parameter

Main Parameters Value/Description

Product Model SF810 3BSE018501R1

Manufacturer ABB

Product Category DCS Power Supply Module

Output Voltage 24 VDC(nominal)–regulated and filtered

Output Current Up to 10 A–sufficient for full OCS rack load

Input Voltage 100–240 VAC,50/60 Hz–auto-ranging for global use

Power Output Approx.240 W–supports multiple modules per rack

Efficiency>85%–low heat generation and energy loss

Protections Overload,short-circuit,overvoltage,and thermal shutdown

Redundancy Support Yes–supports parallel operation with OR-ing diodes

Installation Method DIN rail mount(35mm)–standard industrial footprint

Cooling Natural convection–fanless design for high reliability

Operating Temperature 0°C to 55°C–suitable for control cabinets

Status Indicators LED for Power(PWR),Warning(WARN),and Fail(FAIL)

Compliance CE,UL,CSA–meets industrial safety standards

Technical Principles and Innovative Values

Innovation Point 1:High Reliability in Harsh Environments

The SF810 3BSE018501R1 is built with industrial-grade components and a fanless design,minimizing failure points.Its convection cooling and wide operating temperature range ensure stable performance in dusty,hot,or humid control rooms.

Innovation Point 2:Seamless Redundancy

When used in pairs,SF810 modules can be connected in parallel with external OR-ing diodes to provide redundant power.If one unit fails,the other automatically takes the full load without interruption—critical for process safety and uptime.

Innovation Point 3:Comprehensive Protection Circuitry

Integrated protections against overload,short circuit,overvoltage,and overheating prevent damage to downstream DCS modules.The SF810 automatically recovers once fault conditions are cleared,reducing maintenance intervention.

Innovation Point 4:Clean and Stable Output

The SF810 provides tightly regulated 24VDC with low ripple and noise,ensuring sensitive digital and analog modules operate accurately.This clean power reduces bit errors and improves signal integrity across the DCS network.

Application Cases and Industry Value

In a pulp and paper mill in Canada,the main DCS rack powered by an outdated 24V supply experienced random resets during startup of large motors.Voltage sags were affecting the CPU and I/O modules.

After installing the ABB SF810 3BSE018501R1,the system remained stable even during full plant startup.The SF810’s wide input range and internal buffering handled the sags without dropping output voltage.The mill reported a 95%reduction in control system anomalies,directly improving production uptime.

In a wastewater treatment facility,two SF810 units were deployed in redundancy to power the central control rack.During a lightning strike that took out one power supply,the second unit kept the system running.The FAIL LED on the damaged unit allowed technicians to identify and replace it quickly—without shutting down the plant.

This case highlights the SF810’s role not just as a power source,but as a key component in system resilience and fault tolerance.

Related Product Combination Solutions

SDCSCON3 3BSE018354R1:CPU module powered by SF810 for control processing.

SDCS-IOB-3 3BSE021252R1:Digital input module relying on SF810 for stable operation.

SDCS-DSL-4 3ADT200005R0001:Relay output module powered via the same 24VDC bus.

OCS Rack(ABB 3BSE018001R1):Standard chassis where SF810 is mounted alongside I/O and CPU.

SF800 3BSE018500R1:Earlier version of ABB power supply,compatible in some configurations.

Redundant Diode Module(ABB 3BSE018502R1):External OR-ing diode kit for SF810 redundancy.

24VDC Distribution Terminal Blocks:For clean power distribution within the cabinet.

Surge Protection Device(SPD):Installed upstream of SF810 for enhanced AC input protection.

Installation,Maintenance,and Full-Cycle Support

Installing the ABB SF810 3BSE018501R1 is straightforward:mount it on a 35mm DIN rail in the OCS cabinet,connect the AC input(100–240VAC),and link the 24VDC output to the backplane or distribution bus.For redundancy,connect two units via external OR-ing diodes to prevent back-feeding.

The LED indicators(PWR,WARN,FAIL)provide instant visual feedback on power status and fault conditions.Regular maintenance includes checking input/output connections for tightness and verifying that ventilation around the unit is unobstructed.

The SF810 is known for its long service life and minimal failure rate.However,as part of preventive maintenance,it is recommended to test output voltage and ripple every 2–3 years,especially in high-temperature environments.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: