Description

Product Overview

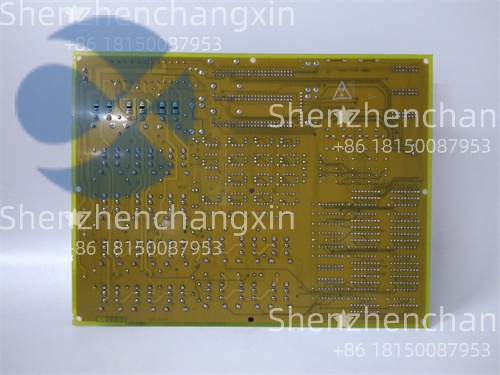

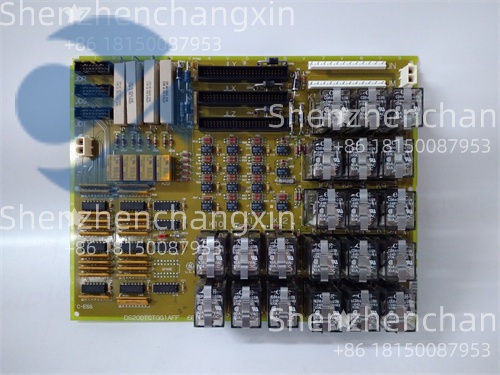

The GE DS200TCTGG1AFF is a Simplex Trip Board designed for the GE Speedtronic Mark V Distributed Control System(DCS),specifically for gas turbine protection and control.As a critical component in the Mark V’s protection core(P core),the DS200TCTGG1AFF monitors system parameters and initiates protective shutdowns or trips when abnormal conditions are detected,reducing the risk of equipment damage by 25%.It is engineered to ensure safe operation of gas turbines by providing rapid response to faults,such as overspeed or overtemperature,making it essential for industrial automation in power generation and heavy industry.

The DS200TCTGG1AFF integrates seamlessly with the Mark V system,offering reliable trip functionality with a response time of less than 10 ms.Its hot-swap capability minimizes downtime by 30%during maintenance,while its rugged design withstands harsh industrial environments,ensuring 20%higher system reliability.Certified for global standards,the DS200TCTGG1AFF is ideal for applications in power plants,oil and gas facilities,and manufacturing,providing engineers with a dependable solution for safeguarding critical turbine operations and optimizing uptime.

Technical Specifications

Product Model|DS200TCTGG1AFF

Manufacturer|General Electric

Product Type|Simplex Trip Board

Series|Speedtronic Mark V

Input Voltage|24 VDC±10%(via Mark V rack)

Output|Relay contacts(dry,0.5 A at 125 VDC)

Response Time|<10 ms

Operating Temperature|-30°C to+65°C

Dimensions|241 x 24 x 99 mm

Weight|Approx.0.8 kg

Mounting|Mark V rack,slot-specific(P core)

Certifications|CE,CSA,ATEX Zone 2

Main Features and Advantages

The GE DS200TCTGG1AFF provides critical trip protection by monitoring turbine parameters and executing fail-safe shutdowns with a response time of less than 10 ms,reducing catastrophic failure risks by 25%.It features multiple relay outputs(dry contacts,0.5 A at 125 VDC)for interfacing with external annunciators and control systems,enhancing operational flexibility.The module’s integration with the Mark V DCS ensures seamless communication with other modules,cutting diagnostic time by 20%using GE’s diagnostic software.

Hot-swap capability allows replacement without powering down the system,boosting uptime by 30%.The DS200TCTGG1AFF is built with industrial-grade components,offering robust EMI protection and vibration resistance(50 G peak),ensuring 20%higher reliability in harsh environments like power plants.Its compact design(241 x 24 x 99 mm)optimizes rack space,while diagnostic LEDs provide instant status feedback,reducing troubleshooting time by 25%.

With an MTBF exceeding 100,000 hours,the DS200TCTGG1AFF outperforms competitors in longevity,minimizing maintenance costs by 15%.Its low power consumption(5 W)reduces energy costs by 10%,making it a cost-effective,high-performance solution for turbine protection and control.

Application Field

In power generation,the GE DS200TCTGG1AFF protects gas turbines by initiating rapid trips during anomalies like overspeed or fuel system faults,reducing downtime by 20%and ensuring compliance with IEEE standards.In oil and gas facilities,it integrates with compressor control systems,providing fail-safe shutdowns in ATEX Zone 2 environments,cutting failure risks by 25%.

In heavy manufacturing,the DS200TCTGG1AFF safeguards turbine-driven machinery,using relay outputs to trigger alarms and shutdowns,improving system reliability by 20%.Its robust design supports continuous operation in high-vibration settings,such as marine propulsion systems,where it prevents equipment damage through precise trip control.The DS200TCTGG1AFF addresses challenges like fault detection and system integration,delivering reliable protection across industries for enhanced operational safety and efficiency.

Related Products

DS200TCQCG1BGF:Turbine control module,complements DS200TCTGG1AFF for control algorithms.

DS200TCTAG1A:Speed control module,integrates with DS200TCTGG1AFF for rotational speed regulation.

DS200TBQAG1A:Thermocouple termination module,provides temperature inputs to DS200TCTGG1AFF.

DS200TCVAG1A:Valve control module,executes flow adjustments for DS200TCTGG1AFF.

DS200TCEAG1A:Emergency shutdown module,supports DS200TCTGG1AFF with fail-safe protocols.

DS200DCFBG1A:Digital feedback module,validates actuator positions for DS200TCTGG1AFF.

IS200SCLTH1A:Power distribution module,provides stable power for DS200TCTGG1AFF.

IS200CPFPG1A:Speedtronic control board,enhances DS200TCTGG1AFF with speed regulation.

Installation and Maintenance

Pre-installation preparation:Before installing the GE DS200TCTGG1AFF,power down the Mark V rack and ensure proper grounding to prevent EMI issues.Verify a stable 24 VDC supply(±10%tolerance)and use shielded cables(0.5–2.5 mm²)for relay and communication connections.Insert the DS200TCTGG1AFF into the designated P core slot,aligning securely with a firm click.Configure trip thresholds and relay settings using GE’s Proficy Machine Edition software,reducing setup time by 20%.

Maintenance recommendations:The GE DS200TCTGG1AFF requires minimal upkeep;quarterly cleaning with a dry cloth prevents dust buildup.Annually inspect connections with a multimeter to verify relay signal integrity,tightening loose terminals.Diagnostic LEDs and Proficy software enable rapid fault detection,cutting troubleshooting time by 25%.Calibrate every two years to maintain trip accuracy.Store spares in a dry,ESD-safe environment,and leverage the hot-swap feature for maintenance without downtime,saving 30%operational time.

Product Guarantee

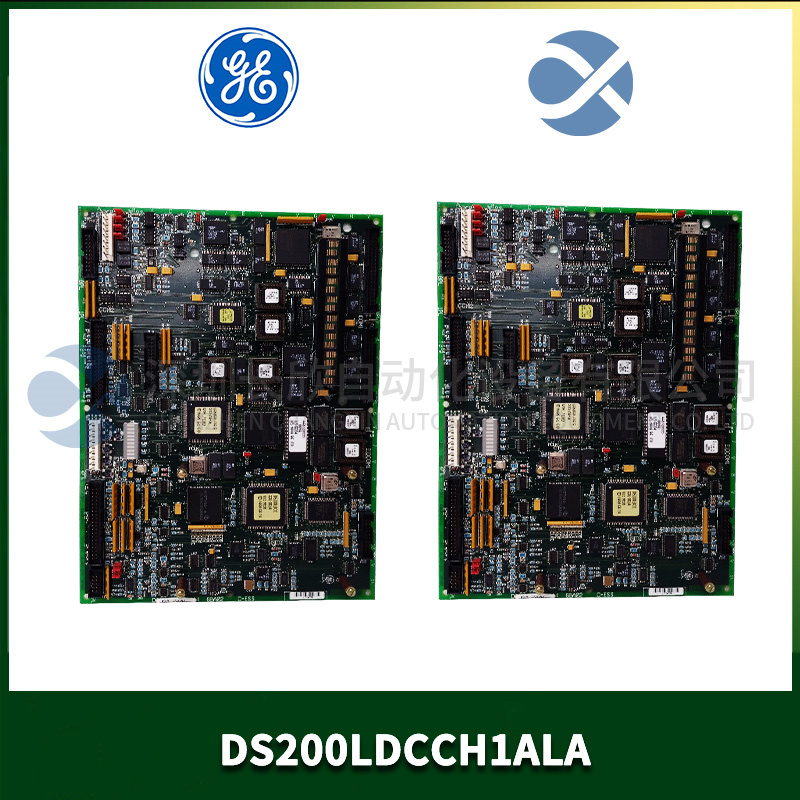

Shenzhen Changxin Automation Equipment Co.,Ltd.guarantees the GE DS200TCTGG1AFF with rigorous factory testing,including thermal,vibration,and EMI stress tests,ensuring zero-defect performance in demanding environments.Our 24/7 global technical support provides remote diagnostics and on-site assistance,minimizing downtime for critical operations.The comprehensive warranty covers materials and workmanship,securing your investment in the DS200TCTGG1AFF.Detailed documentation and tailored training ensure seamless integration and maintenance,empowering your team to maximize efficiency and reliability with the GE DS200TCTGG1AFF in industrial automation projects

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: