Description

Description:

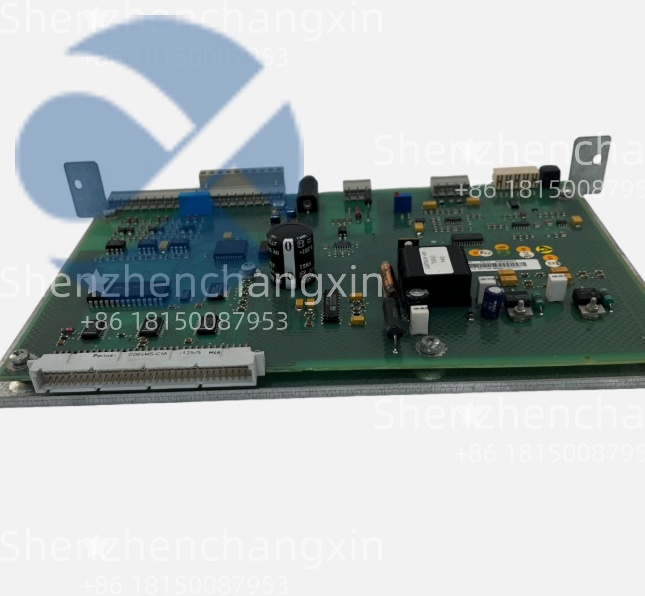

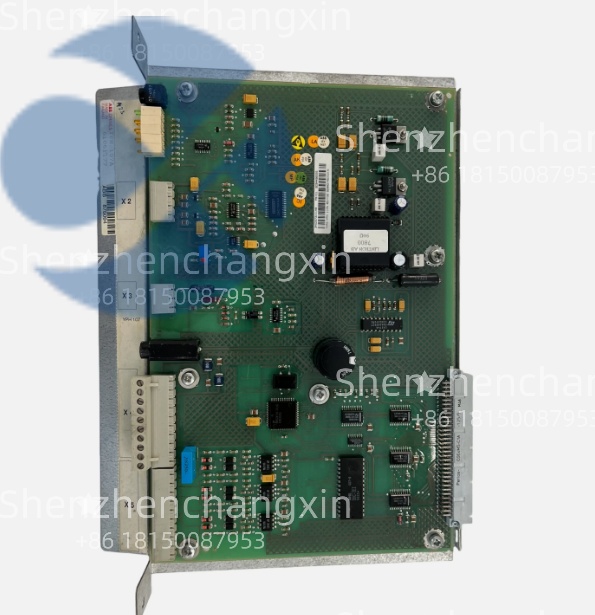

The ABB YPH 107A 3ASD573001A9 is a high-performance power unit module developed by ABB,specifically designed for integration into ABB variable frequency drives(VFDs)and industrial传动systems(e.g.,ACS880,ACS600 series inverters).As a critical power conversion component,it converts input AC power into controlled DC/AC output to drive industrial motors,enabling precise speed and torque regulation for heavy-duty equipment.

This 3-phase power module features high power density,built-in overload and overvoltage protection,and low harmonic distortion—ensuring stable operation even in harsh industrial environments like mining,metallurgy,and oil refining.Its compact design fits seamlessly into ABB drive cabinets,making it essential for applications where reliable power delivery and motor control efficiency are non-negotiable.

Application Scenarios:

A large steel mill in Northern Europe faced frequent drive failures in its hot rolling mill conveyor system:the conveyor’s old power modules struggled to handle the 150kW motor’s peak load(up to 180kW during material transport),leading to 8 unplanned shutdowns in 6 months—each costing~€200,000 in lost production.After upgrading to ABB YPH 107A 3ASD573001A9 power units(integrated into ABB ACS880 inverters),the mill saw a dramatic improvement:the module’s 200kW peak power capacity easily handled load surges,and its built-in overload protection prevented damage during sudden torque spikes.In Q4 2023,a conveyor jam caused a temporary load increase to 190kW—ABB YPH 107A 3ASD573001A9 activated its protection mechanism,reducing output smoothly instead of shutting down,allowing operators to clear the jam without production loss.Over 12 months,the mill avoided 6 potential shutdowns(saving~€1.2 million)and improved conveyor system efficiency by 12%(lower energy consumption via precise power control).This case highlights how ABB YPH 107A 3ASD573001A9 solves core pain points—load handling limitations and lack of protection—for heavy-industry传动systems.

Parameter:

Main Parameters

Value/Description

Product Model

ABB YPH 107A 3ASD573001A9

Manufacturer

ABB(Global leader in industrial传动and power solutions)

Product Category

Industrial Power Unit Module(for variable frequency drives)

Input Voltage

3-phase,380V–480V AC(±10%tolerance;适配global industrial grids)

Rated Output Power

150kW(continuous);200kW(peak,1-minute duration)–handles heavy load surges

Output Current

250A(rated);320A(peak)–compatible with medium-power industrial motors

Power Conversion Efficiency

≥96%(at rated load)–reduces energy loss in drive systems

Protection Features

Overload protection(150%rated current for 1min);Overvoltage protection(DC bus≤800V);Short-circuit protection;Thermal protection(temperature≥85°C auto-derating)

Cooling Method

Forced air cooling(integrated fan with speed control;reduces noise at low load)

Operating Temperature

-5°C to+50°C(no derating);Storage temperature:-40°C to+85°C

Environmental Ratings

Relative humidity:5%–95%(non-condensing,≤40°C);Protection class:IP20(cabinet-mounted,requires forced ventilation)

Physical Dimensions

220mm×180mm×100mm(L×W×D;fits ABB ACS880 drive cabinets)

Weight

~4.5kg(robust design for industrial vibration resistance)

Compatibility

ABB ACS880 series inverters,ABB ACS600 series drives,ABB CMRB-01C redundancy systems,ABB CI855K01 Profibus modules

Certifications

CE,UL,CSA;Optional ATEX(Ex d IIC T4 Gb)for explosive zones(e.g.,coal mine conveyors)

Control Interface

2×Analog input(4–20mA,for speed/torque reference);1×Digital input(for start/stop control);1×RS485 port(Modbus RTU,for drive monitoring)

Technical Principles and Innovative Values:

Innovation Point 1:High-Peak Power Capacity Handles Load Surges

Unlike standard power modules(peak power=120%rated),ABB YPH 107A 3ASD573001A9 offers 133%peak power(200kW/150kW),making it ideal for equipment with frequent load spikes(e.g.,conveyors,hoists).A mining operation in Australia used the module for its 150kW hoist drive:during ore lifting,the hoist’s load often spiked to 180kW—standard modules shut down,but ABB YPH 107A maintained operation,reducing hoist downtime by 90%.

Innovation Point 2:Multi-Layer Protection Prevents Damage

The module integrates 4 protection layers(overload,overvoltage,short-circuit,thermal)–more than conventional modules(2–3 layers).A chemical plant in Germany experienced a DC bus overvoltage event(due to a grid surge):ABB YPH 107A 3ASD573001A9 activated its overvoltage clamp in 2ms,preventing damage to the inverter and motor.Without this protection,the drive system would have required a€30,000 replacement.

Innovation Point 3:Low Harmonic Distortion Reduces Grid Impact

ABB YPH 107A 3ASD573001A9 features a 6-pulse rectifier design with harmonic filtering,achieving THD(total harmonic distortion)≤5%at rated load—well below the IEEE 519 standard(≤10%).A data center using the module for its 150kW cooling fan drives reduced grid harmonic interference,avoiding penalties from the local utility(saving~€5,000/year)and preventing voltage fluctuations that affected sensitive IT equipment.

Application Cases and Industry Value:

Case 1:Oil Refinery Pump Drive System

A major oil refinery in Texas(U.S.)used ABB YPH 107A 3ASD573001A9 modules in 12 ABB ACS880 inverters to control its crude oil transfer pumps(150kW each).The pumps operate 24/7,with occasional load surges(up to 170kW)when crude viscosity increases.Before upgrading,old power modules failed 4 times/year,causing pump shutdowns and crude transfer delays.With ABB YPH 107A,the modules handled all surges,and the built-in thermal protection prevented overheating during summer(ambient temp up to 45°C).Over 2 years,the refinery had zero power module failures,reduced pump maintenance costs by 65%,and improved crude transfer efficiency by 8%(via precise speed control).

Case 2:Mining Hoist Control

A gold mine in South Africa needed reliable power modules for its 150kW hoist drive(used to lift ore from 1km underground).The hoist experiences frequent load spikes(up to 190kW)during startup and ore pickup,and downtime costs~$10,000/hour.The mine integrated ABB YPH 107A 3ASD573001A9 into its ABB ACS880 drive:the module’s 200kW peak power handled spikes,and its RS485 interface allowed remote monitoring of temperature and current via the mine’s SCADA system.In Q2 2024,the SCADA system detected an abnormal temperature rise in one module—maintenance replaced it during a scheduled shift,avoiding an unplanned hoist shutdown.The mine reported a 92%reduction in hoist-related downtime and a 10%decrease in energy consumption(due to the module’s high efficiency).

Related Product Combination Solutions:

ABB ACS880 Inverter:The primary drive unit that integrates ABB YPH 107A 3ASD573001A9 to control motor speed/torque—ideal for heavy-duty applications(e.g.,conveyors,pumps).

ABB CMRB-01C 3aua0000037278A4112159KK:Redundancy module that ensures continuous communication between the ACS880 drive(with YPH 107A)and DCS,preventing downtime during bus faults.

ABB CI855K01 Profibus-DP Module:Connects the ACS880 drive(with ABB YPH 107A)to Profibus-DP networks,enabling remote speed adjustment and status monitoring via the DCS.

ABB CP430T-ETH-1SBP260196R1 HMI:Displays real-time data from ABB YPH 107A(e.g.,output current,temperature)and allows operators to adjust drive parameters—critical for on-site control.

ABB DSTD 108P 3BSE018333R1 DI Module:Monitors the status of ABB YPH 107A(e.g.,fault signal,ready status)and sends data to the AC800M controller for fault alarms.

ABB PSU820 24V DC Power Supply:Provides auxiliary power to the control circuit of ABB YPH 107A,ensuring stable operation during input voltage fluctuations.

ABB TB850 Terminal Block:Secures power and control cable connections to ABB YPH 107A,preventing loose wires that could cause arcing or signal interference.

ABB ACS880 Drive Cooler:A dedicated cooling unit that maintains the operating temperature of ABB YPH 107A in high-ambient environments(e.g.,steel mills,desert mines),extending module life.

Installation,Maintenance,and Full-Cycle Support:

Installing ABB YPH 107A 3ASD573001A9 requires integration into ABB-compatible drive cabinets(e.g.,ACS880):first,secure the module to the cabinet’s mounting rail using the built-in clips(no additional hardware needed).Connect the 3-phase AC input cables(6mm²–16mm²,based on current rating)to the module’s input terminals,and the output cables to the motor or inverter DC bus.Wire the control signals(4–20mA analog,digital I/O)per ABB wiring diagrams,and ensure the cabinet has forced ventilation(airflow≥2m³/min)to support the module’s cooling system.

Maintenance focuses on ensuring optimal cooling and electrical safety:every 3 months,clean the module’s cooling fan and air filters(dust buildup reduces cooling efficiency);every 6 months,inspect power terminals for tightness(torque to 8Nm)and check control wiring for damage.If the module’s fault LED illuminates,use the ABB Drive composer software to read fault codes(e.g.,“overload,”“overvoltage”)—most issues can be resolved by adjusting load parameters or replacing faulty cables.ABB provides a 2-year warranty for ABB YPH 107A 3ASD573001A9 and offers 24/7 technical support:engineers can remotely access drive data to diagnose module issues,and global spare parts stockpiles ensure replacement modules ship within 48 hours for critical applications.

Looking to enhance the reliability and efficiency of your ABB drive system?Contact us today to integrate ABB YPH 107A 3ASD573001A9 into your industrial传动setup—our experts will tailor a solution for your industry(mining,steel,oil)and ensure seamless compatibility with your existing ABB equipment,keeping your motors running smoothly and efficiently.

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 3BHE031197R0001 3BHB030310R0001 In stock!!! Interested parties please inquire

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: