Description

Product Overview

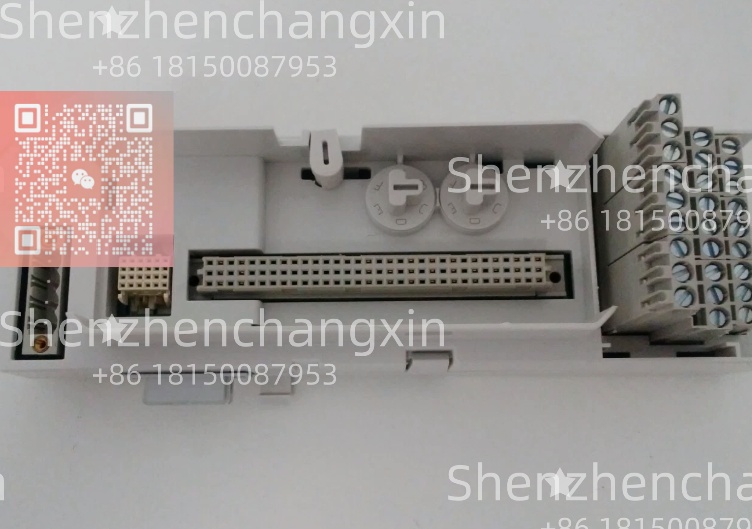

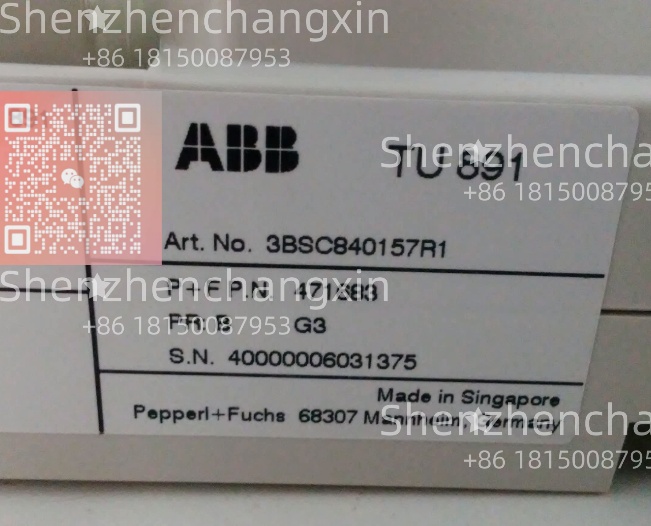

The ABB 3BSC840157R1(DSQC103)is a dedicated Safety Power Relay Module designed for integration within ABB’s S4C robot controller cabinets.This critical component,known as the DSQC103,plays a fundamental role in the robot system’s safety circuit,acting as the central hardware responsible for monitoring safety inputs and controlling the power delivery to the robot’s servo drives.Its primary function is to ensure that the robot can only operate when all safety conditions are met,and to safely cut power to the motors in the event of a safety-related event,such as an emergency stop(E-stop)being pressed,a safety door being opened,or a light curtain being breached.

The 3BSC840157R1 module is engineered to meet stringent industrial safety standards.It features dual-channel monitoring of safety devices(like E-stop buttons and safety gate switches)to provide redundancy and detect faults within the safety circuit itself.When the system is powered up and all safety conditions are satisfied(e.g.,E-stops are released,safety doors are closed),the DSQC103 energizes its internal safety relays,allowing 24V DC power to be sent to the individual servo drive units(amplifiers)for each robot axis.This state is often referred to as”enabling the drives.”If any safety input is triggered,the module immediately de-energizes these relays,cutting power to the drives and bringing the robot to a safe stop.The module typically includes status LEDs to indicate power,safety circuit status(OK/Not OK),and relay activation,providing crucial visual feedback for operators and maintenance personnel.The ABB DSQC103 3BSC840157R1 is thus a vital guardian of personnel and equipment safety in automated environments utilizing ABB robots like the IRB 2400,IRB 4400,and IRB 6400 series.

Technical Specifications

Product Model ABB 3BSC840157R1(DSQC103)

Manufacturer ABB

Product Type Safety Power Relay Module

Series/Platform S4C Robot Controller

Function Safety Circuit Control&Drive Power Enable

Safety Category Category 3,Performance Level d(PLd)or higher per ISO 13849-1

Input Voltage+24 V DC(nominal)

Controlled Output 24 V DC to Servo Drive Units(via relays)

Input Signals Dual-channel Emergency Stop(E-stop),Safety Door Switches,External Safety Devices

Output Signals Drive Enable Power(24V DC),Status Feedback to CPU

Relay Type Safety-rated,force-guided relays with positive opening contacts

Number of Relays Typically 2 main safety relays for redundancy

Status Indicators LED(s)for Power,Safety Circuit OK,Relay Output

Mounting DIN Rail(within S4C Cabinet)

Operating Temperature 0°C to+45°C(Cabinet Ambient)

Storage Temperature-25°C to+55°C

Humidity 5%to 95%RH,non-condensing

Approvals CE,UL,cUL,conforms to relevant safety directives(e.g.,Machinery Directive)

Main Features and Advantages

The ABB 3BSC840157R1 DSQC103 offers essential features that are paramount for safe and reliable robot operation.Its most significant advantage is compliance with high safety standards.By incorporating dual-channel monitoring and safety-rated relays with positive-guided contacts,the module ensures that a single fault within the safety circuit(like a welded relay contact or a broken wire)can be detected,preventing the system from falsely indicating a safe state.This redundancy is critical for preventing accidents in environments where humans and robots interact.

Another key advantage is its centralized and reliable safety control.The DSQC103 provides a single,well-defined point for managing the safety interlocks of an entire robot cell.This simplifies the design and verification of the safety system.Its robust design ensures dependable operation even in the electrically noisy environment of a robot control cabinet.The clear status indication via LEDs allows for rapid visual diagnosis of safety circuit status—whether the system is ready to run(safety circuit closed)or if a fault has been detected(safety circuit open).This speeds up troubleshooting during maintenance or after a safety event.Furthermore,the module is designed for easy integration and replacement within the standardized S4C cabinet architecture.Its plug-in nature means that if the module fails,it can be replaced relatively quickly,minimizing costly production downtime.The 3BSC840157R1 thus provides a trustworthy,standardized solution for implementing critical safety functions in ABB robotic systems.

Application Field

The ABB 3BSC840157R1 DSQC103 is an indispensable component in any industrial automation cell utilizing ABB S4C-controlled robots where personnel safety is a priority.Its primary application is in automotive manufacturing,particularly in body shops and paint shops,where IRB 2400 and IRB 4400 robots perform high-speed welding,painting,or material handling.In these environments,multiple operators may need access to the cell for loading parts,performing maintenance,or quality checks,making reliable safety interlocks essential.

It is also widely used in general industry applications such as machine tending,where operators load raw materials into CNC machines and unload finished parts,requiring safe access to the work area.In material handling and palletizing systems,safety doors and light curtains monitored by the DSQC103 prevent robot movement when personnel are within the hazardous zone.The module is crucial during robot programming,commissioning,and maintenance,allowing technicians to safely enter the cell by breaking the safety circuit,knowing that power to the motors is physically cut.The 3BSC840157R1 ensures that the robot cannot be inadvertently started while someone is inside its workspace,protecting workers from injury.By providing a certified and reliable method to control drive power based on safety inputs,this module is fundamental to creating safe,compliant,and efficient robotic workcells across diverse manufacturing sectors.

Related Products

ABB DSQC100 is a related module,sometimes used for different safety configurations or monitoring.ABB DSQC102 is another safety-related module that might interface with the DSQC103.ABB M2000 CPU(e.g.,3HAC3180-1)is the main controller that receives status feedback from the 3BSC840157R1.ABB DSQC611(e.g.,3HAC13389-2-07A)is an axis computer module that receives its 24V power through the enable signal from the DSQC103.ABB S4C Cabinet is the complete control enclosure housing the 3BSC840157R1.ABB IRB 4400 is a primary robot model that utilizes the DSQC103 for safety control.ABB 3HAC022675-001 is the typical cabinet power supply providing the 24V DC input to the DSQC103.ABB 3HAC027865-001 is a robot cable that carries the drive enable signal from the 3BSC840157R1 to the servo units.ABB 3HAC033979-001 is the standard teach pendant used to operate the robot system protected by the DSQC103.ABB DSQC380 is a digital I/O module that may be used to connect additional safety inputs to the system.

Installation and Maintenance

Pre-installation preparation:Before installing the ABB 3BSC840157R1 DSQC103,ensure the S4C robot controller cabinet is completely powered down and locked out(LOTO procedure)to eliminate electrical hazards.Verify that the designated DIN rail slot is available and the backplane connector is clean and undamaged.Check that all external safety devices(E-stops,door switches)are correctly wired and in their”safe”state(e.g.,E-stops released,doors closed)before powering up.Consult the S4C cabinet wiring diagrams to confirm the correct placement and connection points for the DSQC103 module.Handle the module with care,avoiding electrostatic discharge(ESD)by using a wrist strap if possible.

Maintenance recommendations:Regularly inspect the 3BSC840157R1 for physical damage and ensure the connectors are secure.Monitor the status LEDs during normal operation;a steady”OK”light indicates the safety circuit is closed and the system is ready.If the safety circuit fails to close(LED off or flashing),systematically check all connected safety devices(E-stops,switches)and their wiring for faults.The DSQC103 is designed to be a reliable,long-life component with no user-serviceable parts.If a fault is diagnosed within the module itself(e.g.,relays fail to energize despite a closed safety circuit),replacement is the standard procedure.Replacement involves powering down the cabinet,removing the faulty module,inserting the new 3BSC840157R1 into the correct slot,securing it,and powering up.The system should automatically recognize the module.Always follow ABB’s safety protocols when working with robot control systems.

Product Guarantee

Every ABB 3BSC840157R1 DSQC103 module offered is guaranteed to be a genuine ABB product,sourced through authorized and reputable channels,and verified to meet original specifications for safety and performance.We provide a comprehensive warranty that underscores our confidence in the authenticity and critical safety function of this component.Our commitment extends to offering dedicated technical support for compatibility verification,installation guidance,and troubleshooting assistance,ensuring you have the resources needed for a safe and correct deployment.We understand that the integrity of the safety system is non-negotiable in automated production.Therefore,we prioritize product authenticity,rigorous quality assurance,and fast,accurate fulfillment.The 3BSC840157R1 is not just a spare part;it is a cornerstone of your robot cell’s safety infrastructure,and we guarantee its quality and readiness to protect personnel and ensure compliance with safety regulations.

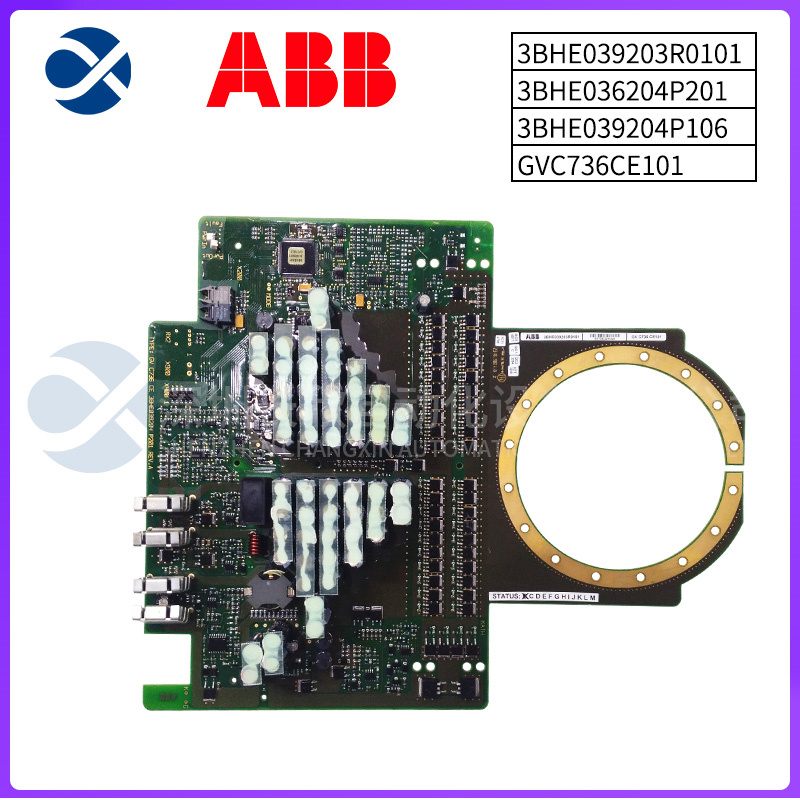

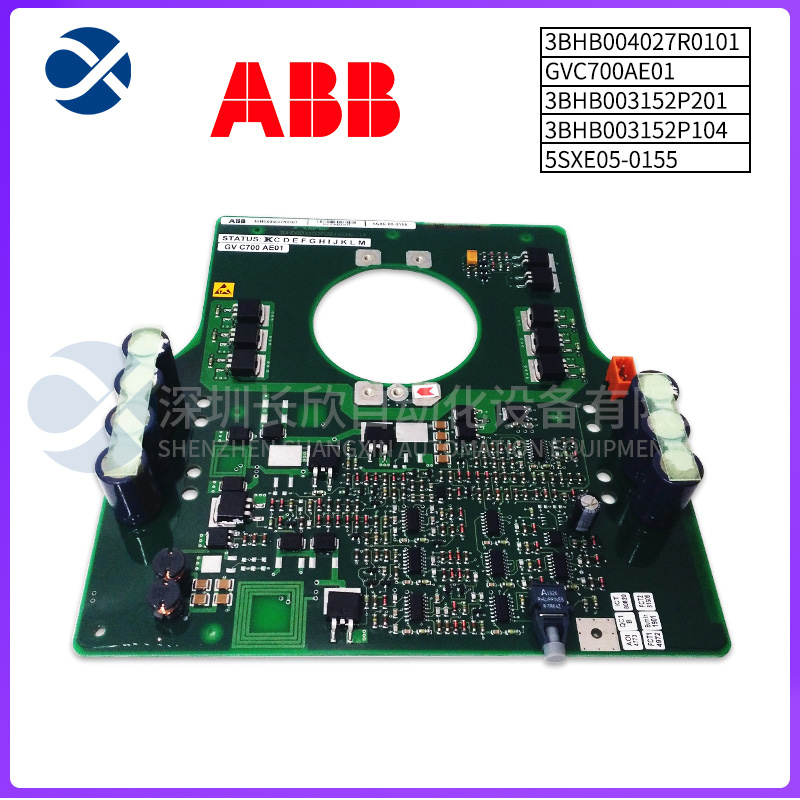

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101 ABB GRID BREAKER UNIT GBU72 3BHE055094R0002 / 3BHE031197R0001 / 3BHB030310R0001 In stock!!! Interested parties please contact us for negotiation

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: