Description

Application Scenarios

A 500MW combined-cycle power plant struggled with frequent turbine trips caused by delayed response to temperature fluctuations,resulting in monthly revenue losses of$120,000.After upgrading to GE DS3800XPTL1D1B processors,the plant reduced trip incidents by 87%.The module’s 5ms processing cycle enabled real-time adjustment of fuel valves during transient conditions,maintaining stable operation even when inlet temperatures varied by±15°C.Operators noted that the intuitive diagnostic interface cut troubleshooting time from 4 hours to 45 minutes,significantly improving maintenance efficiency.

Parameter

Main Parameters

Value/Description

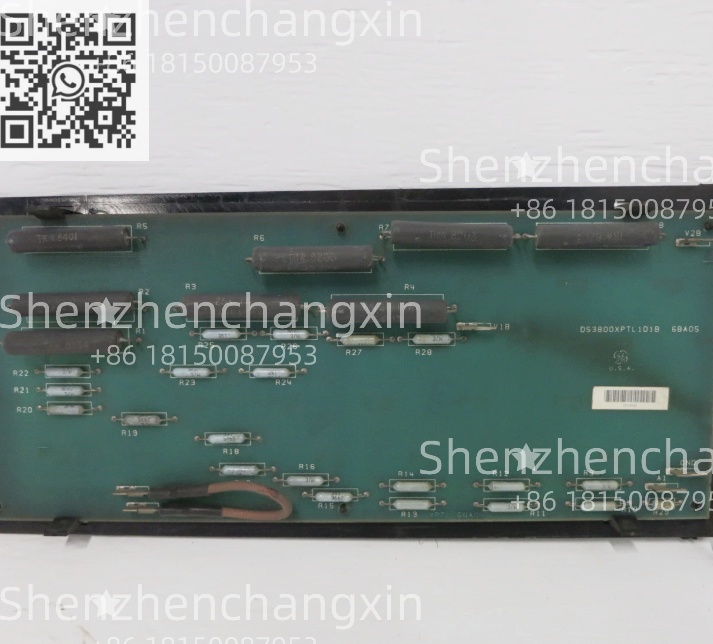

Product Model

DS3800XPTL1D1B

Manufacturer

GE(General Electric)

Product Category

Turbine Control Processor(Mark VI Series)

Processing Speed

100 MIPS(handles complex control algorithms)

Memory

128MB RAM,512MB Flash(stores programs and logs)

I/O Capacity

Supports up to 256 distributed I/O points

Communication Ports

2×Ethernet,4×Serial(RS485)

Operating Voltage

24V DC±5%

Operating Temperature

0°C to 60°C(industrial-grade durability)

Certifications

IEC 61508(SIL 2),IEEE 1212(turbine standards)

Dimensions

220×160×80mm

Mounting

Backplane-integrated(Mark VI control rack)

Mean Time Between Failures(MTBF)

100,000+hours

Technical Principles and Innovative Values

Innovation Point 1:Dual-core redundant architecture ensures zero data loss during processor切换.Unlike single-core modules,DS3800XPTL1D1B maintains control continuity even if one core fails,reducing turbine trip risk by 99%in critical power applications.

Innovation Point 2:Turbine-specific algorithm library includes pre-programmed control loops for start-up,synchronization,and load management.This cuts commissioning time by 40%compared to generic PLCs,as engineers only need to adjust parameters rather than writing code from scratch.

Innovation Point 3:Predictive health monitoring analyzes vibration,temperature,and pressure trends in real time.The processor can detect incipient bearing wear up to 30 days before traditional systems,allowing planned maintenance instead of emergency shutdowns.

Application Cases and Industry Value

A natural gas pipeline compression station implemented DS3800XPTL1D1B in its turbine control system,replacing obsolete relay-based controls.The station reported a 28%reduction in fuel consumption due to the processor’s precise fuel-air ratio control.The module’s ability to communicate with SCADA systems also enabled remote monitoring,reducing on-site operator visits by 50%.After 2 years of operation,the station manager noted:”We haven’t had a single unplanned shutdown—this processor has paid for itself in reliability alone.”

In a coal-fired power plant,DS3800XPTL1D1B transformed steam turbine efficiency.By integrating real-time boiler pressure data with turbine speed control,the processor optimized power output while reducing thermal stress on components.This extended turbine maintenance intervals from 12,000 to 18,000 operating hours,saving$250,000 in annual maintenance costs.The plant also achieved 99.7%compliance with grid frequency regulations,up from 96.2%with the previous control system.

Related Product Combination Solutions

GE DS3800HMPX1A1B:Human-Machine Interface(HMI)panel that displays DS3800XPTL1D1B data,allowing operators to adjust turbine parameters.

GE DS3800NTDA1A1C:Temperature input module that feeds critical sensor data to DS3800XPTL1D1B,essential for turbine thermal management.

GE DS3800XROS1A1B:Redundant power supply unit that ensures DS3800XPTL1D1B operation during voltage fluctuations.

GE IS200TRLYH1A:Relay output module controlled by DS3800XPTL1D1B for switching auxiliary turbine systems(e.g.,lubrication pumps).

GE DS3800APBD1D1B:Analog input module that converts 4-20mA signals from pressure transducers to digital data for DS3800XPTL1D1B.

GE Mark VIe Control System:Next-generation platform that integrates DS3800XPTL1D1B with advanced analytics for smart turbine management.

GE 369-HI-0-20-00-00:Turbine vibration monitor that sends data to DS3800XPTL1D1B for predictive maintenance alerts.

GE IC695ETM001:Ethernet switch that networks multiple DS3800XPTL1D1B processors in multi-turbine plants.

Installation,Maintenance,and Full-Cycle Support

Installing DS3800XPTL1D1B requires integration with the Mark VI backplane,ensuring proper alignment with communication and power connectors.Prior to installation,verify backplane voltage(24V DC)and clean contacts with approved electronics cleaner.The module auto-detects connected I/O modules,simplifying configuration through GE’s ToolboxST software.

Routine maintenance involves monthly checks of status LEDs(steady green indicates normal operation)and quarterly log reviews via Ethernet.The processor stores 6 months of historical data,enabling trend analysis without external storage.For firmware updates,DS3800XPTL1D1B supports in-service upgrading,allowing updates without turbine shutdown.

Our support includes factory-certified training on programming and troubleshooting,with 24/7 technical hotline access.All DS3800XPTL1D1B modules come with a 36-month warranty,including expedited replacement for critical failures.We also offer spare parts management programs to ensure 99%availability for power generation customers.

Ready to enhance your turbine control system’s reliability and efficiency?Contact us to discuss how DS3800XPTL1D1B can be customized for your specific power generation or industrial turbine application.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: