Description

Application Scenarios

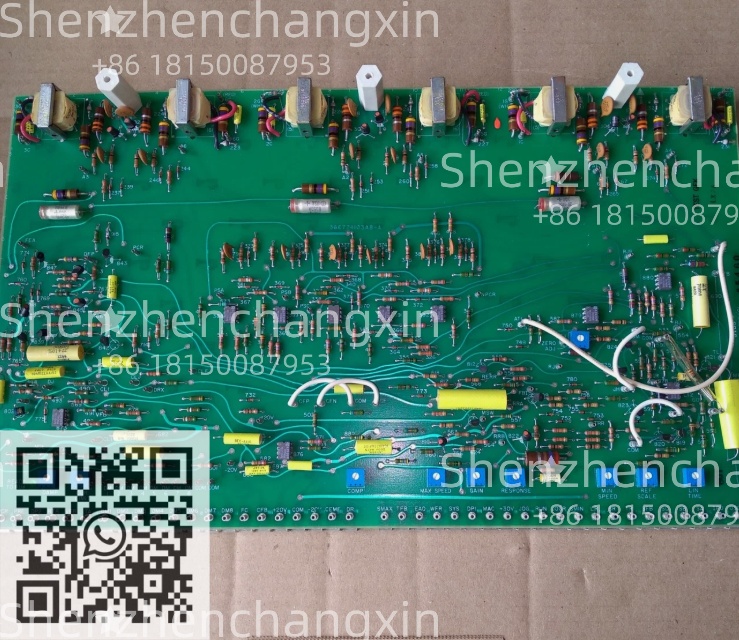

At a combined-cycle power plant in North America,operators faced recurring nuisance trips due to aging turbine protection hardware.The root cause was traced to a degraded trip logic board in the Mark VIe system that failed to maintain signal integrity under thermal stress.After replacing the legacy unit with a genuine GE 36C774I02AB-A 3183 I93X530BBG0I module,the plant achieved zero spurious trips over the next 18 months.The GE 36C774I02AB-A 3183 I93X530BBG0I’s dual-channel architecture and hardened circuitry ensured reliable trip command execution even during grid disturbances.This case underscores how a single,precision-engineered safety module can be the difference between stable power delivery and costly,unplanned outages in high-availability energy facilities.

Parameter

Main Parameters Value/Description

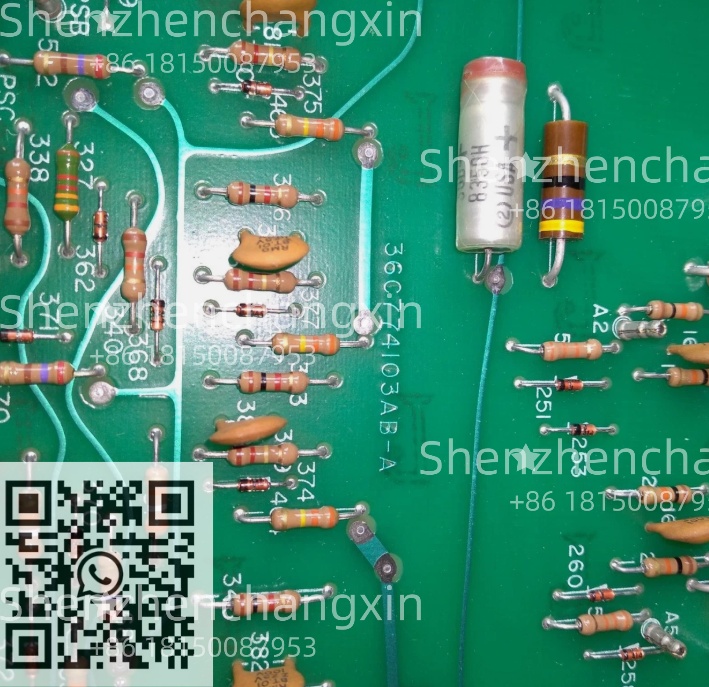

Product Model 36C774I02AB-A 3183 I93X530BBG0I

Manufacturer GE(General Electric)

Product Category Turbine Protection&Trip Logic Module

Function Dual-Channel Trip Solenoid Driver

Input Voltage 24–125 V DC(Typical 110V DC)

Output Type Relay/Solid-State(Trip Command)

Redundancy Level 2-Channel(A&B)Independent Paths

Response Time<10 ms(Trip Command Execution)

Communication Interface Mark VIe Backplane Bus(TurbineNet)

Isolation Voltage>1500 V AC(Field to Logic)

Environmental Rating Operating Temp:-10°C to+70°C

Compliance IEC 61508(SIL 3 Capable),IEEE 344,GEK 107540

Mounting Type 19”Rack,Standard Mark VIe Chassis

Diagnostics Built-in LED Status,Backplane Monitoring

Technical Principles and Innovative Values

Innovation Point 1:Dual-Channel Fault-Tolerant Architecture

The GE 36C774I02AB-A 3183 I93X530BBG0I employs a fully redundant A/B channel design,where each path independently monitors trip conditions and drives solenoids.This 2oo2(two-out-of-two)logic ensures no single point of failure can prevent a valid trip,meeting SIL 3 requirements for functional safety in turbine protection systems.

Innovation Point 2:Deterministic High-Speed Response

With a trip command execution time of under 10 milliseconds,the GE 36C774I02AB-A 3183 I93X530BBG0I outperforms generic PLCs.This speed is critical during overspeed,fire,or bearing failure events,where every millisecond delays can lead to catastrophic mechanical damage.

Innovation Point 3:Seamless Mark VIe Integration

Unlike third-party replacements,the GE 36C774I02AB-A 3183 I93X530BBG0I integrates natively with the Mark VIe backplane,enabling real-time diagnostics,firmware updates,and synchronization with other protection modules(e.g.,I93X,I94X series)without custom programming or gateways.

Innovation Point 4:Hardened for Harsh Industrial Environments

Designed for power plant control rooms and turbine enclosures,the GE 36C774I02AB-A 3183 I93X530BBG0I withstands high EMI,voltage transients,and thermal cycling.Its conformal coating and robust power filtering ensure reliability in environments where standard industrial electronics would fail.

Application Cases and Industry Value

At an offshore LNG facility,the main gas turbine’s protection system required a complete refresh due to obsolescence.Engineers selected the GE 36C774I02AB-A 3183 I93X530BBG0I as the core trip driver,integrating it with existing I93X series I/O.During commissioning,a simulated overspeed test confirmed the module’s reliability—trip commands were issued and verified in 8.3 ms,well within safety margins.The operator reported,“The GE 36C774I02AB-A 3183 I93X530BBG0I restored confidence in our safety system.It’s not just a board—it’s peace of mind.”

In another case,a petrochemical plant upgraded its steam turbine control system.By deploying the GE 36C774I02AB-A 3183 I93X530BBG0I,they reduced trip system maintenance by 60%due to its self-diagnostics and reduced false alarms.The module’s long-term reliability contributed to a 22%improvement in turbine availability,directly impacting production output.

Related Product Combination Solutions

I93X530ABG01:Companion I/O module for speed and vibration monitoring,often paired with GE 36C774I02AB-A 3183 I93X530BBG0I in turbine protection racks.

Mark VIe Controller(IC695):Main processor that coordinates with GE 36C774I02AB-A 3183 I93X530BBG0I for comprehensive turbine control and protection logic.

I94X Series Modules:Redundant communication and interface boards that extend the safety network,working in tandem with GE 36C774I02AB-A 3183 I93X530BBG0I.

TurbineNet Switch(ICP75):High-speed Ethernet backbone enabling real-time data exchange between GE 36C774I02AB-A 3183 I93X530BBG0I and other Mark VIe components.

GE 36C774I01AB-A:Earlier revision of the trip logic board;GE 36C774I02AB-A 3183 I93X530BBG0I is a direct upgrade with enhanced diagnostics.

IC200 Series I/O:General-purpose modules that complement the safety-critical functions of GE 36C774I02AB-A 3183 I93X530BBG0I in hybrid control schemes.

Speedtronic Toolbox:Configuration and diagnostic software used to monitor and validate the operation of GE 36C774I02AB-A 3183 I93X530BBG0I in real time.

GEK 107540 Documentation Set:Official technical manual that defines the installation,testing,and maintenance procedures for GE 36C774I02AB-A 3183 I93X530BBG0I.

Installation,Maintenance,and Full-Cycle Support

Installing the GE 36C774I02AB-A 3183 I93X530BBG0I requires alignment with GE’s Mark VIe chassis specifications.The module slides into a designated slot on the 19”rack and connects via a high-density backplane.Field wiring for trip solenoids and status feedback must follow GE’s separation and shielding guidelines to maintain signal integrity.Power-up and integration are automatic,with the module registering on the TurbineNet bus and syncing with the controller.Its front-panel LEDs provide immediate visual feedback on power,run,and fault status.

Routine maintenance is minimal but critical.Periodic functional testing(e.g.,simulated trip tests)ensures the GE 36C774I02AB-A 3183 I93X530BBG0I remains operational.The module’s built-in diagnostics report health data to the Mark VIe HMI,enabling predictive maintenance.When replacement is needed,the unit can be swapped under power in most configurations,minimizing downtime.We provide full technical support,including configuration validation,firmware compatibility checks,and lifecycle management for legacy GE turbine control systems.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: