Product introduction

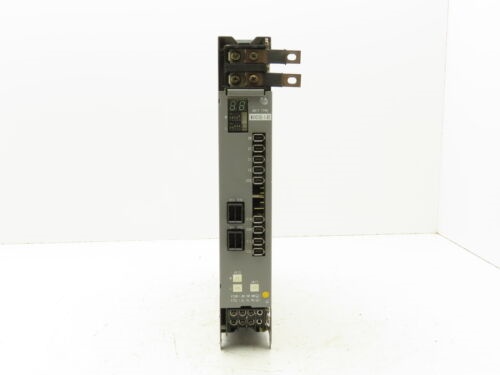

The Okuma MIV0102-1-B1 servo drive is a state-of-the-art component in the industrial automation landscape,especially renowned for its pivotal role in precision-oriented machining processes.As an integral part of Okuma’s esteemed MIV series,the MIV0102-1-B1 is meticulously engineered to deliver unrivaled performance.

Functioning as the crucial link between the control system and the servo motor,the MIV0102-1-B1 precisely governs the motor’s speed,torque,and position.Leveraging Okuma’s advanced control algorithms,this servo drive guarantees that the motor responds instantaneously and accurately to control commands.This level of precision is of utmost importance in applications like high-end CNC machine tools,where even the slightest deviation can lead to sub-standard results.The MIV0102-1-B1 seamlessly operates within Okuma’s comprehensive automation ecosystem,integrating harmoniously with other Okuma components.This integration creates a highly efficient and reliable automation solution that can meet the most demanding industrial requirements.

Core advantages and technical highlights

Exceptionally high-precision control

The Okuma MIV0102-1-B1 sets a new standard for precision in motor control.Its cutting-edge control technology allows it to achieve nanometer-level accuracy in motor positioning.In a high-precision CNC machining center used for aerospace component manufacturing,for example,the MIV0102-1-B1 ensures that the cutting tool moves with micron-level precision.This results in the production of components with extremely tight tolerances,which are essential for the safe and efficient operation of aircraft.

Robust and reliable construction

Built with top-grade materials,the MIV0102-1-B1 is designed to endure the harshest industrial environments.It has excellent resistance to vibrations,which are common in manufacturing plants with multiple operating machines.Additionally,it can withstand significant electrical noise and shocks,ensuring continuous and stable operation.In a factory with large-scale industrial equipment,the MIV0102-1-B1 can function flawlessly without being affected by the surrounding electromagnetic interference.

Easy and flexible integration

This servo drive is engineered with integration in mind.It supports a wide range of industrial communication protocols,making it compatible with various control systems.Whether it’s a new installation in a modern smart factory or an upgrade of an existing automation system,the MIV0102-1-B1 can be quickly and effortlessly integrated.This reduces downtime during system implementation or upgrade,minimizing production losses and maximizing efficiency.

Typical application scenarios

The Okuma MIV0102-1-B1 finds extensive applications across multiple industries.In the automotive industry,it plays a vital role in the production of engine components.For instance,when machining engine blocks,the MIV0102-1-B1 controls the servo motors of CNC machine tools.It ensures that drilling operations create holes with precise diameters and depths,milling operations achieve smooth surfaces,and boring operations result in accurate internal diameters.This high-precision machining improves the performance and durability of engines.

In the medical device manufacturing industry,precision is critical.The MIV0102-1-B1 is used in the production of surgical instruments such as scalpels and forceps.It enables the precise shaping and finishing of these instruments,ensuring their sharpness and functionality.In the case of implantable devices like hip implants,the MIV0102-1-B1 helps in achieving the exact dimensions required for a perfect fit within the human body.

In the electronics industry,where miniaturization and high-precision manufacturing are the norm,the MIV0102-1-B1 is used in the production of printed circuit boards(PCBs).It controls the motors that position the drilling and soldering equipment,ensuring that components are placed accurately on the PCB,which is crucial for the proper functioning of electronic devices.

Related model recommendations

MIV0101-1-B1:Belonging to the same MIV series as the MIV0102-1-B1,it has a relatively lower power capacity.It is suitable for applications where less power is required,such as in small-scale hobbyist CNC machines or in some light-duty industrial processes where cost-effectiveness and a smaller footprint are priorities.

MIV0103-1-B1:Also from the MIV series,this model offers enhanced performance in terms of speed and torque compared to the MIV0102-1-B1.It is ideal for applications that involve heavy-duty machining of large-sized workpieces,like in the production of large molds or in the manufacturing of heavy machinery components.

MIV0202-1-B2:Although from a different variant within Okuma’s servo drive product line,it can be a suitable alternative in certain scenarios.It may have different interface configurations or control features that could be more suitable for specific automation setups,such as those with unique communication requirements or in systems that need to interface with legacy equipment.

MIV15-1-B1:This model has a different power rating.It can be used in scenarios where a more powerful or less powerful drive is needed compared to the MIV0102-1-B1.For example,in applications with motors that have non-standard power requirements or in systems where energy efficiency is a primary concern and a different power-sized drive can optimize the overall energy consumption.

MIV22A-1-B1:Similar to the above,it has a distinct power capacity.It may be more appropriate for applications with higher-power motor requirements,such as in large-scale industrial machinery like high-speed presses or in conveyor systems that need to move heavy loads over long distances.

Installation,commissioning and maintenance instructions

Installation preparation

Before installing the Okuma MIV0102-1-B1,ensure that the installation area is clean,dry,and free from any contaminants.Gather the necessary tools,such as screwdrivers,wrenches,and wire strippers.Thoroughly review the detailed installation manual provided by Okuma.It is crucial to turn off all power sources associated with the automation system to prevent electrical accidents during installation.Additionally,carefully check the compatibility of the MIV0102-1-B1 with the motor and control system it will be connected to.This includes verifying voltage ratings,communication protocol compatibility,and mechanical mounting requirements.

Maintenance suggestions

For the daily maintenance of the MIV0102-1-B1,regularly inspect the drive for any visible signs of physical damage,such as cracks,loose wires,or overheating marks.Monitor the operating temperature of the drive using the built-in temperature sensors or external monitoring devices.An increase in temperature could indicate a potential issue.In case of any abnormal behavior,such as erratic motor control or communication failures,refer to the comprehensive troubleshooting guide in the user manual.When replacing spare parts,always use genuine Okuma parts to ensure optimal performance and compatibility.Periodically update the drive’s firmware to benefit from the latest features,performance improvements,and bug fixes.

Service and guarantee commitment

Okuma is committed to the quality of the MIV0102-1-B1 servo drive.We offer a comprehensive quality assurance program that covers any defects in materials or workmanship.The product comes with a standard warranty period,during which Okuma will promptly address any issues that arise.Our after-sales service is second-to-none,with a dedicated team of highly skilled technical experts.Whether you need technical advice during the installation process,assistance with troubleshooting during operation,or help with spare parts replacement,our team is just a phone call or an email away.We are dedicated to ensuring that the MIV0102-1-B1 serves you reliably for the long term,enhancing the efficiency and productivity of your industrial operations.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953 SOLEMN COMMITMENT 1. For all items, modules, and cards sold by our company, if any quality problems occur during normal use within the warranty period, we will provide free replacements without any excuse or delay. 2. For non-discontinued materials and equipment that are out of the warranty period, we only charge the cost of relevant accessories for quality problems. 3. For discontinued materials and equipment, we provide alternative models and equipment replacement process services. 4. For the materials and equipment purchased by customers, we offer lifetime free system software upgrades and provide relevant technical documents for free. 5. We regularly follow up on the usage of the materials purchased by customers and promptly solve any problems. 6. Our company’s hotline provides 24-hour service, and we will respond to customers’ questions within 1 hour. 7. For any other matters not covered, our company adheres to the attitude of “thoughtful service and full responsibility” and solves problems from the customer’s perspective in a practical way. With a serious and rigorous corporate style, we wholeheartedly serve every customer. The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as: ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse, etc. The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers, and can directly purchase from abroad, providing equipment and spare parts from different countries and manufacturers. We supply directly from abroad, without middlemen, reducing the cost of use. There is really no middleman who can make a price difference! ! If you have any defects or need to import PLC, DCS spare parts, please contact our team, we will help you find reliable and high-quality products super quickly, while shortening the delivery time to ensure that your equipment can operate normally in the right environment. On time. Professionally provide: PLC programmable control system, distributed control system (DCS), safety instrument system (SIS), ESD system, vibration monitoring system, turbine compressor control system (CCS) and other PLC modules, various industrial control systems, system modules, CPU, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion controller, analog input module, analog output module, switch input module, switch output module, module redundancy, power supply module, relay output unit, relay input unit, processing unit. Products are widely used in: electricity, petroleum, mine hoisting, ports, heating, gas, water supply, sewage treatment, metallurgy, papermaking, textile, chemical industry, water conservancy and other modern industrial fields! ABB 5SHY3545L0010/3BHB013088R0001 MOTOROLA MVME2434 MOTOROLA MVME2432 A-B 81001-450-53-R ABB PNI800 WOODWARD 9907-164 NI PXIE-4145 ABB CI871K01 3BSE056797R1 MOTOROLA MVME5500-0161 MOTOROLA MVME5500-0163 EMERSON MVME55006E-0163 GE DS200DCFBG1BJB ABB PPD113B01-10-150000 ABB PM904F 3BDH001002R0001 MOTOROLA MVME2400 FOXBORO H92A0K9V0H00 PIONEER MAGNETICS PM36218B-10P-1-8PH-J GE IC698CPE040-JP EMERSON MVME7100 ABB HPC800K02 ABB SYN5202-0277 ABB HPC800K02(含HC800模块、CP800模块、底座) MOTOROLA MVME5500 MOTOROLA MVME55006E-0163R GE IS215UCVEM09B AMAT 0090-76110 VME PCB ABB 5SHX2645L0002/3HB012961R0001 ABB AO2000-LS25 ABB PM865K01 3BSE031151R1 ABB 5SHX1445H0001 3BHL000391P0101 3BHB003230R0101 5SXE05-0152 KONGSBERG DPS112 GE VMIVME-7750 ABB AO2000-LS25 TRICON 4352B ABB PFSK152 TRICONEX 3009 MOOG D136-001-007 SCANde INTELLISCANDE14-405NM SCANLAB

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: