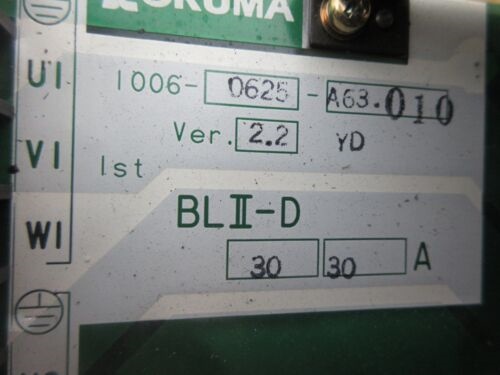

In modern industrial manufacturing,CNC machine tools,as the core equipment of high-precision machining,directly affect product quality and production efficiency.As the”heart”of CNC machine tools,the servo drive system determines the operation accuracy,response speed and stability of the equipment.As a world-renowned machine tool manufacturer,OKUMA’s R&D SERVER DRIVE BLII-D3030A 1006-0625-A63.wbr010 BLII-D30 30A E4809-770-065 original spindle interface control board(hereinafter referred to as”BLII-D3030A control board”)has become the first choice for many high-end manufacturers with its advanced technical architecture and excellent reliability.This article will deeply analyze the technical characteristics,application scenarios and practical value of the control board,and present the technical logic and industry contributions behind it to readers.

I.The core of high efficiency and stability:analysis of technical characteristics

The BLII-D3030A control board is the crystallization of OKUMA based on many years of experience in the research and development of servo drive technology.Its core advantages are reflected in the following aspects:

High-precision spindle control technology

The control board adopts OKUMA’s original TAS-S(Thermo Active Stabilizer-Spindle)spindle thermal displacement control function.By monitoring the temperature change of the spindle,the speed state and stopping time in real time,the system can dynamically compensate for the thermal displacement error.For example,in the case of frequent variable speed machining,the control panel can accurately predict the displacement deviation caused by the thermal expansion of the spindle and automatically adjust the compensation amount to ensure that the machining accuracy is always maintained at the micron level.This technology is especially suitable for scenarios with extremely high dimensional accuracy in aerospace,precision mold manufacturing and other fields.

Environmental Adaptability Optimization Design

In view of the impact of ambient temperature fluctuation on the machining accuracy of the machine tool,the BLII-D3030A control board integrates the TAS-C(Thermo Active Stabilizer-Construction)ambient thermal displacement control function.Through the sensor network arranged in the key parts of the machine tool,the system can capture the ambient temperature change in real time,and combine the thermal displacement model of the machine tool structure to actively adjust the motion parameters of each axis.For example,when multi-station continuous machining in a large machining center,the control plate can effectively suppress the size deviation of the workpiece caused by the ambient temperature gradient and improve the consistency of batch processing.

Intelligent Troubleshooting and Protection

The control board has built-in multiple protection mechanisms,including fault monitoring modules such as overcurrent,overvoltage,overheating,encoder anomalies,etc.When the system detects potential risks,it immediately triggers an alert or a safe downtime to avoid damage to the device.In addition,the control board supports real-time recording and uploading of fault codes,and maintenance personnel can quickly locate the root cause of the problem through OKUMA’s intelligent diagnostic platform.For example,an auto parts manufacturer used this function to solve downtime caused by encoder power failure within 2 hours,greatly shortening the repair time.

Compatibility and scalability design

The BLII-D3030A control board adopts a standardized interface design,is compatible with OKUMA multi-series CNC machine tools(such as UNIVERSAL CENTER MU series,SPACE CENTER MA series,etc.),and supports the integration of third-party CNC systems.Its modular structure is convenient for hardware upgrade and function expansion.Enterprises can flexibly configure high-speed communication modules or advanced control algorithms according to the needs of the production line to meet the needs of intelligent manufacturing upgrades.

II.Practical application:empower multi-industry precision manufacturing

The BLII-D3030A control board has been verified in benchmark projects in many industries around the world.The following are typical cases:

Precision mold machining:A well-known mold enterprise adopts the OKUMA VTM-2000YB composite machining center equipped with the control board,which realizes that the mold cavity machining error is controlled within±3μm and the surface roughness Ra≤0.8μm.Through TAS-S technology,the contour accuracy attenuation caused by the thermal displacement of the spindle during high-speed milling is effectively solved.

New energy vehicle motor shell processing:A motor manufacturing plant deploys MCR-A5CII,a gantry machining center of the BLII-D3030A control panel.Through the ambient thermal displacement compensation function,under the environment of temperature fluctuation of±5°C in the workshop,the positioning hole position accuracy of the motor shell is better than the ISO 6 standard.

Mass production of medical device parts:A medical equipment manufacturer uses the high-speed response characteristics of the control board to shorten the processing beat to 60%of the traditional system.At the same time,preventive maintenance is achieved through the intelligent diagnostic system,and the failure rate of the equipment is reduced by 40%.

III.User evaluation and expert views

Industry users’evaluation of the BLII-D3030A control board is concentrated in the three dimensions of stability,precision guarantee and easy maintenance.The equipment director of a foreign-funded machining enterprise said:”In the past,when using other brands of servo systems,the machining errors caused by temperature changes needed frequent downtime adjustment,and the TAS-C function of BLII-D3030A completely got us out of this problem,and the production efficiency improved significantly.”

Wang Gong,a senior numerical control expert,pointed out:”OKUMA extends thermal displacement control technology from a single spindle to the whole machine structure.This innovation breaks the dependence of traditional servo systems on environmental conditions.The intelligent compensation algorithm of BLII-D3030A not only improves machining accuracy,but also reduces the input cost of enterprises in the ambient temperature control system,reflecting the inclusive industrial value of technology.

IV.Common troubleshooting and maintenance suggestions

Although the BLII-D3030A control board is highly reliable,the following points still need to be paid attention to in practical applications:

Examples of troubleshooting

LED lights continue to be red:The common cause is overvoltage/underpressure or overheat protection.You need to check the stability of the power input and clean the radiator dust.

Motor stall:Check whether the encoder connection is loose,or try to adjust the HALL phase setting(refer to the control board manual).

No display failure:Confirm that the power supply voltage meets the standard(see the equipment parameter table for the minimum requirements)and check whether the control box is wiring correctly.

Maintenance suggestions

Regularly use OKUMA official diagnostic tools for systematic health checks to generate maintenance reports.

In an environment with more dust or cutting fluid,it is recommended to install a protective isolation device to extend the service life of the control plate.

To establish a spare parts library,it is recommended to reserve 1-2 sets of key modules(such as IPM power module)to deal with sudden failures.

V.Future Outlook:Integration of Intelligence and Greening

With the advancement of Industry 4.0,the BLII-D3030A control board is expected to further integrate AI technology to realize adaptive parameter optimization and predictive maintenance.In OKUMA’s latest Green-Smart Machine concept,the control board has been listed as a core component to help the machine tool achieve a balance of”high accuracy and low energy consumption”through a dynamic energy consumption adjustment algorithm.In the future,it may become an important carrier of”carbon neutralization”technology in intelligent manufacturing.

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures. Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953 SOLEMN COMMITMENT 1. For all items, modules, and cards sold by our company, if any quality problems occur during normal use within the warranty period, we will provide free replacements without any excuse or delay. 2. For non-discontinued materials and equipment that are out of the warranty period, we only charge the cost of relevant accessories for quality problems. 3. For discontinued materials and equipment, we provide alternative models and equipment replacement process services. 4. For the materials and equipment purchased by customers, we offer lifetime free system software upgrades and provide relevant technical documents for free. 5. We regularly follow up on the usage of the materials purchased by customers and promptly solve any problems. 6. Our company’s hotline provides 24-hour service, and we will respond to customers’ questions within 1 hour. 7. For any other matters not covered, our company adheres to the attitude of “thoughtful service and full responsibility” and solves problems from the customer’s perspective in a practical way. With a serious and rigorous corporate style, we wholeheartedly serve every customer. The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as: ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse, etc. The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers, and can directly purchase from abroad, providing equipment and spare parts from different countries and manufacturers. We supply directly from abroad, without middlemen, reducing the cost of use. There is really no middleman who can make a price difference! ! If you have any defects or need to import PLC, DCS spare parts, please contact our team, we will help you find reliable and high-quality products super quickly, while shortening the delivery time to ensure that your equipment can operate normally in the right environment. On time. Professionally provide: PLC programmable control system, distributed control system (DCS), safety instrument system (SIS), ESD system, vibration monitoring system, turbine compressor control system (CCS) and other PLC modules, various industrial control systems, system modules, CPU, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion controller, analog input module, analog output module, switch input module, switch output module, module redundancy, power supply module, relay output unit, relay input unit, processing unit. Products are widely used in: electricity, petroleum, mine hoisting, ports, heating, gas, water supply, sewage treatment, metallurgy, papermaking, textile, chemical industry, water conservancy and other modern industrial fields! ABB 5SHY3545L0010/3BHB013088R0001 MOTOROLA MVME2434 MOTOROLA MVME2432 A-B 81001-450-53-R ABB PNI800 WOODWARD 9907-164 NI PXIE-4145 ABB CI871K01 3BSE056797R1 MOTOROLA MVME5500-0161 MOTOROLA MVME5500-0163 EMERSON MVME55006E-0163 GE DS200DCFBG1BJB ABB PPD113B01-10-150000 ABB PM904F 3BDH001002R0001 MOTOROLA MVME2400 FOXBORO H92A0K9V0H00 PIONEER MAGNETICS PM36218B-10P-1-8PH-J GE IC698CPE040-JP EMERSON MVME7100 ABB HPC800K02 ABB SYN5202-0277 ABB HPC800K02(含HC800模块、CP800模块、底座) MOTOROLA MVME5500 MOTOROLA MVME55006E-0163R GE IS215UCVEM09B AMAT 0090-76110 VME PCB ABB 5SHX2645L0002/3HB012961R0001 ABB AO2000-LS25 ABB PM865K01 3BSE031151R1 ABB 5SHX1445H0001 3BHL000391P0101 3BHB003230R0101 5SXE05-0152 KONGSBERG DPS112 GE VMIVME-7750 ABB AO2000-LS25 TRICON 4352B ABB PFSK152 TRICONEX 3009 MOOG D136-001-007 SCANde INTELLISCANDE14-405NM SCANLAB

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: