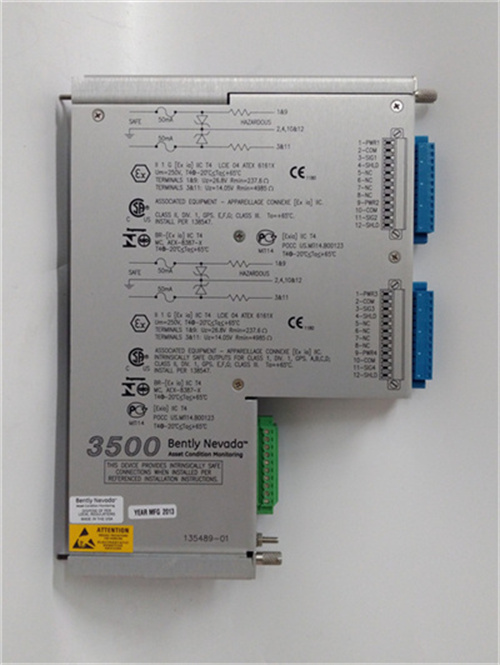

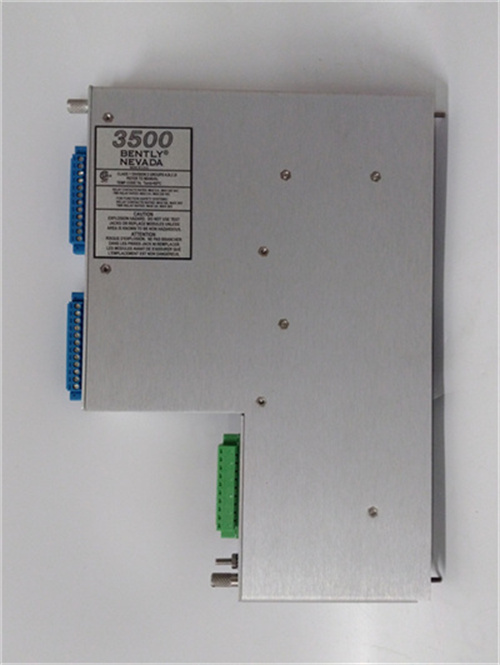

BENTLY 135462-01 is the core module of the Bentley Nevada 3500 monitoring system.It is specially designed for vibration monitoring and fault diagnosis of industrial rotating machinery.It has high-precision,multi-channel data acquisition and remote control functions.The following is a comprehensive description of its core features and application scenarios:

I.Core functions and technical characteristics

Vibration monitoring and data analysis

Collect the vibration data of rotating machinery(such as steam turbines,compressors,pumps,etc.)in real time,support static(displacement)and dynamic(vibration)measurement,and realize the conversion of physical quantity to electrical signals through eddy current sensors or magnetoelectric sensors.

Provide advanced diagnostic functions to identify mechanical faults such as bearing wear,misalignment and loosening,and generate trend analysis reports.

Modularization and scalability

It adopts a modular design,supports the flexible configuration of sensor input types(such as vibration,temperature,speed),and is compatible with the front device,probe and expansion module of the Bentley 3500 system.

Support multi-channel monitoring(the specific number of channels depends on the model)and can monitor the vibration parameters of multiple devices or different locations at the same time.

Communication and remote control

Integrated industrial communication protocols(such as Modbus,Profibus)support data interaction with PLC,DCS systems and upper computers.

It provides a remote access interface,which allows real-time viewing of equipment status and adjusting parameters through the central control platform to reduce on-site maintenance requirements.

Environmental adaptability

It conforms to industrial protection standards(such as IP67)and adapts to harsh environments such as high temperature,high humidity and dust.

Through EMC certification,it has strong resistance to electromagnetic interference and is suitable for complex industrial scenarios such as power plants and chemical plants.

II.Typical application scenarios

Rotating machinery monitoring

It is used for vibration and displacement monitoring of key equipment such as steam turbines,compressors and generators to prevent sudden shutdowns caused by mechanical failures.

Predictive maintenance

Through long-term vibration data trend analysis,we can warn of potential failures in advance,optimize maintenance plans,and reduce the risk of unplanned downtime.

Industrial automation system integration

As an extension module of the 3500 monitoring system,it works with PLC,HMI and other equipment to realize the automatic control and fault diagnosis of the production process.

III.Technical parameters(comprehensive multi-model information)

Input signal range:±10V(optional±5V or±2.5V)

Measurement accuracy:±0.05%FS(full range error)

Operating temperature:-25℃~+70℃

Power supply requirements:24V DC(±10%)

Communication interface:Ethernet,RS232/485 serial port

Choose Shenzhen Changxin for worry-free after-sales service and high-quality products. We only cooperate with first-tier brand manufacturers in the industry. Our products are imported and comprehensive. We provide thoughtful pre-sales service, communicating multiple times with customers about product models, quality, prices, and delivery schedules to jointly confirm the solutions and address users’ concerns in advance. Business execution is in place, ensuring on-time delivery of ordered products and formulating a comprehensive delivery plan to guarantee the project schedule. We also assist users in handling acceptance procedures.

Our after-sales service is impeccable. For any problems during the warranty period, we only replace, not repair. We never shirk responsibilities or pass the buck when encountering problems. Our service hotline is available 24/7: 18150087953

SOLEMN COMMITMENT

- For all items, modules, and cards sold by our company, if any quality problems occur during normal use within the warranty period, we will provide free replacements without any excuse or delay.

- For non-discontinued materials and equipment that are out of the warranty period, we only charge the cost of relevant accessories for quality problems.

- For discontinued materials and equipment, we provide alternative models and equipment replacement process services.

- For the materials and equipment purchased by customers, we offer lifetime free system software upgrades and provide relevant technical documents for free.

- We regularly follow up on the usage of the materials purchased by customers and promptly solve any problems.

- Our company’s hotline provides 24-hour service, and we will respond to customers’ questions within 1 hour.

- For any other matters not covered, our company adheres to the attitude of “thoughtful service and full responsibility” and solves problems from the customer’s perspective in a practical way. With a serious and rigorous corporate style, we wholeheartedly serve every customer.

The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as: ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse, etc. The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers, and can directly purchase from abroad, providing equipment and spare parts from different countries and manufacturers.

We supply directly from abroad, without middlemen, reducing the cost of use.

There is really no middleman who can make a price difference! !

If you have any defects or need to import PLC, DCS spare parts, please contact our team, we will help you find reliable and high-quality products super quickly, while shortening the delivery time to ensure that your equipment can operate normally in the right environment. On time.

Professionally provide: PLC programmable control system, distributed control system (DCS), safety instrument system (SIS), ESD system, vibration monitoring system, turbine compressor control system (CCS) and other PLC modules, various industrial control systems, system modules, CPU, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion controller, analog input module, analog output module, switch input module, switch output module, module redundancy, power supply module, relay output unit, relay input unit, processing unit.

Products are widely used in: electricity, petroleum, mine hoisting, ports, heating, gas, water supply, sewage treatment, metallurgy, papermaking, textile, chemical industry, water conservancy and other modern industrial fields!

TRICONEX 2058

TRICONEX 2101

TRICONEX 2301

TRICONEX 2351

TRICONEX 2481

TRICONEX 2401

TRICONEX 2553

TRICONEX 2551

TRICONEX 2658

TRICONEX 2652

TRICONEX 2651

TRICONEX 2661

TRICONEX 2660-63

TRICONEX 2700

TRICONEX 2750

TRICONEX 2752

TRICONEX 2755

TRICONEX 2852

TRICONEX 4107

TRICONEX 4315B

TRICONEX 3002

TRICONEX 3003

TRICONEX 3101

TRICONEX 3201

TRICONEX 3301

TRICONEX 3351

TRICONEX 3401

TRICONEX 3607E

TRICONEX 4101

TRICONEX 4119A

TRICONEX 4200

TRICONEX 4201

TRICONEX 4211

TRICONEX 4238

TRICONEX 4320

TRICONEX 4351A

TRICONEX 4409S

TRICONEX 4500

TRICONEX 4507

WhatsApp:+86 18150087953 WeChat: +86 18150087953

WhatsApp:+86 18150087953 WeChat: +86 18150087953  Email:

Email: